6. The Driving Force: Understand V Belts And Pulleys

V belts and pulleys are essential components in many mechanical systems, but understanding how they work and interact can be a challenge. In this comprehensive guide, we’ll delve into the mechanics of V belts and pulleys, exploring their functions, advantages, and applications.

If you’re struggling to understand the complex interplay between V belts and pulleys, rest assured that you’re not alone. These components play a crucial role in power transmission, but their intricate design can be daunting.

This guide will provide a thorough understanding of V belts and pulleys. By comprehending their mechanics, you can enhance the efficiency of your mechanical systems and prevent costly downtime.

6. The Driving Force: Understand V Belts And Pulleys

V belts are flexible, power-transmitting components that engage with grooved pulleys. These belts are designed with a specific “V” shape that fits snugly into the grooves of the pulleys. The V-shaped profile ensures friction and prevents slippage, allowing for efficient power transmission.

Pulleys, on the other hand, are rotating wheels with grooves cut around their circumference. V belts run through these grooves, transferring power from one pulley to another. Pulleys come in various sizes and can be constructed from metal, plastic, or composite materials.

Together, V belts and pulleys form a drive system capable of transmitting power over long distances and at various speeds. This system is widely used in industries such as manufacturing, automotive, and agriculture.

History and Evolution of V Belts and Pulleys

The concept of V belts and pulleys dates back centuries. Early versions of these components were made of leather or canvas and used in various industrial applications. However, these materials were susceptible to wear and tear, limiting their efficiency and lifespan.

In the 19th century, the introduction of rubber and synthetic materials revolutionized V belt technology. These new materials were more durable, resistant to stretching and cracking, and provided longer service life.

Over time, V belts and pulleys have undergone continuous improvements, resulting in the high-performance and efficient systems we have today. Modern V belts are designed with robust materials and advanced manufacturing techniques, ensuring exceptional durability and reliability.

Unlocking the Hidden Secrets of V Belts and Pulleys

V belts and pulleys are more than just mechanical components; they hold secrets that can significantly impact the performance of your systems. Understanding these hidden secrets can help you optimize your operation and avoid costly downtime.

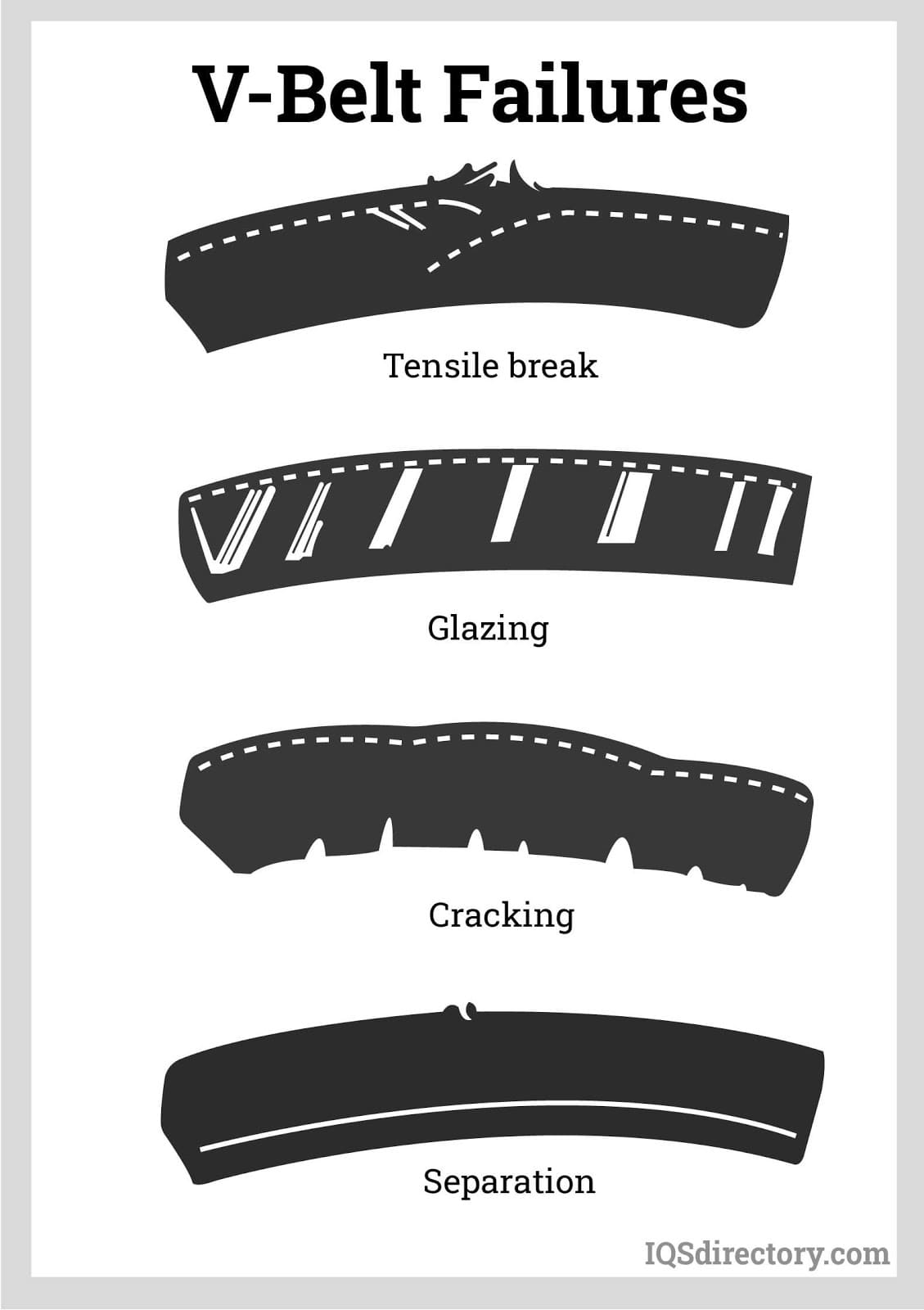

One key secret lies in the tension of the V belt. Proper tension is crucial for efficient power transmission and preventing premature belt failure. Too much tension can cause excessive stress on the belt and bearings, while too little tension can lead to slippage and reduced power transmission.

Another secret involves the alignment of the V belt and pulleys. Misalignment can lead to accelerated belt wear, power loss, and vibration. Regular inspection and alignment of the drive system are essential for maintaining optimal performance.

Recommendations for Selecting and Maintaining V Belts and Pulleys

Choosing the right V belt and pulley combination is crucial for optimal performance and longevity. Consider the following recommendations:

– Select V belts based on the power requirements, speed, and environmental conditions of your application.

– Choose pulleys that match the size and profile of your V belts.

– Properly tension the V belt according to the manufacturer’s specifications.

– Regularly inspect and align the drive system to ensure optimal performance.

– Store V belts and pulleys in a cool, dry place to prevent deterioration.

Tips for Efficient Use of V Belts and Pulleys

Maximize the efficiency of your V belt and pulley system with these practical tips:

– Use high-quality V belts and pulleys from reputable manufacturers.

– Avoid overloading the drive system to prevent premature belt failure.

– Monitor the temperature of the V belt during operation. Excessive heat can indicate over-tensioning or misalignment.

– Regularly clean the V belt and pulleys to remove dirt and debris that can affect performance.

– Replace V belts and pulleys as recommended by the manufacturer.

Fun Facts About V Belts and Pulleys

Did you know?

– V belts are used in a wide range of applications, from small lawnmowers to large industrial machinery.

– V belts can transmit power over distances of up to 100 feet.

– V pulleys are available in various materials, including cast iron, aluminum, and composite materials.

– The V-shaped profile of V belts prevents them from jumping off the pulleys, even at high speeds.

Conclusion of 6. The Driving Force: Understand V Belts And Pulleys

By understanding the mechanics of V belts and pulleys, you can optimize the performance and lifespan of your mechanical systems. Remember, proper selection, maintenance, and practices are crucial for efficient power transmission and minimizing downtime.