Struggling to keep your equipment and machinery running smoothly? Understanding the difference between maintenance and repair can be the key to extending the life of your assets and saving money in the long run. Let’s dive into the specifics and explore the distinctions between these two crucial aspects of asset management.

Pain Points in Asset Management

Unexpected breakdowns, costly repairs, and reduced equipment lifespan are just a few of the common challenges faced by many organizations. These issues not only impact productivity but also strain budgets and put a damper on business operations.

The solution to these pain points lies in a comprehensive understanding of the difference between maintenance and repair. By distinguishing between proactive maintenance and reactive repairs, we can effectively prevent breakdowns, minimize downtime, and maximize the life of our equipment.

Difference Between Maintenance and Repair

Simply put, maintenance refers to proactive measures taken to prevent equipment failures and ensure optimal performance. Regular inspections, cleaning, lubrication, and adjustments fall under the umbrella of maintenance and help keep equipment running smoothly.

Repair, on the other hand, involves addressing specific issues or failures that have already occurred. It encompasses troubleshooting, component replacement, and other actions necessary to restore equipment to proper working condition.

Types of Maintenance

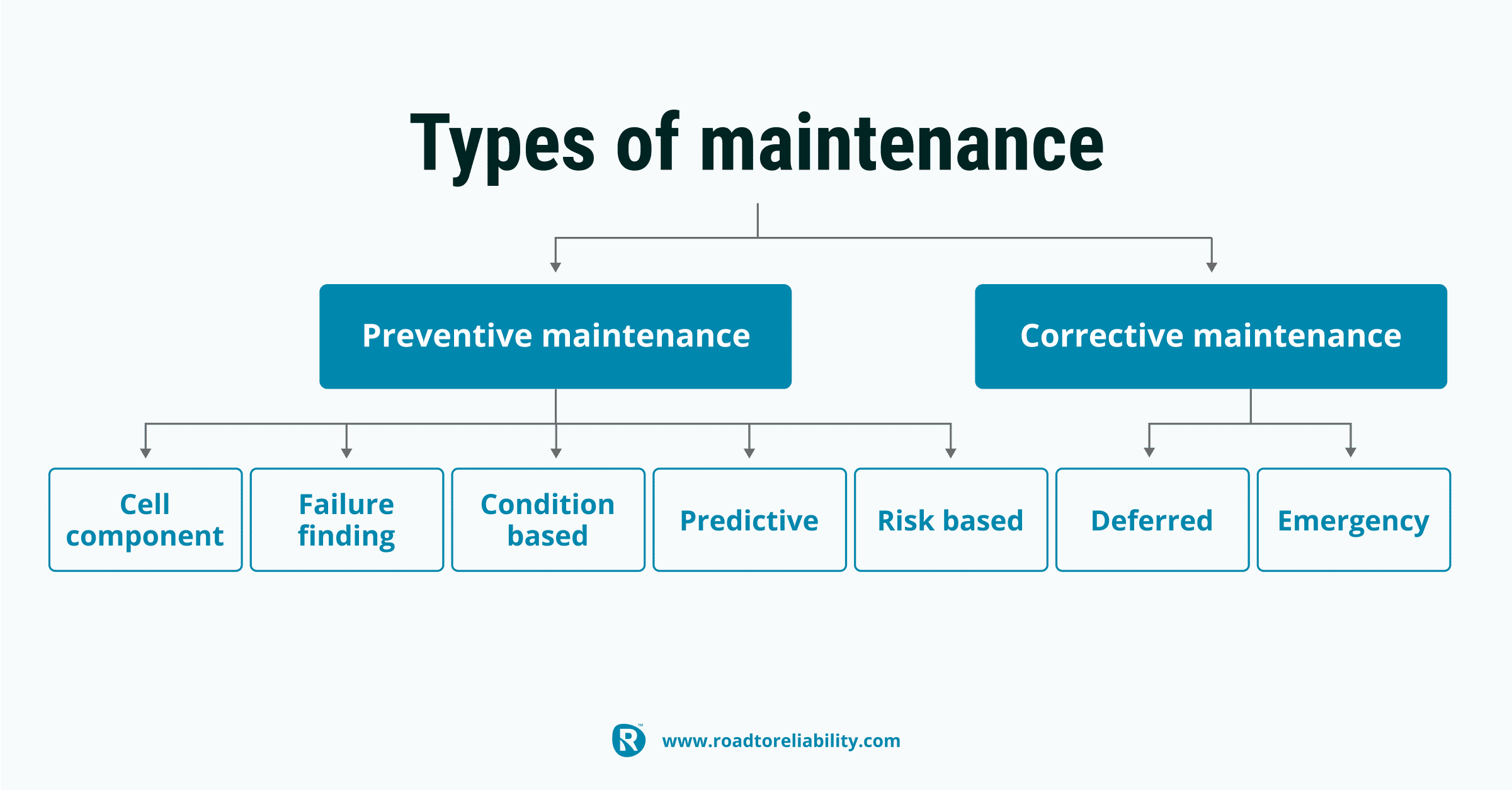

Maintenance itself can be divided into various categories, including:

- Preventive maintenance: Routine inspections and upkeep to prevent potential problems.

- Predictive maintenance: Using monitoring technologies to identify potential issues before they become major failures.

- Condition-based maintenance: Scheduling maintenance based on the actual condition of the equipment, as indicated by sensors or analytics.

Benefits of Maintenance

Implementing a proactive maintenance program offers numerous benefits for organizations, including:

- Increased equipment life span

- Reduced downtime and unexpected failures

- Improved safety and regulatory compliance

- Lower long-term repair costs

- Increased productivity and efficiency

Maintenance vs. Repair in Practice

Imagine a factory with production machinery. Proactive maintenance involves regular inspections of the machinery to identify potential issues. By addressing minor problems early on, such as replacing worn belts or tightening loose bolts, costly repairs and major breakdowns can be prevented.

In contrast, repair work becomes necessary when a machine breaks down unexpectedly. This can result in significant downtime, lost production, and expensive repairs. In this case, the focus is on troubleshooting the problem and replacing or repairing damaged components to restore functionality.

History and Myths of Maintenance

The concept of maintenance has evolved over time. In the early days of industrialization, a reactive approach to repair was common. However, as technology advanced and equipment became more sophisticated, the need for a proactive approach to maintenance emerged.

One myth surrounding maintenance is that it is only necessary for large-scale industrial operations. However, the principles of maintenance apply to all types of equipment, regardless of size or industry.

Hidden Secrets of Maintenance

Effective maintenance is not merely about following checklists and schedules. It involves understanding the equipment, identifying potential failure points, and implementing customized maintenance strategies.

By analyzing equipment data and leveraging predictive technologies, maintenance teams can uncover hidden patterns and trends that indicate potential issues. This enables them to proactively address these issues before they escalate into major problems.

Recommendations for Effective Maintenance

To ensure effective maintenance, consider the following recommendations:

- Develop a comprehensive maintenance plan tailored to your equipment.

- Establish clear maintenance schedules and responsibilities.

- Invest in training and upskilling maintenance personnel.

- Monitor equipment performance and utilize data analysis tools.

- Create a culture of continuous improvement and innovation in maintenance

Maintenance Engineering

Maintenance engineering plays a critical role in developing and implementing maintenance strategies. It involves applying engineering principles to optimize maintenance processes, improve equipment reliability, and reduce downtime.

Maintenance engineers use techniques such as failure analysis, reliability engineering, and condition monitoring to identify and address potential issues before they become major problems.

Maintenance Management

Maintenance management encompasses the planning, scheduling, and coordination of maintenance activities. It involves managing maintenance teams, setting priorities, and ensuring that maintenance is performed efficiently and effectively.

Effective maintenance management requires strong communication and collaboration between different departments, including operations, engineering, and finance.

Fun Facts About Maintenance

Here are some fun facts about maintenance:

- The Great Wall of China was built using a form of maintenance called “repointing.” This involved periodically filling in cracks and gaps with new mortar.

- The world’s oldest known maintenance manual dates back to ancient Egypt and contains instructions on maintaining chariots.

- The term “maintenance” originated from the French word “maintenir,” which means “to hold in place.”

How to Implement Maintenance

Implementing a maintenance program requires the following steps:

- Conduct an assessment of your equipment and maintenance needs.

- Develop a maintenance plan that outlines schedules, tasks, and responsibilities.

- Train maintenance personnel on proper maintenance procedures.

- Monitor equipment performance and make adjustments to the maintenance plan as necessary.

- Continuously evaluate and improve the maintenance program to optimize its effectiveness.

What if You Don’t Maintain Your Equipment?

Failure to maintain equipment can have severe consequences, including:

- Increased risk of equipment failure and downtime

- Lowered productivity and efficiency

- Higher repair costs

- Reduced equipment life span

- Safety hazards

Listicle of Maintenance Benefits

Here is a listicle of the benefits of maintenance:

- Increased equipment life span

- Reduced downtime and unexpected failures

- Improved safety and regulatory compliance

- Lower long-term repair costs

- Increased productivity and efficiency

- Improved employee morale

- Reduced environmental impact

- Enhanced brand reputation

- Increased property value

- Peace of mind

Question and Answer

Q1: What is the difference between maintenance and repair?

A1: Maintenance refers to proactive measures to prevent equipment failures, while repair involves addressing specific issues or failures that have already occurred.

Q2: Why is maintenance important?

A2: Maintenance helps increase equipment life span, reduce downtime, improve safety, lower repair costs, and increase productivity.

Q3: How can I implement a maintenance program?

A3: Start by assessing your equipment and maintenance needs, developing a maintenance plan, training personnel, monitoring equipment performance, and continuously evaluating and improving the program.

Q4: What are the risks of neglecting maintenance?

A4: Neglecting maintenance can lead to increased equipment failures, downtime, reduced productivity, higher repair costs, and safety hazards.

Conclusion of Difference Between Maintenance And Repair

Understanding the difference between maintenance and repair is essential for effective asset management. Maintenance measures are critical for preventing equipment failures and ensuring optimal performance, while repairs address specific issues that have already occurred.

By implementing a proactive maintenance program, organizations can maximize equipment life span, reduce downtime, improve safety, lower repair costs, and increase productivity. Regular inspections, predictive maintenance, and condition-based monitoring are key components of an effective maintenance strategy.