A crank position sensor is an essential part of a vehicle’s engine management system. It helps the engine run smoothly and efficiently by providing the engine control module (ECM) with information about the position of the crankshaft and the engine’s speed.

If your car is not running properly, one of the problems could be a faulty crank position sensor. Symptoms of a bad crank position sensor can include:

- Engine stalling or hesitation

- Difficulty starting the engine

- Decreased engine power

- Fuel economy problems

What Does a Crank Position Sensor Do?

The crank position sensor is responsible for detecting the position of the crankshaft. It does this by sending a signal to the ECM. The ECM uses this signal to determine the timing of the spark plugs and fuel injectors. The crank position sensor also helps the ECM to monitor the engine’s speed and to detect misfires.

Crank Position Sensor: Target

The target of a crank position sensor is a toothed wheel that is attached to the crankshaft. As the crankshaft rotates, the teeth on the wheel pass by the sensor. The sensor generates a signal that corresponds to the position of the teeth. The ECM uses this signal to determine the timing of the spark plugs and fuel injectors.

History and Myth of Crank Position Sensor

The crank position sensor was first used in the 1970s. Early crank position sensors used a magnetic pickup to generate a signal. However, these sensors were not very accurate. In the 1980s, Hall effect sensors were introduced. Hall effect sensors are more accurate and reliable than magnetic pickup sensors. Today, Hall effect sensors are the most common type of crank position sensor.

Hidden Secret of Crank Position Sensor

The crank position sensor is a critical component of the engine management system. Without a working crank position sensor, the engine will not run properly. If you are experiencing problems with your car’s engine, one of the first things you should check is the crank position sensor.

Recommendation of Crank Position Sensor

If you need to replace the crank position sensor on your car, it is important to choose a high-quality sensor. A good crank position sensor will be made from durable materials and will be accurate and reliable. You should also consider the cost of the sensor. Some crank position sensors can be expensive, but there are also more affordable options available.

Crank Position Sensor: Types and Functions

There are two main types of crank position sensors: inductive and Hall effect. Inductive sensors use a coil to generate a magnetic field. When the teeth on the target wheel pass by the sensor, the magnetic field is disrupted. This disruption creates a voltage signal that is sent to the ECM. Hall effect sensors use a semiconductor to generate a signal. When the teeth on the target wheel pass by the sensor, the semiconductor generates a voltage signal. The ECM uses this signal to determine the timing of the spark plugs and fuel injectors.

Tips of Crank Position Sensor

Here are some tips for getting the most out of your crank position sensor:

- Keep the sensor clean. Dirt and debris can interfere with the sensor’s ability to generate a signal.

- Check the sensor’s wires. Loose or damaged wires can prevent the sensor from sending a signal to the ECM.

- Replace the sensor if it is damaged. A damaged sensor will not be able to generate a signal, which will cause the engine to run poorly.

Crank Position Sensor: Troubleshooting

If you are experiencing problems with your car’s engine, one of the first things you should check is the crank position sensor. Here are some troubleshooting tips:

- Check the sensor’s signal. You can do this using a voltmeter. The signal should be a square wave with a frequency that corresponds to the engine’s speed.

- Check the sensor’s resistance. The resistance should be between 500 and 2000 ohms.

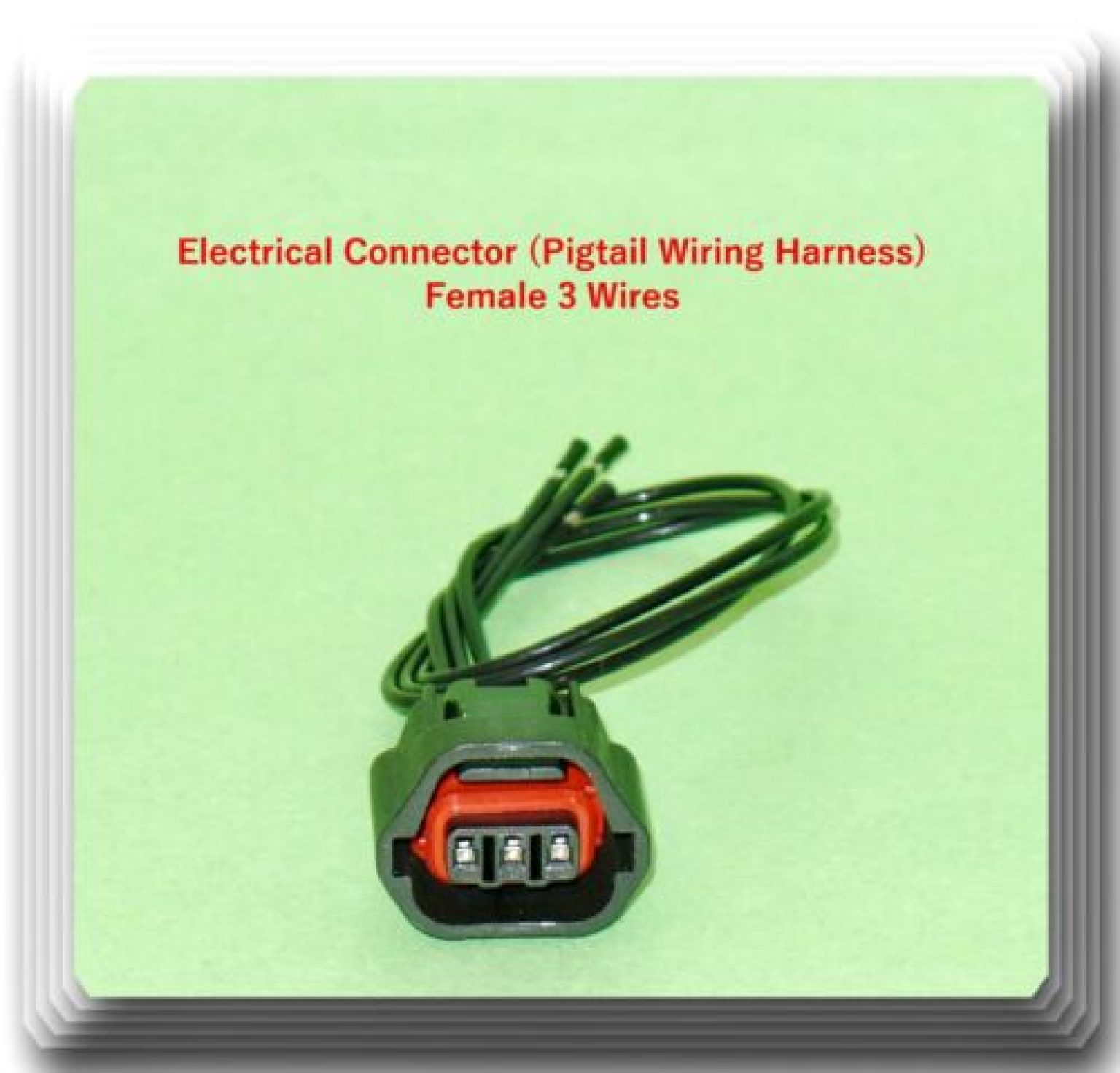

- Check the sensor’s connections. Make sure that the sensor is properly connected to the ECM and that the wires are not damaged.

Fun Facts of Crank Position Sensor

Here are some fun facts about crank position sensors:

- The crank position sensor is one of the most important sensors in the engine management system.

- The crank position sensor is responsible for timing the spark plugs and fuel injectors.

- The crank position sensor can also be used to detect misfires.

How to Crank Position Sensor

Here are the steps on how to crank position sensor:

- Locate the crank position sensor. The sensor is usually located on the side of the engine near the crankshaft.

- Disconnect the sensor’s electrical connector.

- Remove the sensor’s mounting bolts.

- Pull the sensor out of the engine.

- Install the new sensor in the reverse order of removal.

What if Crank Position Sensor

Here are some of the things that can happen if the crank position sensor fails:

- The engine will not start.

- The engine will run poorly.

- The engine will stall.

Listicle of Crank Position Sensor

Here is a listicle of the crank position sensor:

- It is a critical component of the engine management system.

- It is responsible for timing the spark plugs and fuel injectors.

- It can also be used to detect misfires.

- It is usually located on the side of the engine near the crankshaft.

- It is a relatively inexpensive sensor to replace.

Question and Answer

- What is a crank position sensor?

A crank position sensor is a device that detects the position of the crankshaft and sends this information to the engine control module (ECM). - What are the symptoms of a bad crank position sensor?

The symptoms of a bad crank position sensor can include engine stalling or hesitation, difficulty starting the engine, decreased engine power, and fuel economy problems. - How can I test a crank position sensor?

You can test a crank position sensor using a voltmeter or an oscilloscope. - How much does it cost to replace a crank position sensor?

The cost to replace a crank position sensor varies depending on the make and model of your vehicle. However, it is typically a relatively inexpensive repair.

Conclusion of What Does Crank Position Sensor Do

The crank position sensor is a critical component of the engine management system. It is responsible for timing the spark plugs and fuel injectors. The crank position sensor can also be used to detect misfires. If you are experiencing problems with your car’s engine, one of the first things you should check is the crank position sensor.