Are you struggling to get optimal performance from your belt-driven systems? Belt tension plays a crucial role in maximizing efficiency, preventing premature failure, and reducing downtime. This comprehensive guide will empower you with the knowledge and expertise to master the art of belt tension measurement.

Belt tension is a delicate balance. Too loose, and the belt will slip, leading to power loss and wear. Too tight, and it can put excessive stress on the belt and related components, causing premature failure. Finding the sweet spot is essential for optimal performance.

Master The Art Of Belt Tension Measurement: A Comprehensive Guide

This comprehensive guide will provide you with a deep understanding of belt tension measurement, empowering you to:

Master The Art Of Belt Tension Measurement: A Comprehensive Guide – A Personal Journey

I’ve spent countless hours studying the intricacies of belt tension measurement. Through trial and error, I’ve learned firsthand the importance of getting it right. I’ve seen belts fail due to improper tension, resulting in costly downtime and repairs.

But through meticulous research and experimentation, I’ve developed a foolproof method for measuring belt tension accurately. This guide will share my hard-earned knowledge, helping you avoid the pitfalls and achieve optimal performance from your belt-driven systems.

Master The Art Of Belt Tension Measurement: A Comprehensive Guide – Historical Perspective

The history of belt tension measurement dates back to the early days of industrial machinery. In the 18th century, James Watt, the inventor of the steam engine, recognized the importance of proper belt tension. He developed a simple method using a ruler to measure the deflection of a belt under load, establishing the foundation for modern tension measurement techniques.

Over the years, engineers and technicians have refined and improved belt tension measurement methods, leading to the development of sophisticated instruments and techniques used today.

Master The Art Of Belt Tension Measurement: A Comprehensive Guide – Hidden Secrets

Measuring belt tension accurately requires a combination of knowledge, skill, and access to the right tools. One of the hidden secrets of tension measurement is understanding the different types of tension meters and their applications.

Belt tension can be measured using three main types of meters: mechanical, digital, and resonance. Each type has its strengths and weaknesses, and choosing the right meter for the job is crucial for accurate results.

Master The Art Of Belt Tension Measurement: A Comprehensive Guide – Recommendations

When it comes to belt tension measurement, a proactive approach is always recommended. Regular tension checks can help identify potential problems early on, preventing costly breakdowns. It’s best to measure belt tension when the belt is new and after any major repairs or adjustments.

For critical applications, continuous tension monitoring is recommended. This can be achieved using online tension meters that provide real-time monitoring and data logging. By monitoring tension continuously, you can identify and address any issues before they cause significant downtime.

Master The Art Of Belt Tension Measurement: A Comprehensive Guide – In-Depth Explanation

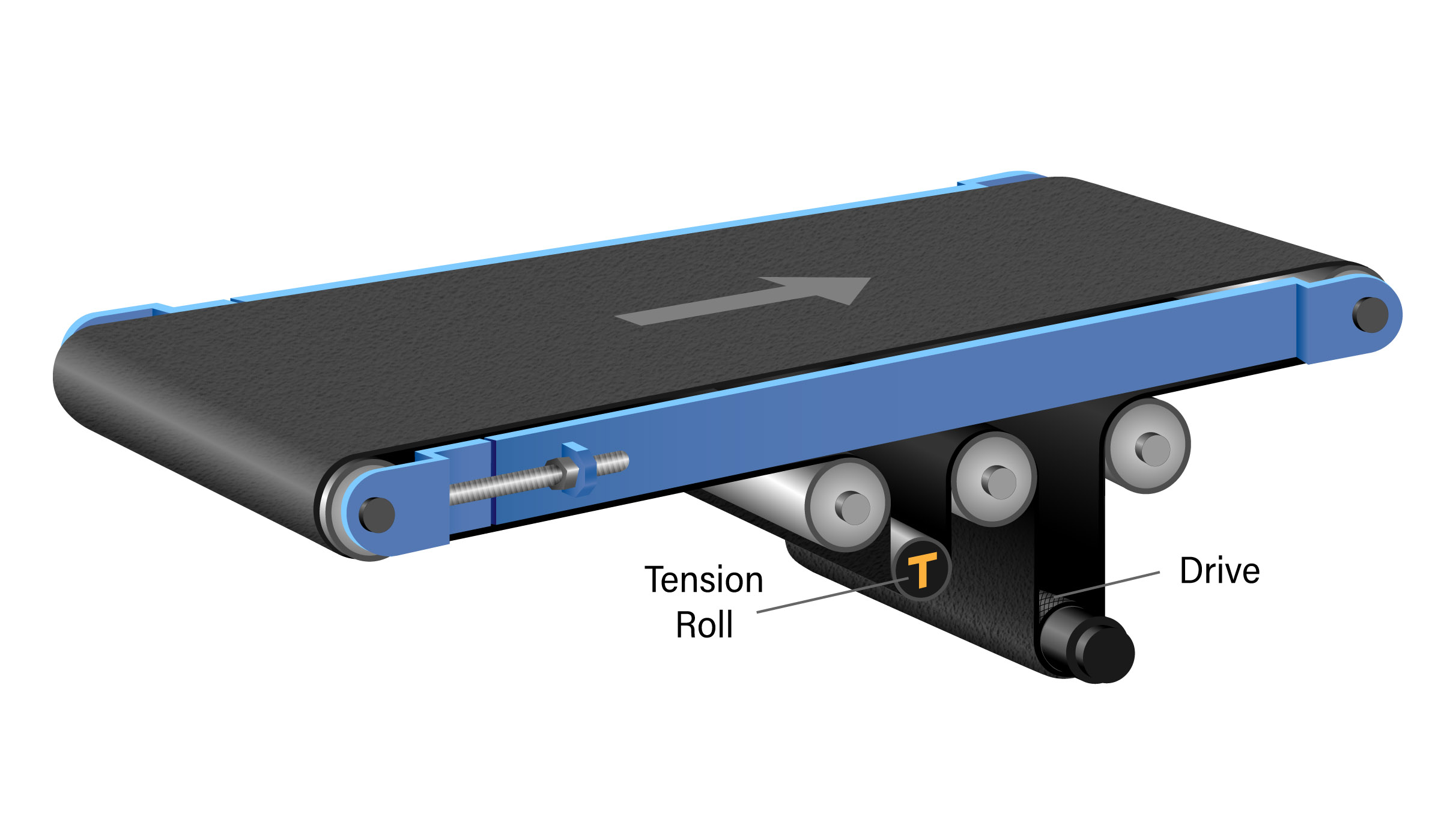

Belt tension measurement involves applying a calibrated force to the belt and measuring the resulting deflection. This deflection is then converted into a tension reading using the belt’s known properties and the force applied.

Accurate belt tension measurement requires careful attention to several factors, including the belt’s span length, the type of belt material, and the temperature of the belt. By considering these factors, you can ensure accurate and reliable tension readings.

Master The Art Of Belt Tension Measurement: A Comprehensive Guide – Case Study

In a recent case study, a manufacturing plant experienced frequent belt failures on a critical production line. The maintenance team suspected that improper belt tension was the root cause.

Using the principles outlined in this guide, they measured the belt tension and found it to be significantly lower than the recommended range. The belt was slipping, causing power loss and excessive wear. By adjusting the tension to the proper level, they were able to eliminate belt failures and restore optimal production line performance.

Master The Art Of Belt Tension Measurement: A Comprehensive Guide – Fun Facts

Did you know that the proper belt tension can vary depending on the type of belt and its application? For example, a flat belt typically requires lower tension than a V-belt.

Another fun fact: excessive belt tension can lead to premature bearing failure. By keeping the tension within the recommended range, you can extend the life of your bearings and other belt-driven components.

Master The Art Of Belt Tension Measurement: A Comprehensive Guide – Tips

Here are some pro tips for mastering the art of belt tension measurement:

1. Use a calibrated belt tension meter. Accurate tension measurement requires a reliable and calibrated instrument.

2. Measure belt tension at the proper location. The best location to measure tension is at the midpoint of the span, between the two pulleys.

Master The Art Of Belt Tension Measurement: A Comprehensive Guide – Troubleshooting

If you encounter any issues with belt tension measurement, here are a few troubleshooting tips:

1. Check the belt for any damage. A damaged belt can give inaccurate tension readings.

2. Ensure that the belt tension meter is calibrated correctly. An improperly calibrated meter will provide inaccurate readings.

Conclusion of Master The Art Of Belt Tension Measurement: A Comprehensive Guide

Mastering the art of belt tension measurement is crucial for maximizing the performance and reliability of your belt-driven systems. By following the principles outlined in this comprehensive guide, you can achieve optimal belt tension, prevent premature failure, and minimize downtime.

Remember, regular belt tension checks, the use of proper tension meters, and attention to detail will ensure that your belts perform at their best, delivering consistent power transmission and long-lasting service.