V belts and pulleys are essential components of modern industrial machinery. They are used to transmit power between shafts and pulleys, and their efficient operation is critical to maintaining productivity and profitability.

Inefficiencies in Industrial Machinery

Worn or damaged V belts and pulleys can lead to a number of problems, including power loss, slippage, and even catastrophic failure. These problems can result in costly downtime, lost production, and even safety hazards.

9. V Belts And Pulleys: Enhancing Industrial Productivity

V belts and pulleys are designed to provide reliable and efficient power transmission in a wide range of industrial applications. They are made from durable materials and precision-engineered to meet the demands of modern machinery.

By investing in high-quality V belts and pulleys, manufacturers can improve the efficiency and productivity of their operations. V belts and pulleys can help to reduce downtime, increase power transmission, and extend the life of machinery.

9. V Belts And Pulleys

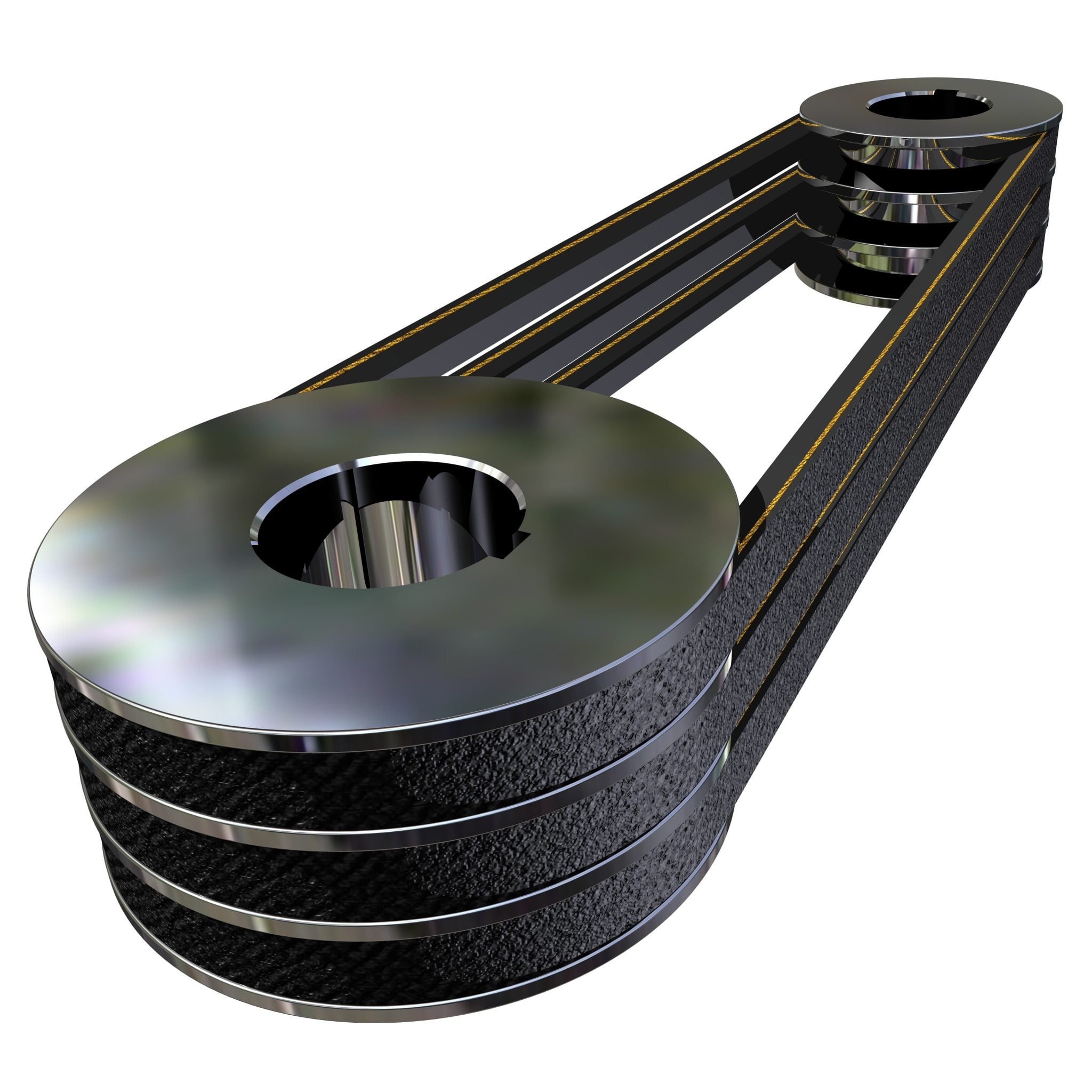

V belts and pulleys are a type of power transmission system that uses a V-shaped belt to drive a pulley. The belt is made of a flexible material, such as rubber or leather, and the pulley is a wheel with a V-shaped groove. The belt is placed around the pulley, and the grooves on the pulley help to keep the belt in place. As the pulley rotates, the belt moves around the pulley, transmitting power from the pulley to the belt.

V belts and pulleys are a versatile and efficient way to transmit power. They are used in a wide variety of applications, including automotive engines, industrial machinery, and agricultural equipment.

The History and Myth of V Belts and Pulleys

V belts and pulleys have a long and interesting history. The first V belt was invented in the 1850s by a man named John Gates. Gates was a farmer who was looking for a way to improve the efficiency of his threshing machine. He came up with the idea of using a V-shaped belt to drive the pulley on his threshing machine. The V-shaped belt provided more grip than a flat belt, and it was also more durable. Gates’ invention quickly became popular, and V belts and pulleys are now used in a wide variety of applications.

The Hidden Secret of V Belts and Pulleys

There is a hidden secret to V belts and pulleys that most people don’t know about. The secret is that V belts and pulleys can be used to create a variable speed drive. A variable speed drive is a device that allows you to change the speed of a shaft or pulley. This can be very useful in a variety of applications, such as controlling the speed of a motor or conveyor belt.

To create a variable speed drive, you simply need to use a V belt and pulley that have different diameters. The larger the pulley, the slower the speed of the shaft or pulley. The smaller the pulley, the faster the speed of the shaft or pulley.

Recommendations for V Belts and Pulleys

If you are looking for a way to improve the efficiency and productivity of your industrial machinery, then I highly recommend investing in high-quality V belts and pulleys. V belts and pulleys are a relatively inexpensive investment, and they can provide a significant return on investment.

Here are a few recommendations for choosing and using V belts and pulleys:

- Choose V belts and pulleys that are made from durable materials and precision-engineered.

- Make sure that the V belts and pulleys are the correct size for your application.

- Install and maintain V belts and pulleys according to the manufacturer’s instructions.

V Belts And Pulleys in Industrial Applications

V belts and pulleys are used in a wide variety of industrial applications, including:

- Automotive engines

- Industrial machinery

- Agricultural equipment

- Construction equipment

- Mining equipment

V belts and pulleys are a versatile and efficient way to transmit power. They are used in a wide variety of applications, and they can help to improve the efficiency and productivity of industrial machinery.

Tips for V Belts And Pulleys

Here are a few tips for using V belts and pulleys:

- Keep V belts and pulleys clean and free of debris.

- Inspect V belts and pulleys regularly for wear and damage.

- Replace V belts and pulleys when they show signs of wear or damage.

- Use the correct size V belts and pulleys for your application.

- Install and maintain V belts and pulleys according to the manufacturer’s instructions.

V Belts And Pulleys: A Critical Component of Industrial Machinery

V belts and pulleys are a critical component of industrial machinery. They transmit power between shafts and pulleys, and their efficient operation is essential for maintaining productivity and profitability. By investing in high-quality V belts and pulleys, manufacturers can improve the efficiency and productivity of their operations, reduce downtime, increase power transmission, and extend the life of machinery.

Fun Facts About V Belts And Pulleys

Here are a few fun facts about V belts and pulleys:

- The first V belt was invented in the 1850s by a man named John Gates.

- V belts and pulleys are used in a wide variety of applications, including automotive engines, industrial machinery, and agricultural equipment.

- V belts and pulleys can be used to create a variable speed drive.

- V belts and pulleys are a relatively inexpensive investment, and they can provide a significant return on investment.

How to Choose the Right V Belts And Pulleys

When choosing V belts and pulleys, it is important to consider the following factors:

- The type of application

- The power requirements

- The speed requirements

- The environmental conditions

Once you have considered these factors, you can choose the right V belts and pulleys for your application.

What If V Belts And Pulleys Fail?

If V belts and pulleys fail, it can lead to a number of problems, including:

- Power loss

- Slippage

- Catastrophic failure

These problems can result in costly downtime, lost production, and even safety hazards. Therefore, it is important to regularly inspect V belts and pulleys for wear and damage, and to replace them when necessary.

Here are a few things that can happen if V belts and pulleys fail:

- The machine may stop working.

- The machine may become damaged.

- The machine may become dangerous to operate.

Listicle of V Belts And Pulleys

Here is a listicle of V belts and pulleys:

- V belts are made of a flexible material, such as rubber or leather.

- Pulleys are wheels with a V-shaped groove.

- V belts and pulleys are used to transmit power between shafts and pulleys.

- V belts and pulleys are used in a wide variety of applications, including automotive engines, industrial machinery, and agricultural equipment.

- V belts and pulleys are a relatively inexpensive investment, and they can provide a significant return on investment.

Questions and Answers About V Belts And Pulleys

Here are a few questions and answers about V belts and pulleys:

What are V belts and pulleys?

V belts and pulleys are a type of power transmission system that uses a V-shaped belt to drive a pulley.

What are V belts made of?

V belts are made of a flexible material, such as rubber or leather.

What are pulleys made of?

Pulleys are wheels with a V-shaped groove.

What are V belts and pulleys used for?

V belts and pulleys are used to transmit power between shafts and pulleys.

Conclusion of 9. V Belts And Pulleys: Enhancing Industrial Productivity

V belts and pulleys are an essential component of industrial machinery. They are used to transmit power between shafts and pulleys, and their efficient operation is essential for maintaining productivity and profitability.

By investing in high-