In the realm of material science, precise quantification of elasticity and strength is paramount for ensuring the integrity and performance of countless products. The tensile tester emerges as an indispensable tool in this quest, unlocking valuable insights into the mechanical properties of materials.

When choosing materials, it’s not just about appearance or price. Engineers and designers need to consider how a material will perform under stress, especially its ability to stretch and return to its original shape (elasticity) and its resistance to breaking (strength). That’s where tensile testing comes in.

Tensile testing, with its tensile tester, is the gold standard for measuring a material’s mechanical properties. It involves applying a controlled pulling force to a specimen of the material and recording how it responds.

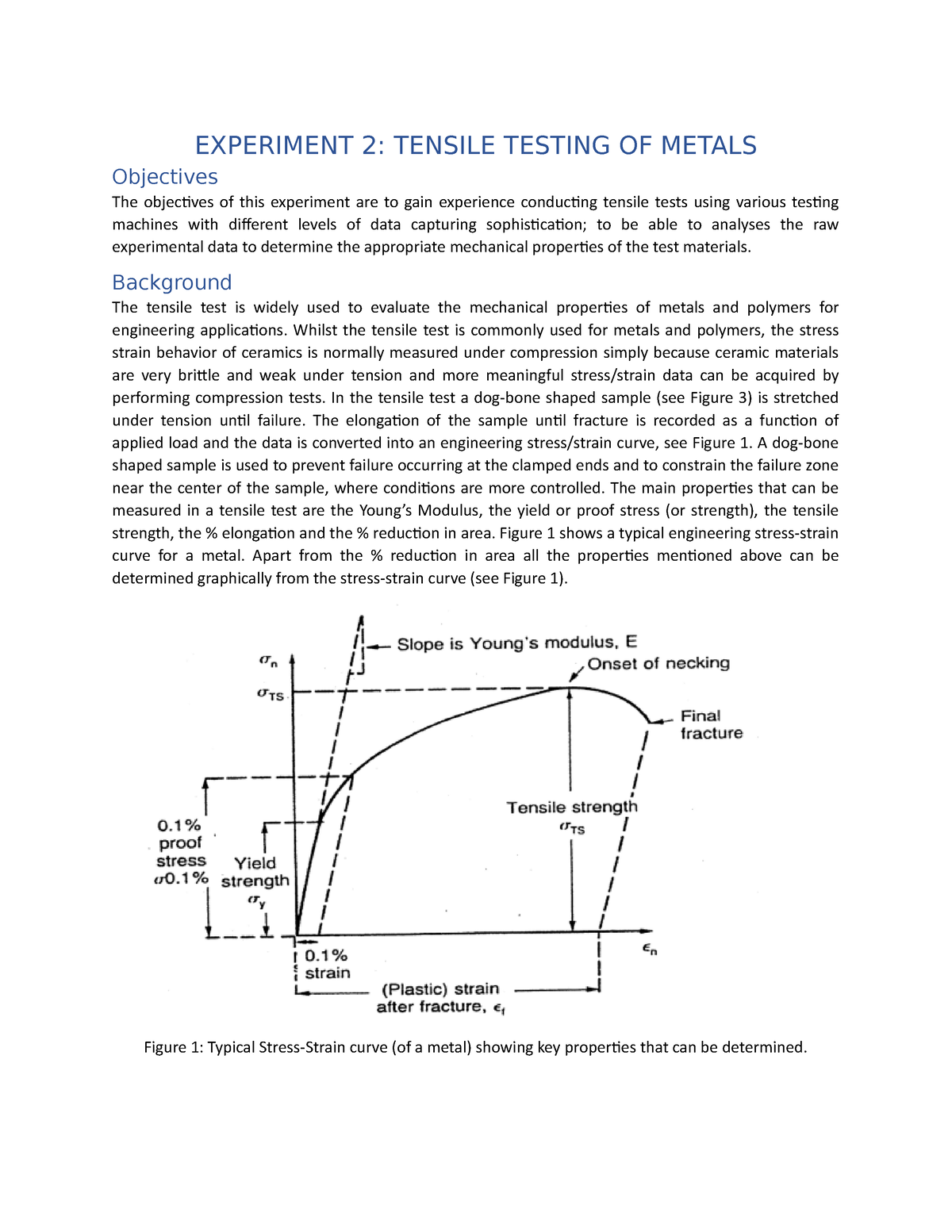

Tensile testing provides a wealth of information about a material’s behavior under tension, including its modulus of elasticity (a measure of stiffness), yield strength (the point at which it starts to deform permanently), ultimate tensile strength (the maximum stress it can withstand), and elongation at break (how much it stretches before breaking).

## 2. Tensile Tester: Quantifying Material Elasticity And Strength

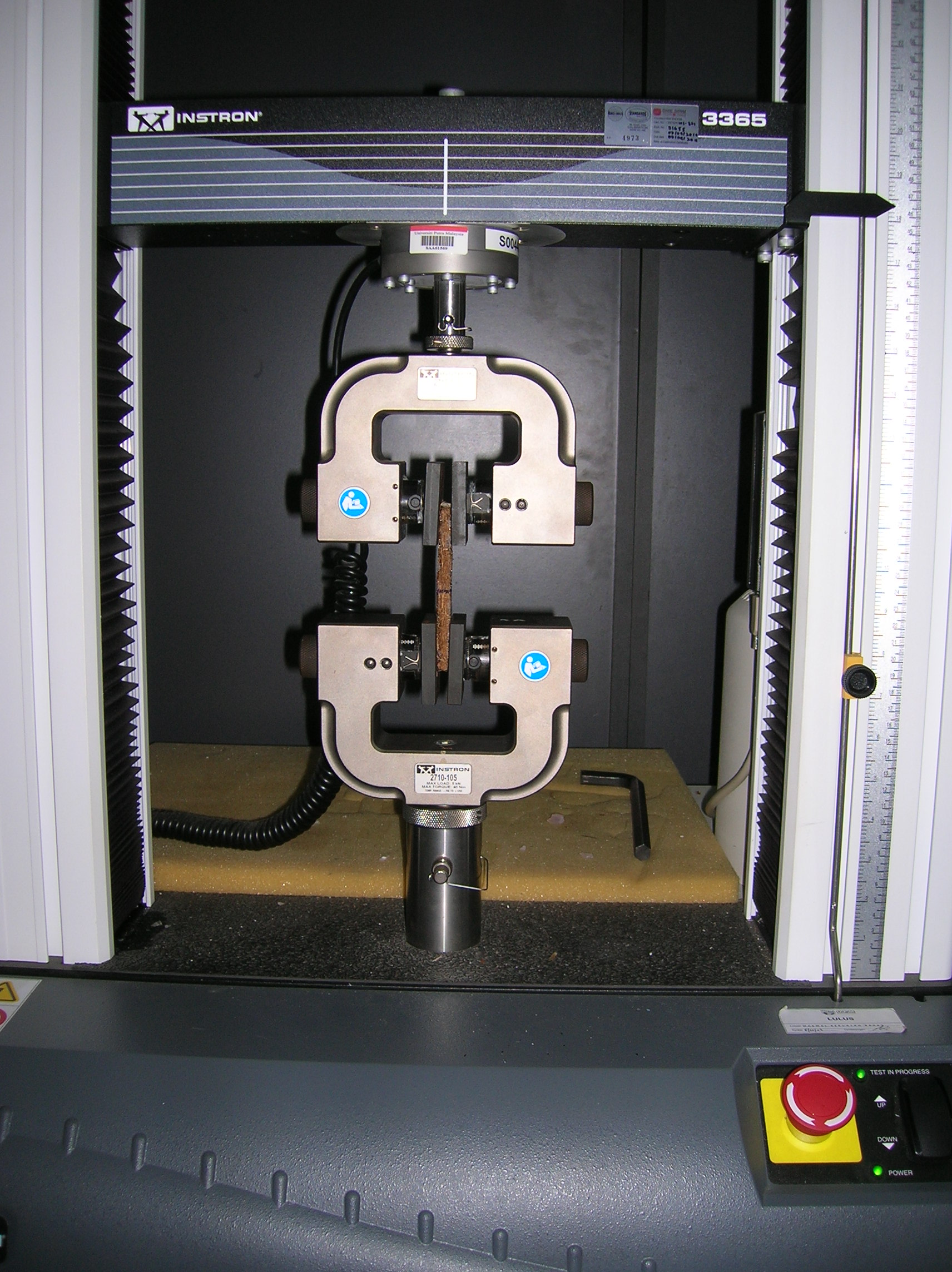

The tensile tester is a device that applies a controlled tensile force to a specimen of material. The specimen is typically held in place by grips, and the force is applied by a motor. The tester measures the force applied to the specimen and the resulting elongation. This data can then be used to calculate the material’s tensile strength, modulus of elasticity, and other mechanical properties.

Tensile testers are used in a wide variety of industries, including aerospace, automotive, and construction. They are used to test the strength of materials used in everything from aircraft wings to car bodies to bridges. Tensile testing is also used in research and development to develop new materials with improved mechanical properties.

## 2. Tensile Tester: Quantifying Material Elasticity And Strength’s History and Myth

The history of tensile testing can be traced back to the early days of engineering. The first tensile tester was invented in the early 1800s by a French engineer named Louis Vicat. Vicat’s tester was a simple device that used a lever to apply a force to a specimen of material. He used this tester to study the strength of different types of building materials.

Tensile testing has come a long way since Vicat’s time. Modern tensile testers are much more sophisticated and accurate than the early models. They are also capable of testing a wider range of materials. However, the basic principles of tensile testing remain the same. Tensile testers are used to apply a controlled force to a specimen of material and measure the resulting elongation. This data can then be used to calculate the material’s tensile strength, modulus of elasticity, and other mechanical properties.

## 2. Tensile Tester: Quantifying Material Elasticity And Strength’s Hidden Secret

Tensile testing is a valuable tool for engineers and designers. It provides them with the information they need to select the right materials for their applications. Tensile testing can also be used to develop new materials with improved mechanical properties.

Here are some of the hidden secrets of tensile testing:

- Tensile testing can be used to identify the weakest link in a material. This information can be used to improve the design of the material or to develop new materials that are more resistant to failure.

- Tensile testing can be used to predict the behavior of a material under real-world conditions. This information can be used to ensure that the material will perform as expected in the field.

- Tensile testing can be used to troubleshoot problems with materials. If a material is not performing as expected, tensile testing can be used to identify the cause of the problem.

## 2. Tensile Tester: Quantifying Material Elasticity And Strength’s Recommendation

If you are involved in the design, development, or testing of materials, then you should consider using a tensile tester. Tensile testing is a valuable tool that can provide you with the information you need to make informed decisions about the materials you use.

Here are some tips for choosing the right tensile tester for your needs:

- Consider the types of materials you will be testing. Some tensile testers are designed to test specific types of materials, such as metals, plastics, or composites.

- Consider the capacity of the tensile tester. The capacity of a tensile tester is the maximum force that it can apply to a specimen. Make sure that the tensile tester you choose has a capacity that is sufficient for the materials you will be testing.

- Consider the accuracy of the tensile tester. The accuracy of a tensile tester is the degree to which it can measure the force applied to a specimen and the resulting elongation. Make sure that the tensile tester you choose has an accuracy that is sufficient for your needs.

### 2. Tensile Tester: Quantifying Material Elasticity And Strength and Related Keywords

The following are some related keywords for 2. Tensile Tester: Quantifying Material Elasticity And Strength:

- Tensile strength

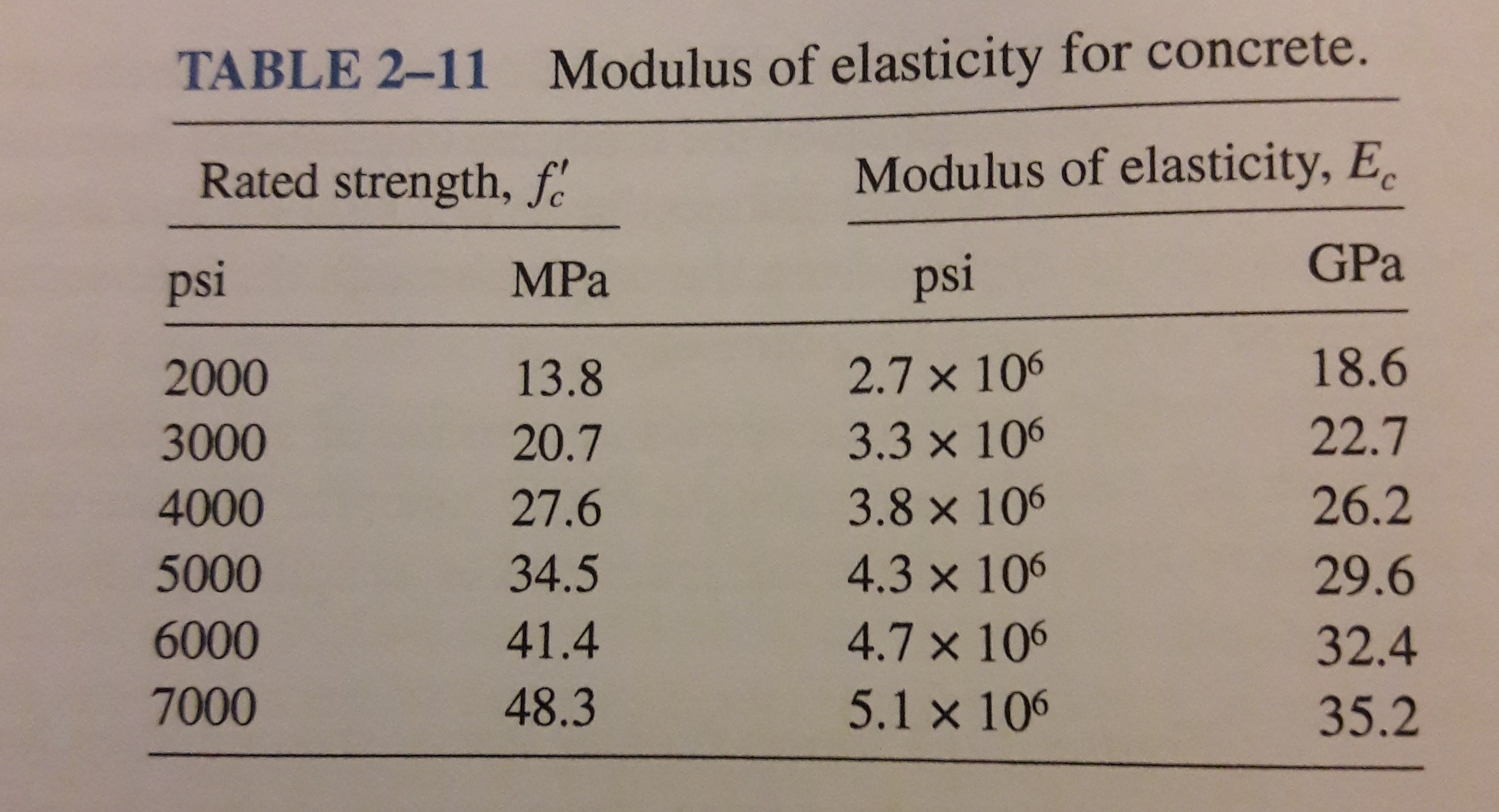

- Modulus of elasticity

- Yield strength

- Elongation at break

- Stress-strain curve

- Material testing

- Mechanical properties

- Engineering materials

2. Tensile Tester: Quantifying Material Elasticity And Strength Tips

Here are some tips for getting the most out of your tensile tester:

- Make sure that the specimen is properly aligned in the grips. If the specimen is not aligned properly, it can affect the accuracy of the test.

- Use the correct grip pressure. The grip pressure should be sufficient to hold the specimen in place without damaging it.

- Apply the force to the specimen at a constant rate. The rate at which the force is applied can affect the results of the test.

- Record the force and elongation data accurately. The force and elongation data can be used to calculate the material’s tensile strength, modulus of elasticity, and other mechanical properties.

2. Tensile Tester: Quantifying Material Elasticity And Strength

Tensile testing is a valuable tool for engineers and designers. It provides them with the information they need to select the right materials for their applications. Tensile testing can also be used to develop new materials with improved mechanical properties.

2. Tensile Tester: Quantifying Material Elasticity And Strength Fun Facts

Here are some fun facts about tensile testing:

- The first tensile tester was invented in the early 1800s by a French engineer named Louis Vicat.

- Tensile testing is used to test the strength of materials used in everything from aircraft wings to car bodies to bridges.

- Tensile testing can be used to identify the weakest link in a material.

- Tensile testing can be used to predict the behavior of a material under real-world conditions.

- Tensile testing can be used to troubleshoot problems with materials.

2. Tensile Tester: Quantifying Material Elasticity And Strength How To

Here are some tips on how to use a tensile tester:

- Make sure that the specimen is properly aligned in the grips.

- Use the correct grip pressure.

- Apply the force to the specimen at a constant rate.

- Record the force and elongation data accurately.

2. Tensile Tester: Quantifying Material Elasticity And Strength What If

What if you could use a tensile tester to test the strength of your own materials?

You can! Here is a simple experiment that you can do to test the strength of different materials:

- Gather a variety of materials, such as paper, plastic, metal, and rubber.

- Cut each material into a strip that is about 1 inch wide and 10 inches long.

- Attach one end of each strip to a fixed object.

- Attach the other end of each strip to a weight.

- Gradually increase the weight until the strip breaks.

- Record the weight at which each strip breaks.

2. Tensile Tester: Quantifying Material Elasticity And Strength Listicle

Here is a listicle of 10 things you can do with a tensile tester:

- Test the strength of different materials.

- Identify the weakest link in a material.

- Predict the behavior of a material under real-world conditions.

- Troubleshoot problems with