V-Belt Alignment Guide: Optimize Performance and Minimize Wear with Precision Accuracy

Accurate V-belt alignment is crucial for achieving optimal performance and minimizing wear. Misalignment leads to premature failure, reduced efficiency, and increased maintenance costs. Follow this guide to align V-belts precisely, ensuring peak performance and longevity.

Misaligned V-belts experience excessive wear and strain, leading to premature failure. They can slip, generate excessive heat, and cause vibrations, compromising efficiency and reliability.

Precise V-belt alignment optimizes power transmission, prevents premature wear, and extends the lifespan of belts and pulleys. Proper alignment ensures that belts run smoothly and efficiently, minimizing friction and reducing maintenance costs.

V-Belt Alignment Guide: Optimize Performance and Minimize Wear with Precision Accuracy

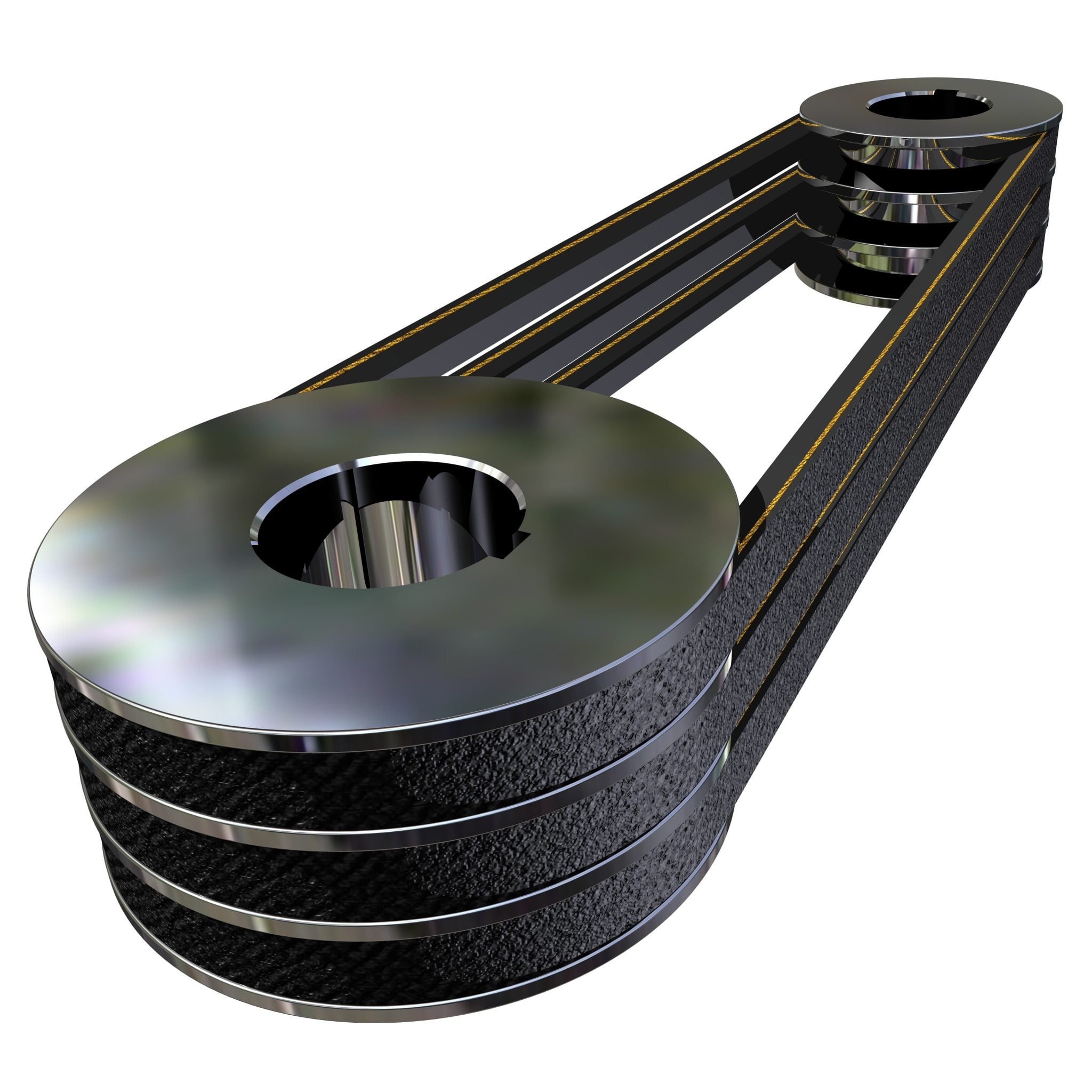

What is V-Belt Alignment?

V-belt alignment refers to the precise positioning of V-belts on pulleys to ensure optimal performance and minimize wear. Proper alignment ensures that belts run smoothly and evenly within the pulley grooves, transmitting power efficiently while minimizing friction and wear.

Misalignment occurs when belts are not positioned correctly on pulleys, causing them to run off-center or at an incorrect angle. This can lead to premature belt failure, reduced efficiency, and excessive wear on pulleys and bearings.

History and Myths of V-Belt Alignment

V-belt alignment has been practiced for decades in various industries. Over time, several myths and misconceptions have emerged around this topic, including:

- Myth: V-belts can be aligned by eye.

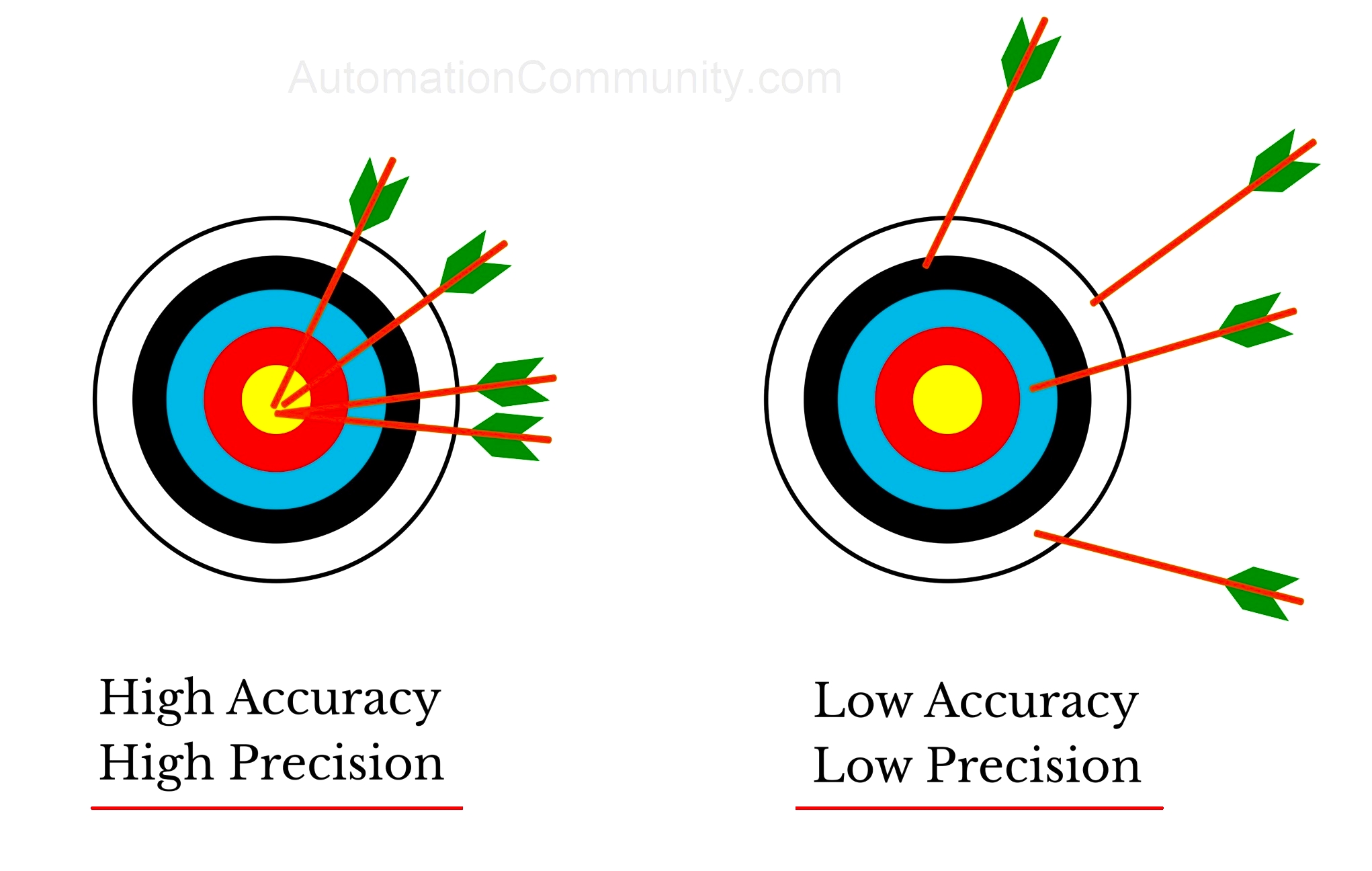

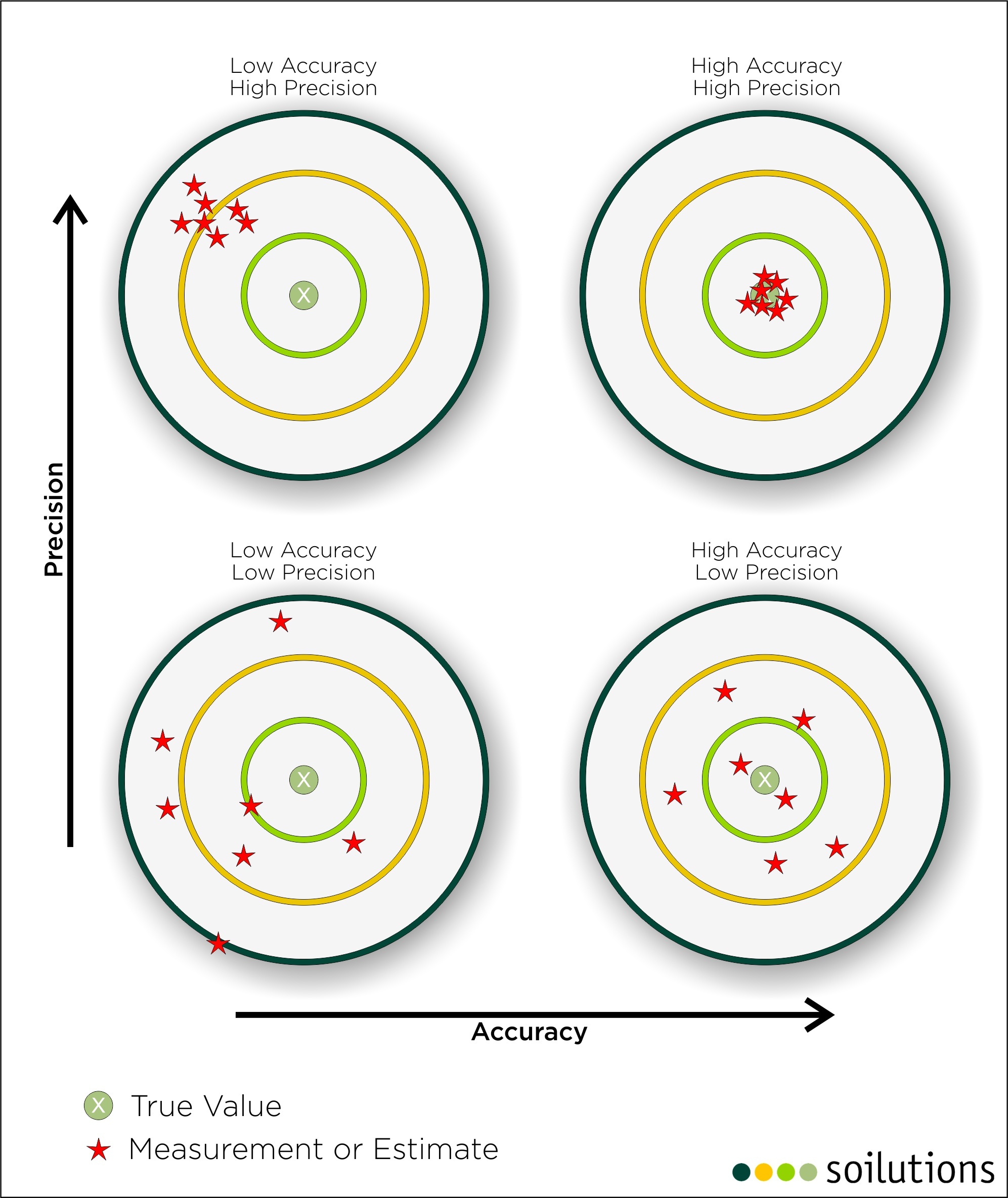

- Fact: Precise alignment requires the use of accurate measurement tools.

- Myth: V-belts need to be extremely tight to prevent slippage.

- Fact: Over-tightening V-belts can lead to premature belt failure and bearing damage.

Hidden Secrets of V-Belt Alignment

Achieving precise V-belt alignment requires attention to several key factors, often overlooked or misunderstood.

- Pulley Alignment: Pulleys should be aligned parallel to each other and perpendicular to the belt path.

- Belt Tension: V-belts should be tensioned correctly to prevent slippage and excessive wear.

- Belt Condition: Regularly inspect belts for signs of wear, damage, or stretching.

Recommendations for V-Belt Alignment

Follow these recommendations for optimal V-belt alignment:

- Use a straightedge or laser alignment tool to align pulleys.

- Check belt tension using a belt tension gauge or by measuring deflection.

- Replace worn or damaged belts promptly.

- Regularly monitor and adjust alignment as needed.

V-Belt Alignment Tools and Techniques

Various tools and techniques can assist in achieving precise V-belt alignment.

- Straightedge: A straightedge can be used to check pulley alignment.

- Laser Alignment Tool: A laser alignment tool projects a laser line to accurately align pulleys.

- Belt Tension Gauge: A belt tension gauge measures belt tension to ensure proper tightness.

Tips for V-Belt Alignment

Follow these tips for successful V-belt alignment:

- Inspect belts and pulleys regularly.

- Use proper alignment tools and techniques.

- Train maintenance personnel on alignment procedures.

- Monitor alignment over time and make adjustments as needed.

V-Belt Alignment: Troubleshooting

Common V-belt alignment issues can be identified and resolved through troubleshooting.

- Belt Squealing: Misalignment or excessive tension.

- Belt Slippage: Insufficient tension or misalignment.

- Premature Belt Failure: Misalignment, over-tightening, or belt damage.

Fun Facts about V-Belt Alignment

Here are some interesting facts about V-belt alignment:

- V-belts were invented in the 19th century.

- Proper alignment can increase belt lifespan by up to 50%.

- Misalignment can cause up to 20% power loss.

How to Align V-Belts

Follow these steps to align V-belts:

- Prepare: Gather necessary tools and safety gear.

- Inspect: Check belts and pulleys for damage or wear.

- Align Pulleys: Use a straightedge or laser alignment tool to align pulleys.

- Tension Belts: Adjust belt tension using a belt tension gauge or by measuring deflection.

- Check Alignment: Re-check alignment after tensioning belts.

What if V-Belts Are Not Aligned?

Misaligned V-belts can cause several problems, including:

- Premature belt failure.

- Reduced efficiency.

- Increased maintenance costs.

- Noise and vibration.

Listicle: Benefits of V-Belt Alignment

Here are the key benefits of proper V-belt alignment:

- Increased belt lifespan.

- Improved efficiency.

- Reduced maintenance costs.

- Reduced noise and vibration.

- Improved safety.

Conclusion of V-Belt Alignment Guide

Precise V-belt alignment is essential for optimizing performance, minimizing wear, and extending the lifespan of belts and pulleys. By following the principles outlined in this guide, you can achieve accurate alignment, ensuring efficient power transmission and reliable operation.