It’s like a sneaky little thief, silently lurking in the shadows of your engine, waiting for the perfect moment to strike. And when it does, your car suddenly starts making that dreaded squealing noise, leaving you stranded and frustrated.

That’s the pain of a broken fan belt, a seemingly insignificant component that can bring your vehicle to a screeching halt. But don’t despair! Finding the right fan belt size for your car is not as daunting as it may seem.

In this comprehensive guide, we’ll delve into the world of fan belts, providing you with all the knowledge you need to choose the perfect fit for your beloved vehicle and keep it running smoothly.

So, let’s buckle up and dive right in!

What is a Fan Belt?

A fan belt, also known as a serpentine belt, is a crucial component of your car’s engine. It’s a long, flexible belt that wraps around several pulleys, including the crankshaft, water pump, alternator, and power steering pump. As the engine runs, the fan belt rotates, driving these accessories and ensuring they function properly.

Without a properly sized fan belt, your car’s engine will not be able to cool itself effectively, charge the battery, or provide power steering. That’s why finding the right fan belt size is essential for the smooth and reliable operation of your vehicle.

History and Myth of Fan Belts: Unraveling the Tales

The history of fan belts is intertwined with the evolution of the automobile itself. Early cars used flat leather belts to drive their accessories. However, these belts were prone to stretching and breaking, leading to frequent breakdowns.

In the 1940s, the v-belt was introduced, offering improved durability and performance. V-belts had a trapezoidal cross-section, which allowed them to grip the pulleys more effectively. However, as engines became more complex, the need for a more efficient and compact drive system arose.

In the 1980s, the serpentine belt was developed. Serpentine belts had a serpentine pattern, which allowed them to wrap around multiple pulleys in a compact and efficient manner. They also had a self-tensioning mechanism, eliminating the need for manual adjustments. Today, serpentine belts are the standard drive system for most modern vehicles.

Hidden Secrets of Fan Belts: Unlocking the Mysteries

Fan belts may seem like simple components, but they play a critical role in your car’s performance. Here are a few hidden secrets about fan belts that you might not know:

• Fan belts are made of a combination of rubber and fiber. This unique blend provides the belt with strength, flexibility, and heat resistance.

• The ribs on a serpentine belt help to increase traction and prevent slippage. The more ribs a belt has, the more power it can transmit.

• Fan belts can stretch over time, leading to reduced tension and decreased efficiency. It’s important to replace fan belts at regular intervals to ensure optimal performance.

Recommendations: Choosing the Perfect Fit

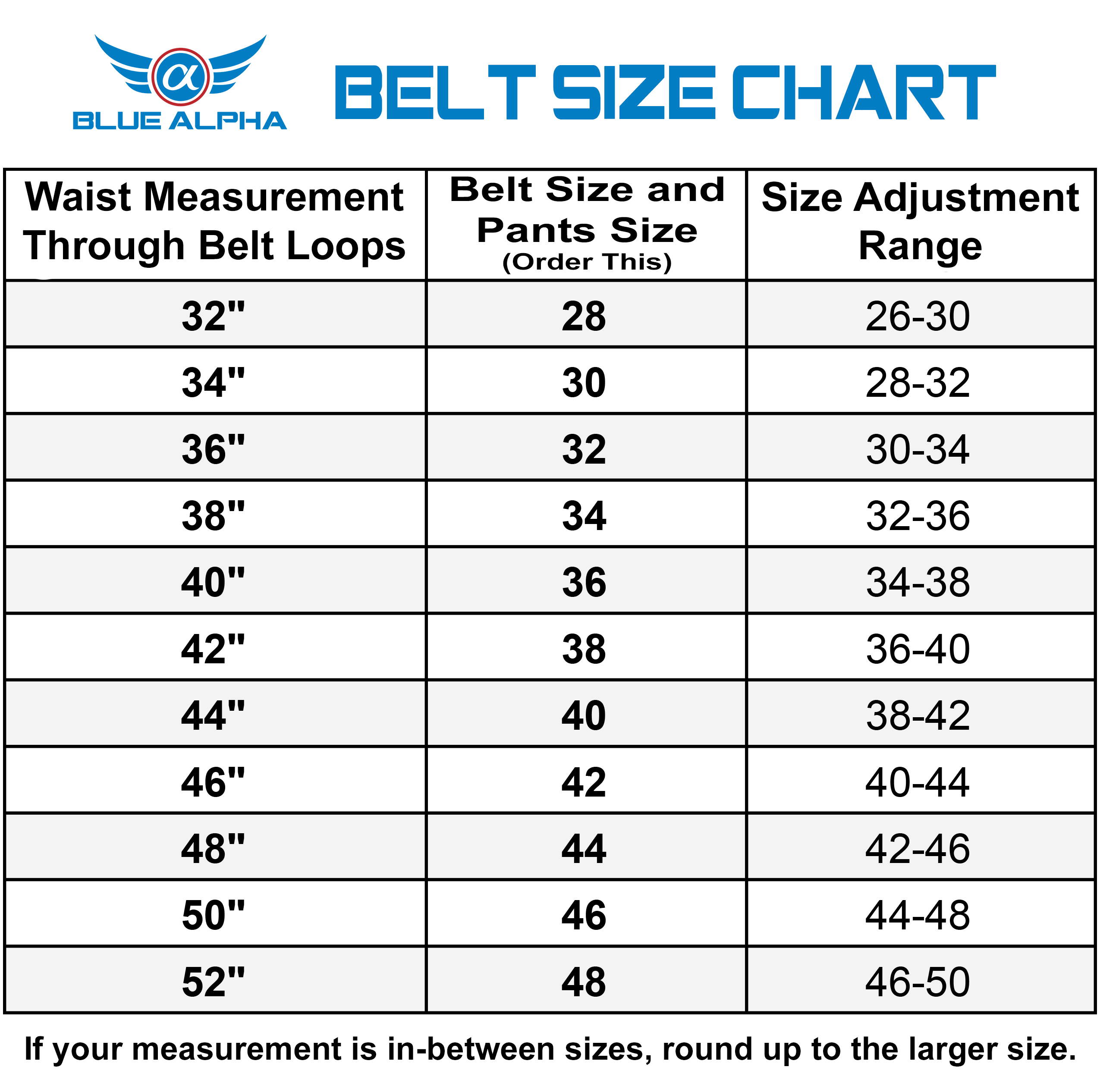

When choosing a fan belt for your vehicle, it’s crucial to select the right size. The belt should be long enough to wrap around all the pulleys without being too loose or too tight. Here are some recommendations to help you find the perfect fit:

• Refer to your vehicle’s owner’s manual. It will provide the specific fan belt size recommended for your make and model.

• Use a tape measure to determine the length of the existing fan belt. Find a belt that is the same length or slightly shorter.

• Consult with a mechanic or automotive parts store. They can help you identify the correct fan belt size based on your vehicle’s specifications.

How to Measure Fan Belt Size: A Step-by-Step Guide

Measuring the size of your fan belt is a simple process that requires only a few tools. Here’s a step-by-step guide:

1. Gather your tools: You’ll need a tape measure, a pen or marker, and a piece of paper.

2. Locate the fan belt: Open the hood and locate the fan belt. It’s usually a long, black belt that wraps around several pulleys.

3. Mark the belt: Use a pen or marker to mark the point where the belt meets the tensioner pulley.

4. Measure the belt: Use the tape measure to measure the distance between the two marks. This is the length of your fan belt.

Tips: Ensuring a Long and Healthy Fan Belt Life

Fan belts are designed to last for many years, but there are a few things you can do to extend their lifespan and prevent premature failure:

• Inspect your fan belt regularly for signs of wear, such as cracks, fraying, or glazing. Replace any worn belts immediately.

• Keep the engine bay clean and free of debris. Dirt and grime can accumulate on the belt and cause it to wear prematurely.

• Avoid overloading your vehicle’s electrical system. This can put extra strain on the fan belt and shorten its life.

Fun Facts: Did You Know?

Here are some fascinating facts about fan belts that you might not have known:

• The longest fan belt ever made was over 30 feet long! It was used on a massive diesel engine.

• Fan belts are also used in some industrial applications, such as driving conveyor belts and machinery.

• The tension on a fan belt is critical for its proper operation. Too much tension can damage the belt and the pulleys, while too little tension can cause the belt to slip.

How to Replace a Fan Belt: A DIY Guide

Replacing a fan belt is a relatively straightforward task that can be done in about an hour. Here’s a step-by-step guide to help you get the job done:

1. Gather your tools: You’ll need a wrench, a socket set, a new fan belt, and a pair of gloves.

2. Disconnect the battery: This will prevent any electrical accidents while you’re working.

3. Loosen the tensioner pulley: Use the wrench or socket set to loosen the tensioner pulley. This will allow you to remove the old belt.

4. Remove the old belt: Slide the old belt off the pulleys.

5. Install the new belt: Wrap the new belt around the pulleys in the correct order. Make sure the ribs on the belt match the grooves on the pulleys.

6. Tension the belt: Use the tensioner pulley to tension the belt. The belt should be tight enough to prevent slippage, but not so tight that it damages the pulleys.

7. Reconnect the battery: Reconnect the battery and start the engine. Check for any leaks or unusual noises.

What if My Fan Belt Breaks?

If your fan belt breaks while you’re driving, it’s important to pull over to a safe location as soon as possible. A broken fan belt can cause the engine to overheat, which can lead to serious damage. Here’s what to do if your fan belt breaks:

1. Pull over to a safe location: As soon as you notice any signs of a broken fan belt, such as squealing or loss of power, pull over to the side of the road and turn off the engine.

2. Open the hood: Once you’re safely parked, open the hood and inspect the fan belt. If it’s broken, you’ll need to replace it.

3. Replace the fan belt: If you’re comfortable doing so, you can replace the fan belt yourself. Follow the steps outlined in the “How to Replace a Fan Belt” section above.

4. Call for assistance: If you’re not comfortable replacing the fan belt yourself, call for assistance from a mechanic or towing service.

Listicle: 5 Things to Know About Fan Belts

Here’s a listicle of five things you should know about fan belts:

1. Fan belts are essential for the proper operation of your vehicle’s engine.

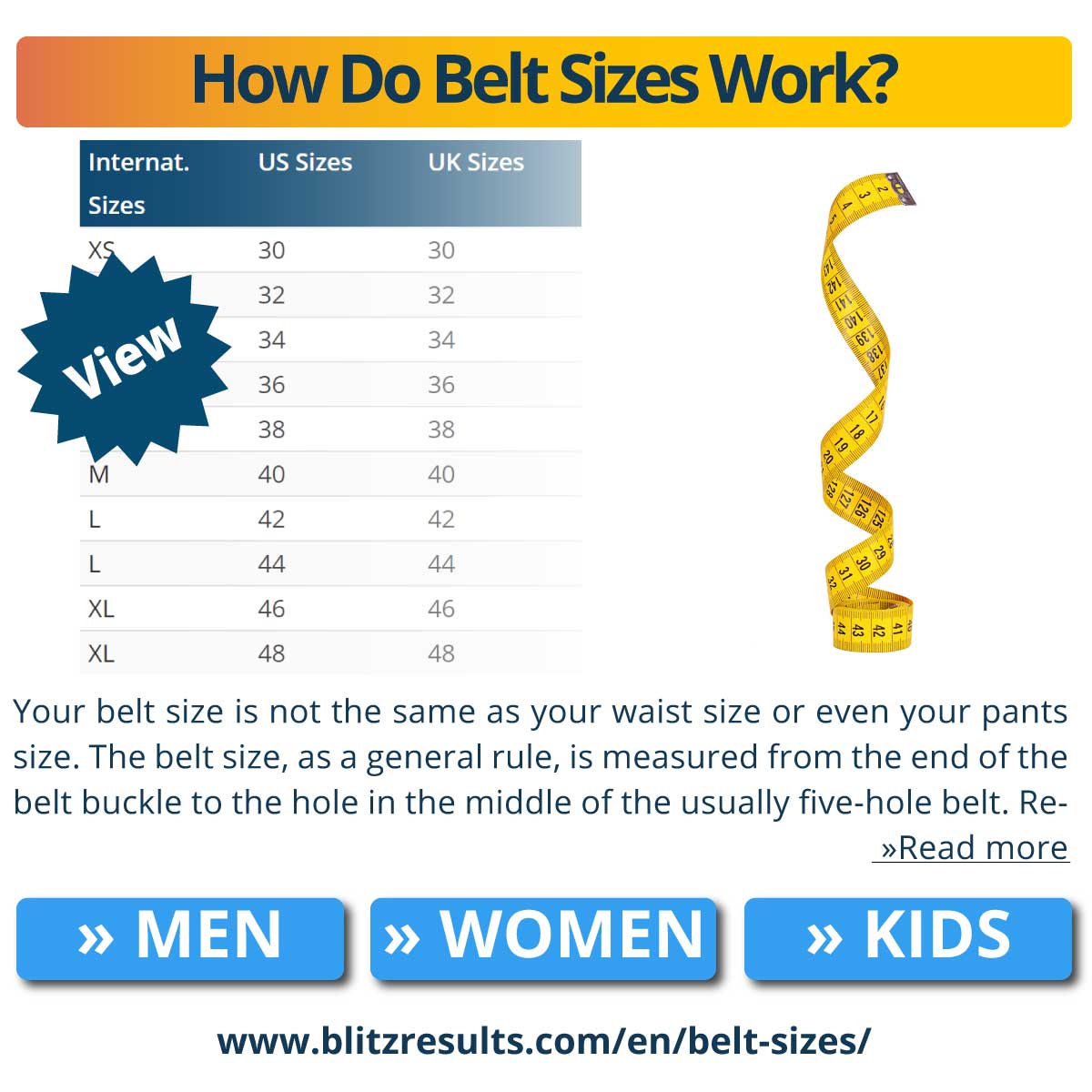

2. Fan belts come in a variety of sizes, so it’s important to select the right size for your vehicle.

3. Fan belts can stretch over time, so it’s important to replace them at regular intervals.

4. A broken fan belt can cause your engine to overheat, so it’s important to pull over to a safe location if you notice any signs of a broken belt.

5. Replacing a fan belt is a relatively