Your car’s engine is a complex machine, and it relies on a number of sensors to function properly. One of the most important sensors is the crank position sensor. This sensor tells the engine’s computer when the crankshaft is at the top of its stroke, which is essential for timing the ignition and fuel injection.

If the crank position sensor fails, it can cause a number of problems, including:

- Engine misfires

- Stalling

- Reduced power

- Increased fuel consumption

Crank Position Sensor Function and Its Role

The crank position sensor (CPS) is a critical component of an internal combustion engine. Its primary function is to detect the position of the crankshaft, specifically the top dead center (TDC) of each cylinder. This information is then transmitted to the engine’s electronic control unit (ECU), which uses it to calculate various engine parameters, such as ignition timing, fuel injection timing, and valve timing.

Accurate crankshaft position detection is essential for optimal engine performance, fuel efficiency, and emissions control. Without a functional CPS, the engine may experience misfires, rough idling, stalling, and reduced power output.

Components of Crank Position Sensor

The crank position sensor is typically a magnetic or optical device mounted near the crankshaft’s flywheel or harmonic balancer. It consists of the following components:

- Sensor element: Detects the presence or absence of a ferrous target (usually a gear or a notched wheel) attached to the crankshaft.

- Electronic circuitry: Amplifies and processes the sensor signal to generate a digital or analog output.

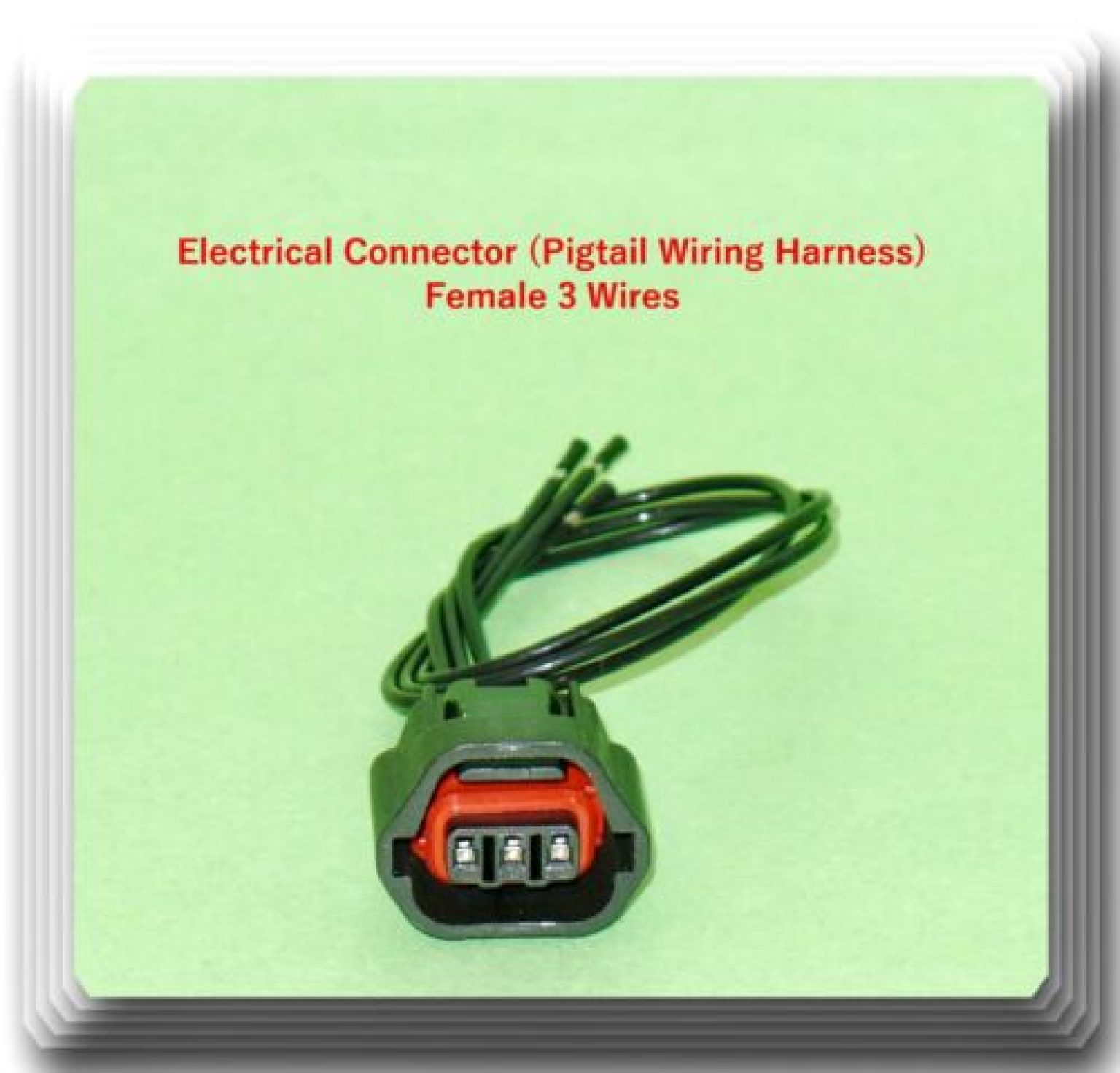

- Connector: Provides electrical connection between the sensor and the ECU.

Crank Position Sensor Failure and Diagnosis

Like any other electronic component, a crank position sensor can fail over time. Common symptoms of a faulty CPS include:

- Engine misfires

- Stalling

- Hard starting

- Reduced engine power

- Illuminated check engine light

Diagnosis of a failed CPS typically involves using a diagnostic scan tool to read fault codes from the ECU. Visual inspection of the sensor and its wiring harness can also be helpful in identifying any obvious damage or loose connections.

Conclusion of Crank Position Sensor Function

The crank position sensor plays a vital role in ensuring the proper functioning of an internal combustion engine. By accurately detecting the crankshaft position, it enables the ECU to precisely control ignition and fuel injection timing, resulting in optimal engine performance and efficiency.

Regular maintenance and prompt replacement of a faulty CPS can help prevent engine problems and ensure a smooth and reliable driving experience.