Measuring Tensile Strength: Unveiling Material Properties with Tensile Force Indicators

Material testing plays a crucial role in ensuring the safety and quality of products we use daily. Tensile force indicators are indispensable tools in this process, enabling precise quantification of the forces applied to materials under tension. By measuring tensile strength, engineers and scientists gain invaluable insights into the behavior and integrity of materials.

Target of Tensile Force Indicators: Precision and Accuracy in Material Testing

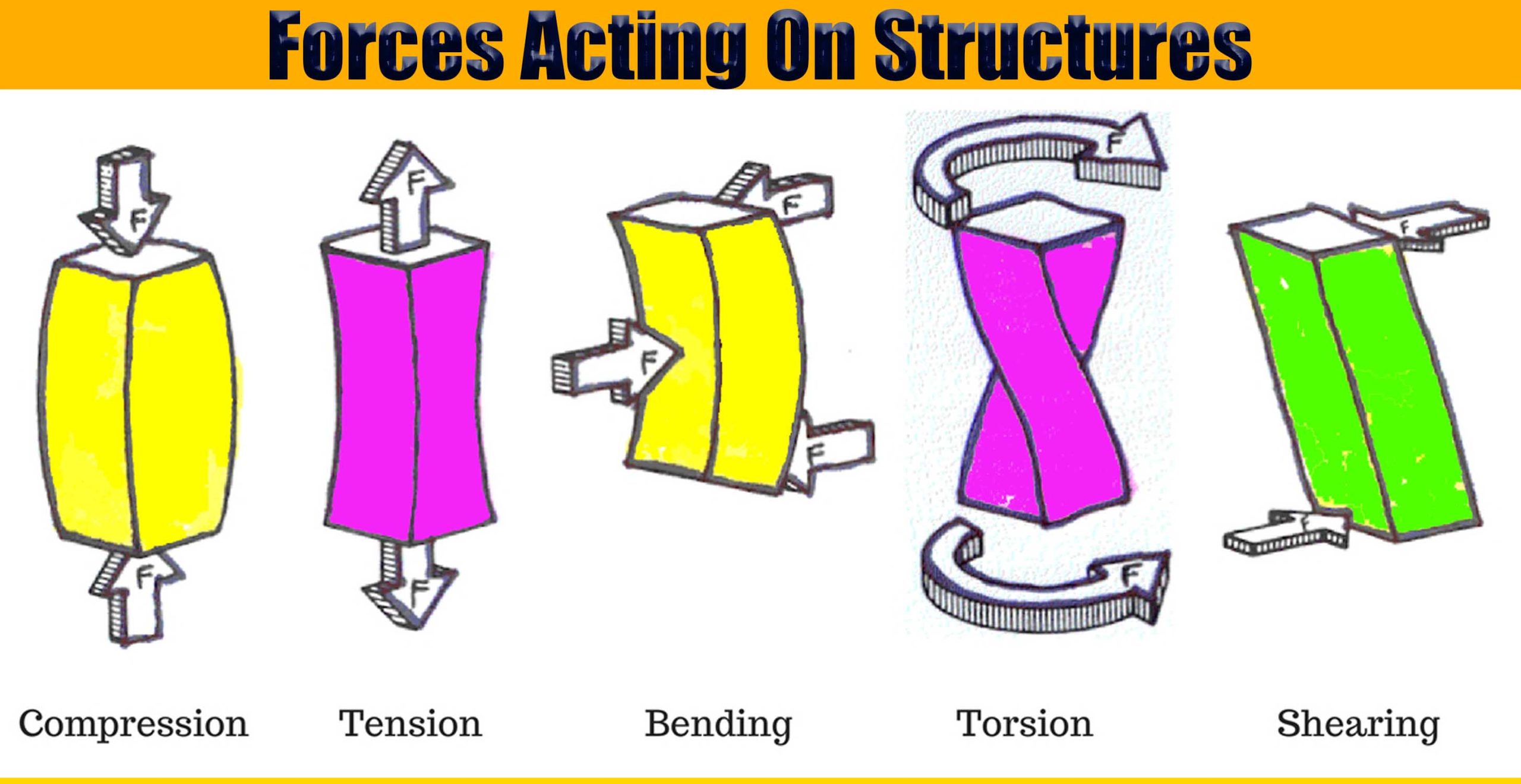

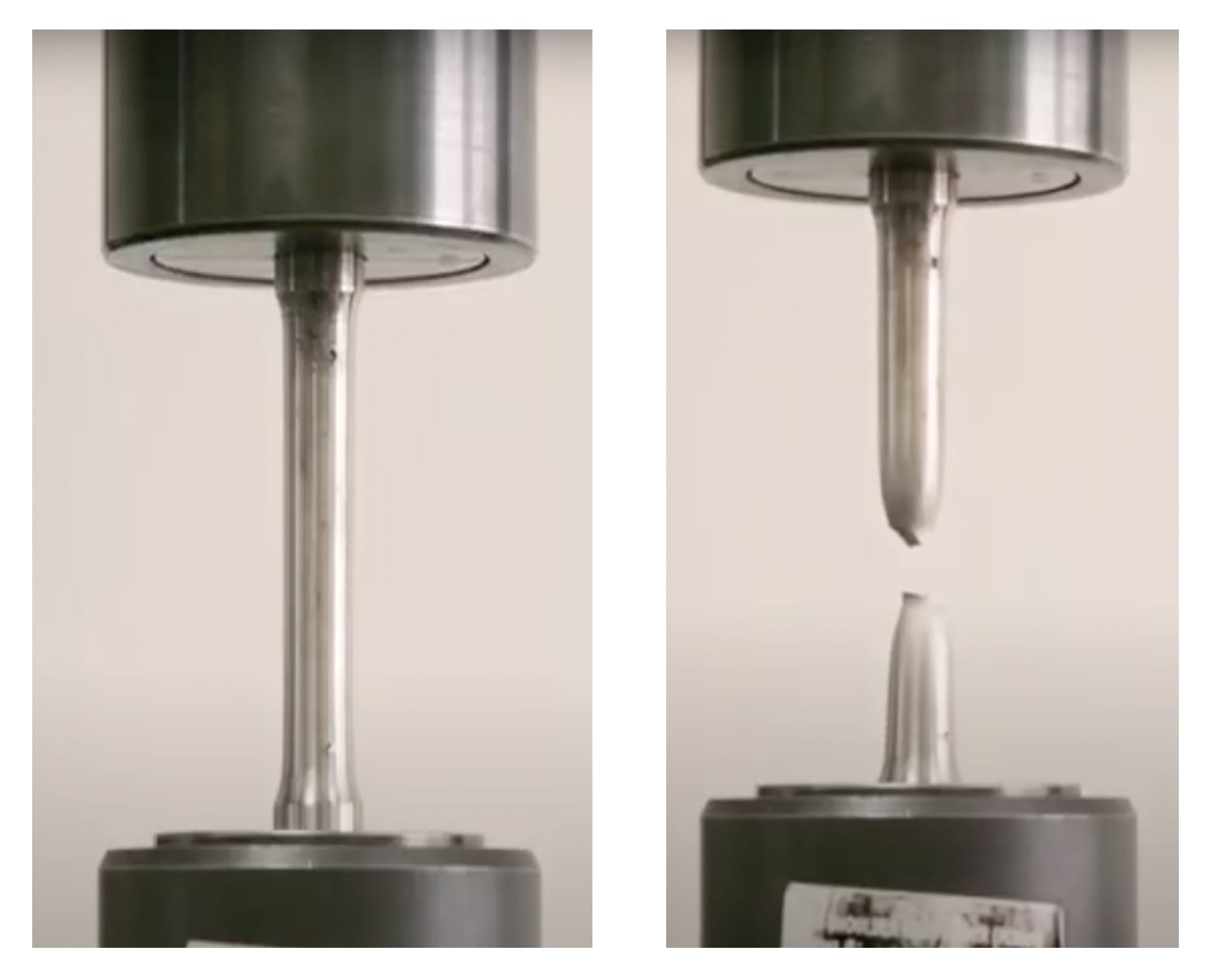

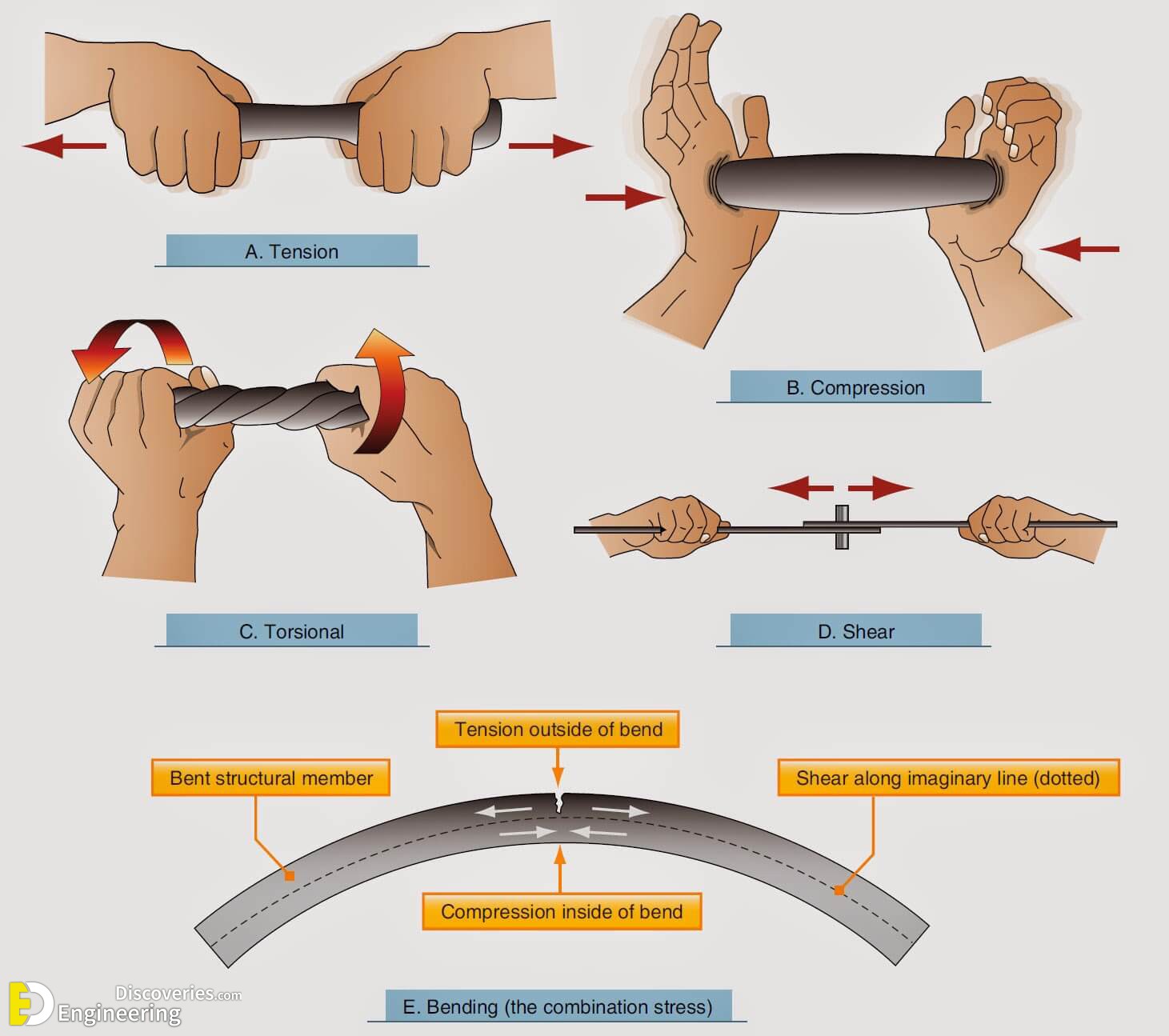

Tensile force indicators are designed to accurately measure the force required to pull a material apart until it breaks. This data is essential for evaluating the tensile strength of materials, which is a key indicator of their resistance to stretching. Understanding tensile strength helps manufacturers optimize material selection, design, and production processes to ensure product reliability and durability.

The Mechanics of Tensile Force Indicators: Unraveling the Science

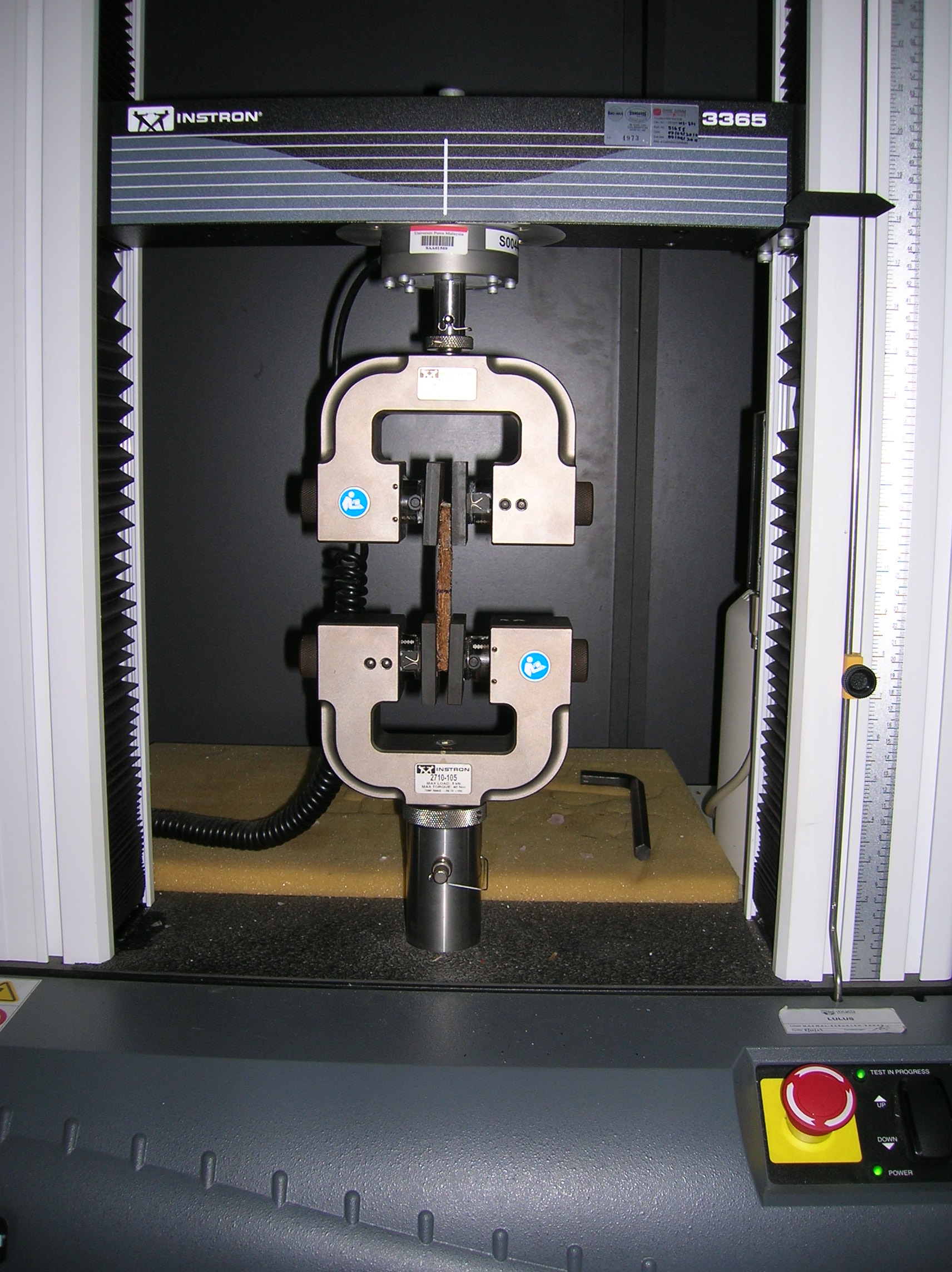

Tensile force indicators employ various mechanisms to measure the force applied to materials. Strain gauges, load cells, and extensometers are commonly used. These sensors convert mechanical forces into electrical signals that can be processed and displayed by a digital indicator. The accuracy and reliability of tensile force indicators are critical for obtaining precise measurements.

History and Evolution of Tensile Force Indicators: A Journey of Innovation

The history of tensile force indicators is intertwined with the development of material testing techniques. From early mechanical devices to modern digital instruments, tensile force indicators have undergone significant advancements. The evolution of these tools has paralleled the growing demands for accurate and efficient material characterization.

Unveiling the Secrets of Tensile Force Indicators: A Deeper Dive into Functionality

Tensile force indicators are more than just measuring devices. They provide valuable information about material behavior under tension. By analyzing force-elongation curves, researchers and engineers can determine material properties such as yield strength, elongation at break, and Young’s modulus. These insights are crucial for understanding the limits and capabilities of materials in various applications.

Applications of Tensile Force Indicators: Diverse Industries, Countless Benefits

Tensile force indicators find applications in a wide range of industries, including automotive, aerospace, construction, and medical. They are used to test materials such as metals, plastics, composites, and textiles. By understanding the tensile strength and other mechanical properties of materials, manufacturers can optimize product design, improve safety, and ensure the reliability of their products.

Tips for Effective Tensile Force Measurement: Maximizing Precision and Accuracy

Accurate tensile force measurements require careful attention to several factors. Proper specimen preparation, alignment, and test conditions are essential. Using calibrated equipment and following standardized testing procedures ensures reliable and repeatable results.

Influencing Factors in Tensile Force Measurement: Unraveling the Complexities

The results of tensile force measurements can be influenced by various factors, including specimen geometry, strain rate, temperature, and environmental conditions. Understanding these factors and controlling them during testing is crucial for obtaining accurate and meaningful data.

Fun Facts about Tensile Force Indicators: Uncovering the Unconventional

Beyond their scientific applications, tensile force indicators have a few intriguing fun facts. They have been used in experiments to measure the strength of spider silk and the tensile properties of human hair. These unusual demonstrations highlight the versatility and relevance of tensile force indicators in understanding the world around us.

How to Use Tensile Force Indicators: A Step-by-Step Guide

Using tensile force indicators involves a straightforward process. Prepare the specimen, mount it in the testing machine, and set the appropriate test parameters. Calibrate the equipment and start the test. Monitor the force-elongation curve and record the desired data. By following these steps, users can obtain accurate and reliable tensile strength measurements.

What if Tensile Force Indicators Fail: Understanding the Consequences

Malfunctioning tensile force indicators can lead to inaccurate or misleading results. Broken sensors, calibration issues, or improper specimen preparation can compromise the integrity of the measurements. It is crucial to regularly calibrate and maintain tensile force indicators to ensure their accuracy and reliability.

Listicle of 5 Key Points about Tensile Force Indicators: A Quick Summary

1. Tensile force indicators measure the force required to pull a material apart.

2. They provide accurate and reliable data on tensile strength and other mechanical properties.

3. Tensile force indicators are used in various industries for material testing.

4. Proper specimen preparation and test conditions are crucial for accurate measurements.

5. Calibration and maintenance ensure the reliability of tensile force indicators.

Question and Answer Section about Tensile Force Indicators: Addressing Common Queries

Q: What is the difference between tensile strength and yield strength?

A: Tensile strength is the maximum force per unit area that a material can withstand before breaking. Yield strength is the point at which a material begins to deform permanently.

Q: How can I improve the accuracy of my tensile force measurements?

A: Calibrating the equipment, preparing the specimen properly, and following standardized testing procedures can enhance measurement accuracy.

Q: What materials can be tested using tensile force indicators?

A: Tensile force indicators can test a wide range of materials, including metals, plastics, composites, and textiles.

Q: What safety precautions should I take when using tensile force indicators?

A: Always wear appropriate safety gear, secure the specimen properly, and follow the manufacturer’s instructions to avoid potential hazards.

Conclusion of 5. Tensile Force Indicator: Quantifying Tensile Forces For Material Testing

Tensile force indicators are indispensable tools in material testing, providing precise quantification of the forces applied to materials under tension. Their accuracy and reliability ensure the integrity of material characterization, contributing to the safety and quality of products we use daily. Understanding the principles, applications, and limitations of tensile force indicators empowers engineers and scientists to make informed decisions about material selection and design.