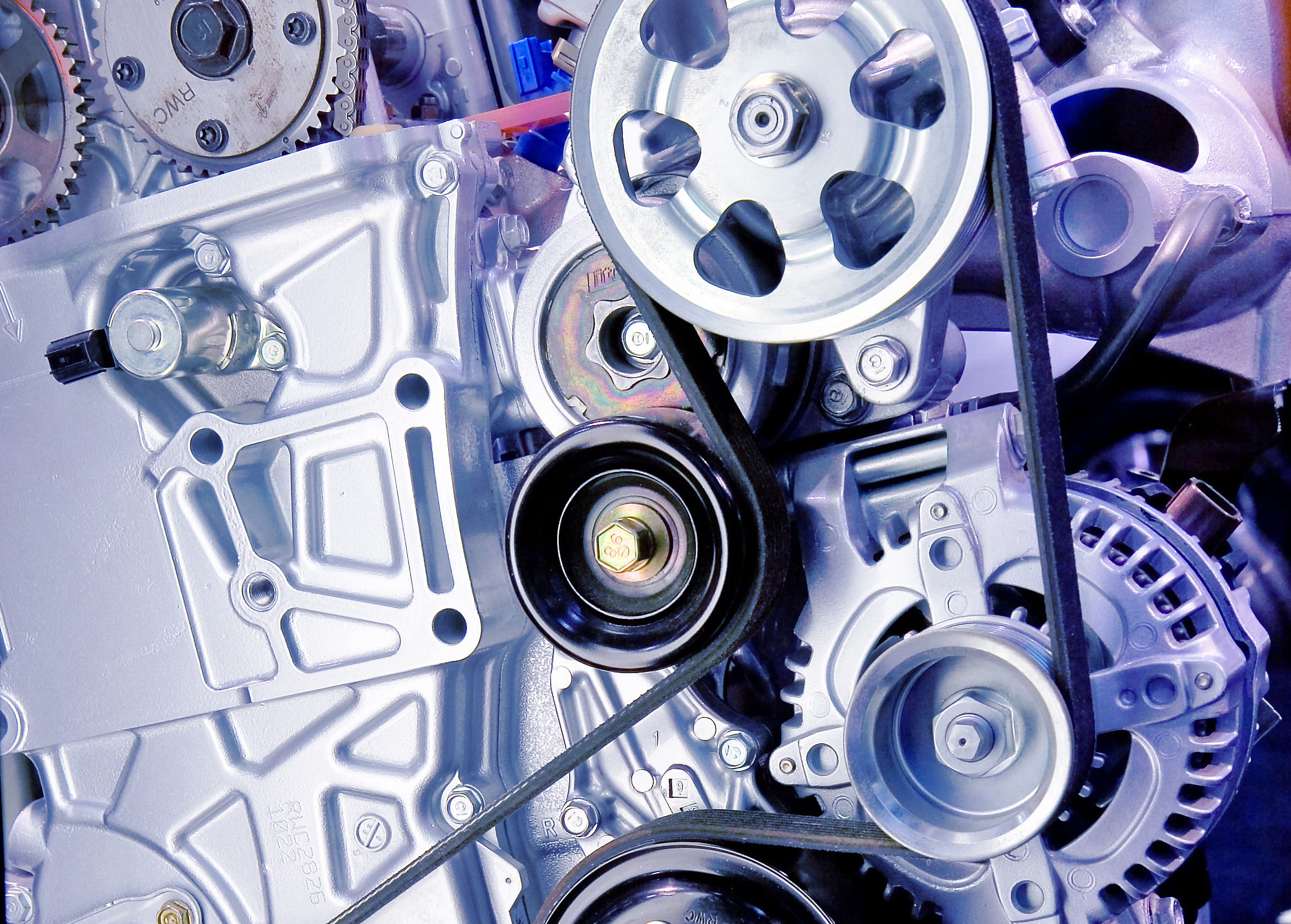

Automotive belts are essential components for smooth engine operation and overall vehicle performance. Without these belts, many of the key systems in your car would not function properly, leading to decreased efficiency, reduced power, and even potential safety hazards.

Understanding the Importance of Automotive Belts

Automotive belts play a crucial role in transmitting power and motion between different components of the engine. They help to drive essential systems such as the alternator, power steering pump, air conditioning compressor, and water pump. When these belts are functioning properly, they ensure that these components receive the necessary power to operate effectively, contributing to the overall smooth and efficient operation of your vehicle.

Types of Automotive Belts

There are several types of automotive belts, each designed for a specific purpose and application. The most common types include:

- Serpentine belts: These are the most widely used type of automotive belts and are responsible for driving multiple accessories, such as the alternator, power steering pump, and air conditioning compressor.

- Timing belts: These belts are critical for synchronizing the timing of the engine’s valves and pistons. They are typically made of reinforced rubber and are designed to withstand high temperatures and loads.

- V-belts: These belts are characterized by their V-shaped cross-section and are used to transmit power between pulleys that are not aligned.

Signs of Worn or Damaged Automotive Belts

As automotive belts age or are subjected to wear and tear, they can become damaged or worn out. Some signs that indicate the need for belt replacement include:

- Squealing or chirping noises: These noises are often caused by worn or slipping belts.

- Dimming lights or reduced electrical power: A failing alternator belt can lead to decreased electrical output, resulting in dimming lights or reduced power to electrical accessories.

- Overheating engine: A broken or slipping water pump belt can prevent the water pump from circulating coolant, leading to engine overheating.

- Difficulty steering: A damaged power steering belt can make steering difficult or unresponsive.

- Cracks, fraying, or glazing: Visual inspection of the belts can reveal cracks, fraying, or glazing, indicating the need for replacement.

Maintaining and Replacing Automotive Belts

To ensure optimal performance and longevity of automotive belts, it’s essential to follow proper maintenance and replacement schedules. Here are some tips:

- Regular inspections: Regularly inspecting belts for signs of wear or damage can help identify potential issues early on.

- Replace belts as recommended: Belts have a specific lifespan and should be replaced according to the manufacturer’s recommendations or when signs of wear appear.

- Use high-quality belts: Investing in high-quality belts from reputable manufacturers can ensure durability and reliability.

- Proper tension: Belts should be properly tensioned to prevent slipping or over-tightening, which can lead to premature failure.

- Avoid overloading: Overloading the engine or accessories can put excessive strain on the belts, leading to damage.

The Different Types of Automotive Belts and Their Functions

In addition to the serpentine, timing, and V-belts mentioned earlier, there are other types of automotive belts that serve specific functions. These include:

- Cogged belts: These belts have cogs or teeth on their inner surface, which provide a positive engagement with the pulleys to prevent slippage.

- Poly-V belts: These belts have multiple ribs instead of a single V-shaped groove, which provides increased surface area for power transmission.

- Flat belts: These belts are thin and flexible and are used in applications where space is limited or where high-speed operation is required.

Interesting Facts about Automotive Belts

Here are some interesting facts about automotive belts:

- The first automotive belt was invented in 1876 by Emile Levassor, a French engineer.

- Automotive belts can be made from various materials, including rubber, leather, and synthetic materials.

- Some high-performance engines use multiple belts to drive different accessories, such as superchargers or turbochargers.

- Belts can be tensioned using various methods, including manual tensioners, automatic tensioners, and hydraulic tensioners.

- Regular belt maintenance can help extend the life of the belts and prevent unexpected breakdowns.

How to Choose the Right Automotive Belt

When choosing an automotive belt, there are several factors to consider:

- Type of belt: The type of belt required will depend on the application and the specific engine.

- Length: The belt must be the correct length to fit properly on the pulleys.

- Width: The belt must be the correct width to provide adequate power transmission.

- Material: The material of the belt should be suitable for the application and the environmental conditions.

- Brand: Choosing a reputable brand can ensure quality and reliability.

Conclusion of Automotive Belts: Essential Components For Smooth Operation And Performance

Automotive belts are vital components that play a crucial role in the smooth and efficient operation of vehicles. By understanding the different types of belts, their functions, and proper maintenance practices, you can ensure that your vehicle performs at its best and avoid costly breakdowns