1. V Belt And Pulley Systems: Optimizing Power Transmission

Every machine requires an efficient power transmission system to function optimally. V-belt and pulley systems are widely used for this purpose, offering numerous advantages. They are versatile, cost-effective, and can effectively transmit power over a wide range of speeds and distances.

Understanding V-belt and Pulley Systems

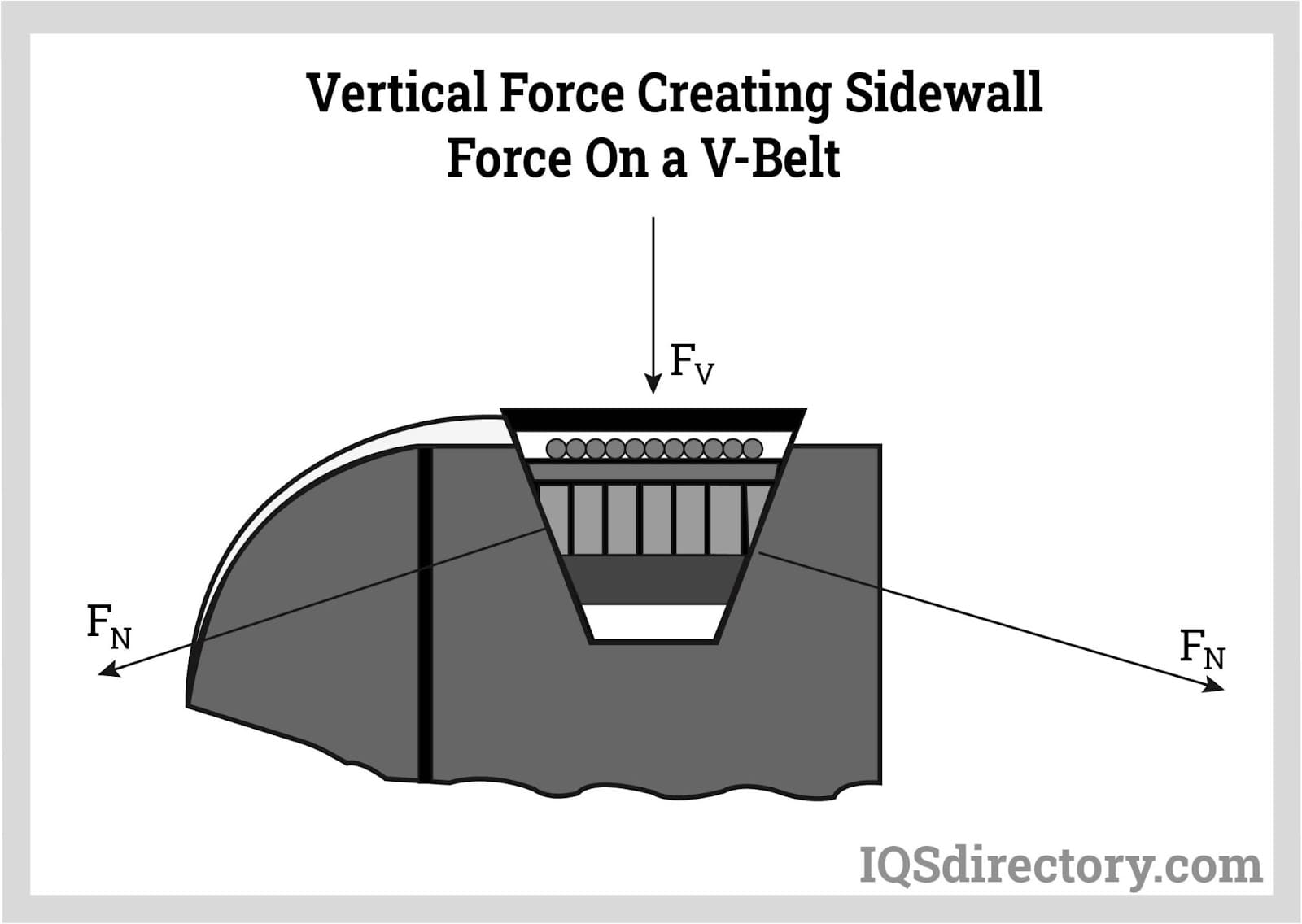

V-belts are trapezoidal-shaped belts that fit into grooved pulleys. The wedging action of the belt in the pulley creates friction, allowing power to be transmitted from one pulley to another. The system’s efficiency depends on factors such as belt tension, pulley alignment, and the materials used.

History and Evolution of V-belts and Pulleys

V-belts and pulleys have a long history, dating back to the 19th century. Initially used in textile machinery, they gradually gained popularity in various industries. Over time, advancements in materials and design have led to improved efficiency and durability.

Hidden Secrets of V-belt and Pulley Systems

Understanding the dynamics of V-belt and pulley systems is essential for optimal performance. Proper tensioning ensures efficient power transmission, while alignment prevents premature belt wear. The choice of belt and pulley materials can also significantly impact performance.

Recommendations for Effective V-belt and Pulley Systems

To ensure optimal performance, regular maintenance is crucial. Inspecting belts for wear or damage, checking pulley alignment, and adjusting tension as needed are essential. Using high-quality belts and pulleys from reputable manufacturers is also recommended.

Types of V-belts and Pulleys

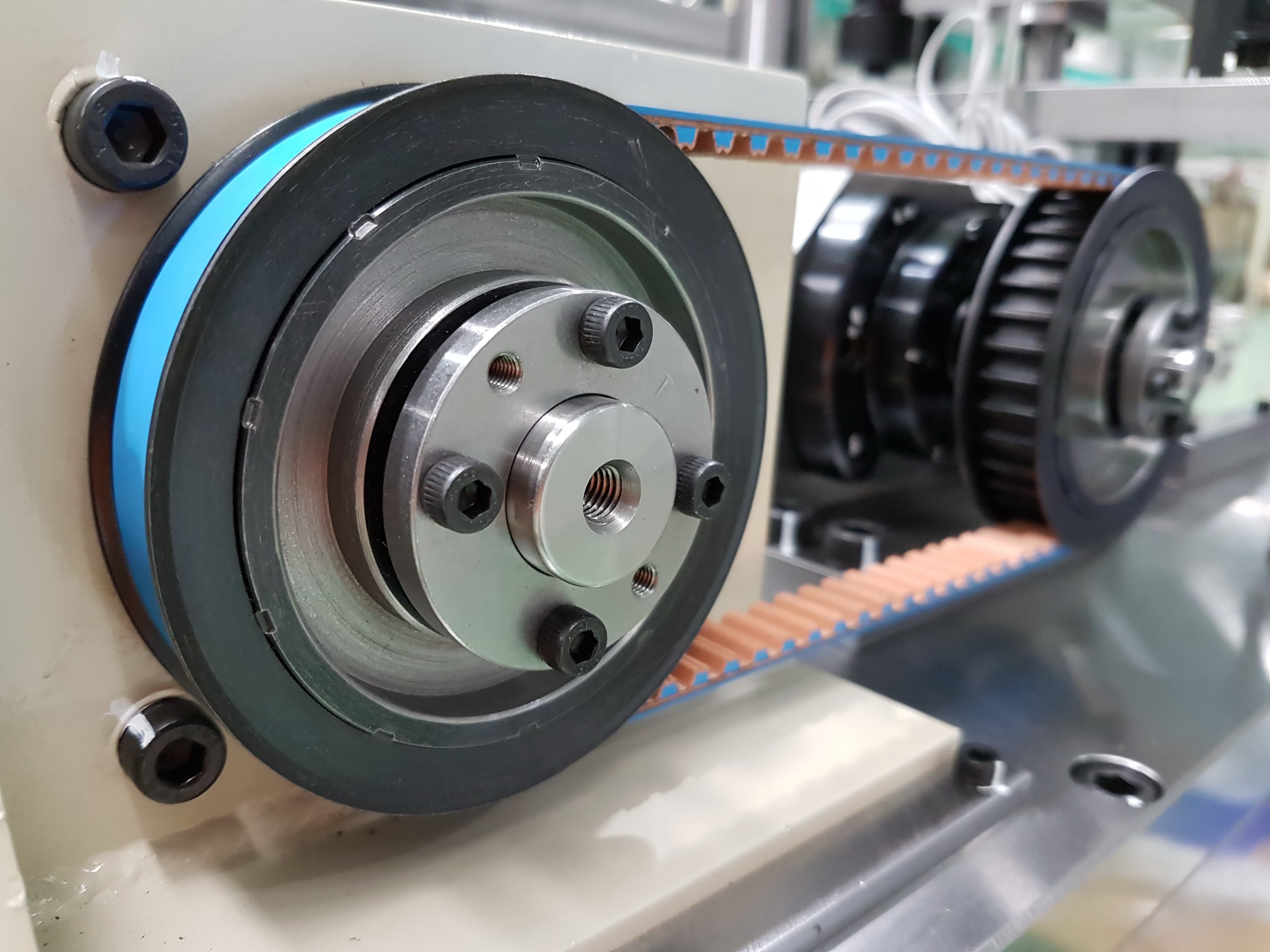

V-belts come in various sizes, profiles, and materials, including rubber, polyurethane, and Kevlar. Pulleys are typically made of cast iron, steel, or aluminum and can have different diameters and groove profiles. Choosing the right combination for the specific application is crucial.

Tips for Troubleshooting V-belt and Pulley Systems

Troubleshooting common issues with V-belt and pulley systems can save downtime and prevent costly repairs. Noise, vibration, belt slippage, and excessive wear can indicate problems. Regular inspections and proper maintenance can help identify and resolve issues early on.

Benefits of V-belt and Pulley Systems

V-belt and pulley systems offer numerous benefits, including:

Fun Facts about V-belt and Pulley Systems

Did you know?

How to Maintain V-belt and Pulley Systems

Maintaining V-belt and pulley systems involves:

What if V-belt and Pulley Systems Fail?

Failure of V-belt and pulley systems can lead to downtime, reduced productivity, and potential safety hazards. It can also damage other components in the machine. Regular maintenance and timely repairs can help prevent such failures.

Listicle of V-belt and Pulley Systems Applications

V-belt and pulley systems find applications in a wide range of industries, including:

Questions and Answers about V-belt and Pulley Systems

A: Factors include belt tension, pulley alignment, belt and pulley materials, and lubrication.

A: Refer to the manufacturer’s recommended tension values or use a belt tension gauge.

A: Uneven belt wear, noise, and vibration can indicate misalignment.

A: Regular inspections are recommended every 3-6 months, or more frequently in demanding operating conditions.

Conclusion of 1. V Belt And Pulley Systems: Optimizing Power Transmission

V-belt and pulley systems play a crucial role in power transmission, offering efficiency, versatility, and cost-effectiveness. Understanding their principles, maintenance requirements, and troubleshooting techniques is essential for optimizing performance and ensuring reliable operation in various applications.