Do you want to know everything about V belts and pulleys? Then you need to read this ultimate guide. In this guide, we will cover everything you need to know about V belts and pulleys, from their history and myths to their hidden secrets.

If you are looking for a comprehensive guide on V belts and pulleys, then you have come to the right place. In this guide, we will cover everything you need to know about V belts and pulleys, from their history and myths to their hidden secrets.

What is V Belts and Pulleys?

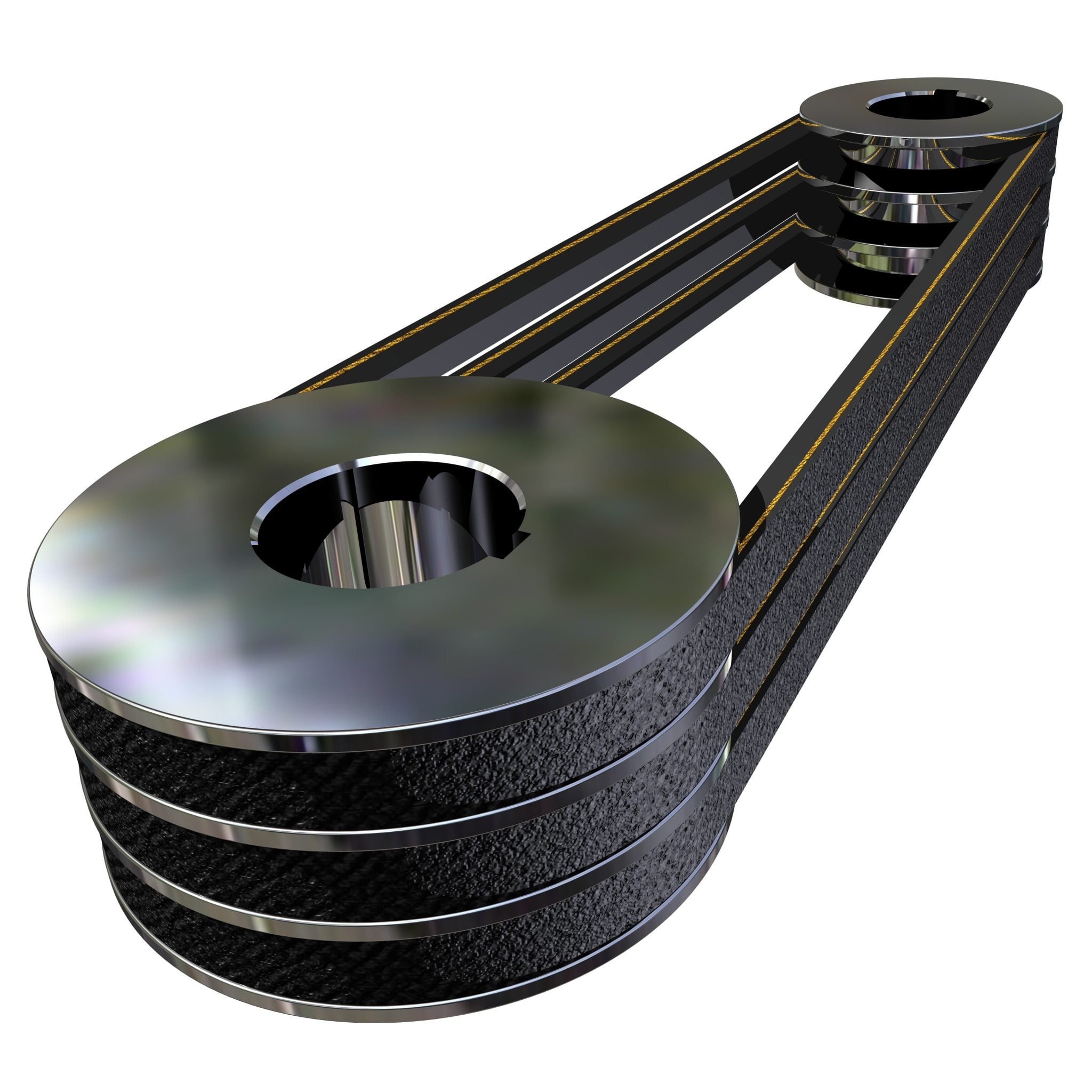

V belts and pulleys are used in a variety of applications, from automotive engines to industrial machinery. They are a simple but effective way to transmit power from one shaft to another. V belts are made of a flexible material, such as rubber or leather, and they have a V-shaped cross-section. Pulleys are grooved wheels that fit the V-shaped profile of the belt. When the belt is wrapped around the pulleys, it creates a frictional force that transmits power from one pulley to the other.

History and Myth of V Belts and Pulleys

V belts and pulleys have been used for centuries. The first known use of a V belt was in the 18th century, when it was used to drive a textile machine. Pulleys have been used for even longer, dating back to the ancient Greeks.

There are many myths and legends surrounding V belts and pulleys. One common myth is that V belts are more efficient than other types of belts. This is not true. In fact, V belts are less efficient than other types of belts, such as flat belts or timing belts.

Hidden Secrets of V Belts and Pulleys

There are many hidden secrets to V belts and pulleys. One secret is that V belts can be used to create a variable speed drive. This is a type of drive system that allows the speed of the output shaft to be varied. Another secret is that V belts can be used to create a serpentine belt drive. This type of drive system uses a single belt to drive multiple pulleys.

Recommendation of V Belts and Pulleys

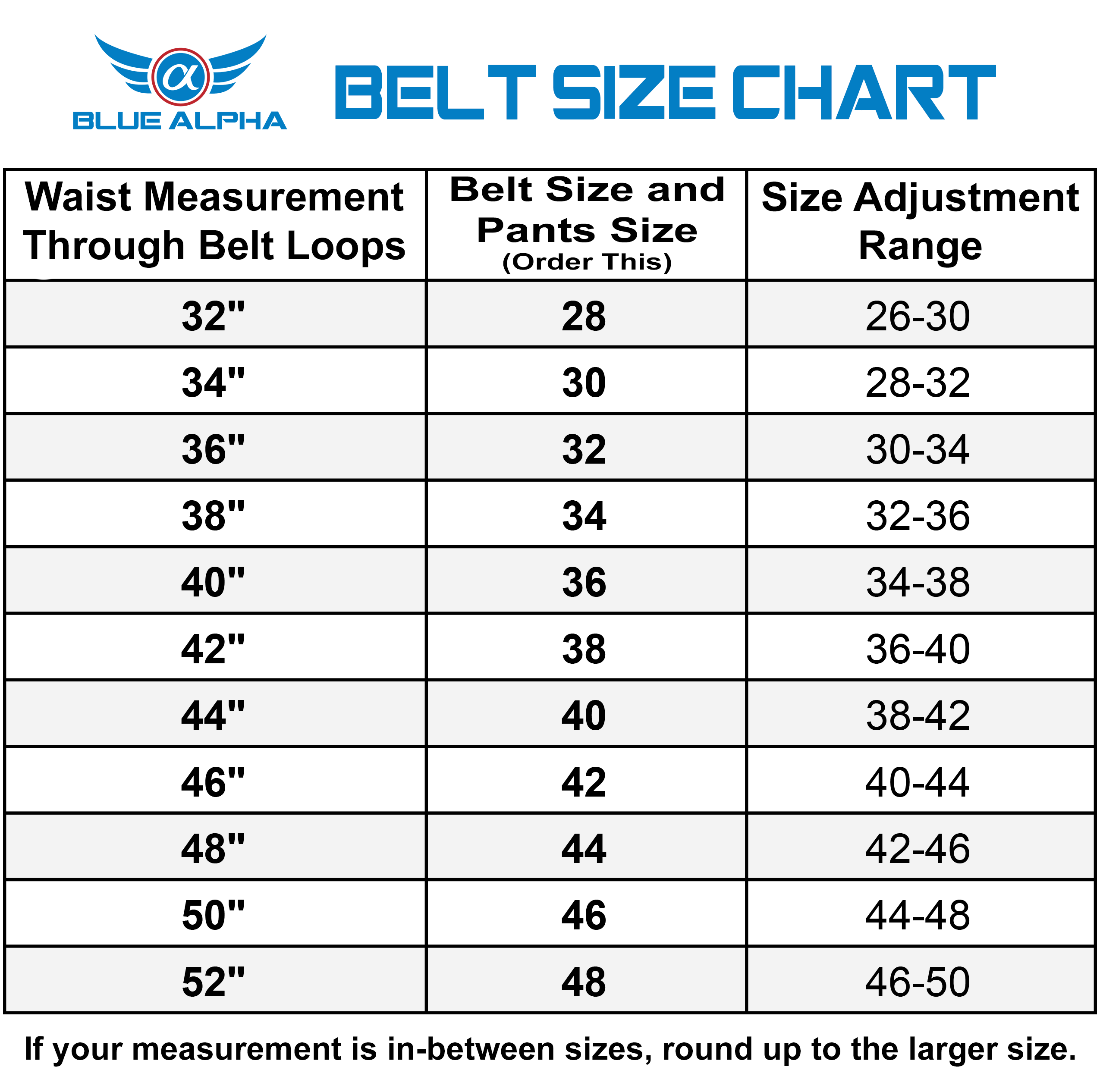

When choosing V belts and pulleys, there are a few things to keep in mind. First, you need to consider the power that the belt will be transmitting. Second, you need to consider the speed at which the belt will be running. Third, you need to consider the environment in which the belt will be used.

Once you have considered these factors, you can choose the right V belts and pulleys for your application.

V Belts and Pulleys in More Detail

V belts and pulleys are relatively simple devices, but they can be used to create a variety of complex drive systems. By understanding the basics of V belts and pulleys, you can design and build drive systems that meet your specific needs.

Tips for V Belts and Pulleys

Here are a few tips for using V belts and pulleys:

- Use the correct belt size. The belt should be tight enough to prevent slippage, but not so tight that it causes premature wear.

- Keep the belts clean and free of debris.

- Inspect the belts regularly for signs of wear or damage.

- Replace the belts if they show any signs of wear or damage.

V Belts and Pulleys in More Detail

In addition to the tips above, there are a few other things to keep in mind when using V belts and pulleys.

First, V belts are not self-tensioning. This means that you will need to tension the belt before using it. You can do this by using a belt tensioner.

Second, V belts can slip under certain conditions. This can be caused by a variety of factors, such as excessive load, improper tension, or misalignment.

If you are experiencing belt slip, you can try to increase the tension on the belt. If this does not solve the problem, you may need to replace the belt.

Fun Facts of V Belts and Pulleys

Here are a few fun facts about V belts and pulleys:

- V belts are made of a variety of materials, including rubber, leather, and polyurethane.

- Pulleys are made of a variety of materials, including metal, plastic, and wood.

- V belts and pulleys are used in a variety of applications, from automotive engines to industrial machinery.

- V belts and pulleys are a relatively simple but effective way to transmit power from one shaft to another.

How to V Belts and Pulleys

If you are not sure how to V belts and pulleys, you can follow these steps:

- Choose the right V belts and pulleys for your application.

- Mount the pulleys on the shafts.

- Wrap the belt around the pulleys.

- Tension the belt.

- Start the machine.

What if V Belts and Pulleys

If you are wondering what if V belts and pulleys, here are a few things to consider:

- What if the belt breaks?

- What if the pulley is misaligned?

- What if the belt is too loose or too tight?

If you are experiencing any problems with V belts and pulleys, you should consult with a qualified technician.

Listicle of V Belts and Pulleys

Here is a listicle of V belts and pulleys:

- V belts are made of a variety of materials, including rubber, leather, and polyurethane.

- Pulleys are made of a variety of materials, including metal, plastic, and wood.

- V belts and pulleys are used in a variety of applications, from automotive engines to industrial machinery.

- V belts and pulleys are a relatively simple but effective way to transmit power from one shaft to another.

- V belts are not self-tensioning.

- V belts can slip under certain conditions.

- If you are experiencing belt slip, you can try to increase the tension on the belt.

- If you are not sure how to V belts and pulleys, you can follow these steps:

- Choose the right V belts and pulleys for your application.

- Mount the pulleys on the shafts.

- Wrap the belt around the pulleys.

- Tension the belt.

- Start the machine.

Questions and Answer

- What are V belts and pulleys?

- How do V belts and pulleys work?

- What are the different types of V belts and pulleys?

- How do I choose the right V belts and pulleys for my application?

Conclusion of V Belts and Pulleys

V belts and pulleys are a simple but effective way to transmit power from one shaft to another. They are used in a variety of applications, from automotive engines to industrial machinery. By understanding the basics of V belts and pulleys, you can design and build drive systems that meet your specific needs.