How Heavy-Duty V Belt Tension Pulleys Ensure Smooth Industrial Power Transmission

When it comes to industrial power transmission, seamless operation is crucial. Heavy-duty V belt tension pulleys play a vital role in maintaining optimal tension in V-belts, ensuring efficient and reliable power transfer.

Misalignment, insufficient tension, and excessive wear can lead to premature belt failure, power loss, and downtime. Heavy-duty V belt tension pulleys address these issues by providing precise tension adjustment, minimizing vibration, and prolonging belt life.

The primary function of a heavy-duty V belt tension pulley is to maintain the correct tension in the V-belt drive. By adjusting the tension, it optimizes power transmission efficiency, reduces belt slippage, and prevents premature wear.

In addition to their tensioning capabilities, heavy-duty V belt tension pulleys also act as idler pulleys, guiding and supporting the belt while minimizing friction. This helps to extend belt life and reduce the risk of belt breakage due to excessive stress or misalignment.

Importance of Heavy-Duty V Belt Tension Pulleys in Industrial Power Transmission

Heavy-duty V belt tension pulleys are essential components in industrial power transmission systems for several reasons. First, they maintain optimal belt tension, which prevents belt slippage and ensures efficient power transfer. Proper tension also reduces belt wear and tear, resulting in extended belt life.

Secondly, heavy-duty V belt tension pulleys eliminate harmful vibrations caused by misaligned or loose belts. These vibrations can damage other components in the power transmission system, leading to costly downtime and repairs.

Thirdly, these pulleys provide support for the V-belts, reducing the risk of belt bending or breaking. This is particularly important in high-torque applications where belts are subject to significant stresses.

History and Evolution of Heavy-Duty V Belt Tension Pulleys

Heavy-duty V belt tension pulleys have a rich history in industrial power transmission. The first V-belts were introduced in the early 1900s, revolutionizing the way power was transmitted in machines. As V-belts became more popular, the need for reliable and efficient tensioning systems grew.

Early tension pulleys were made of cast iron or steel and were relatively simple in design. Over time, as power transmission demands increased, so did the need for more robust and durable pulleys. Today, heavy-duty V belt tension pulleys are engineered with advanced materials and precision machining techniques to withstand extreme conditions and provide exceptional performance.

Unveiling the Secrets of Heavy-Duty V Belt Tension Pulleys

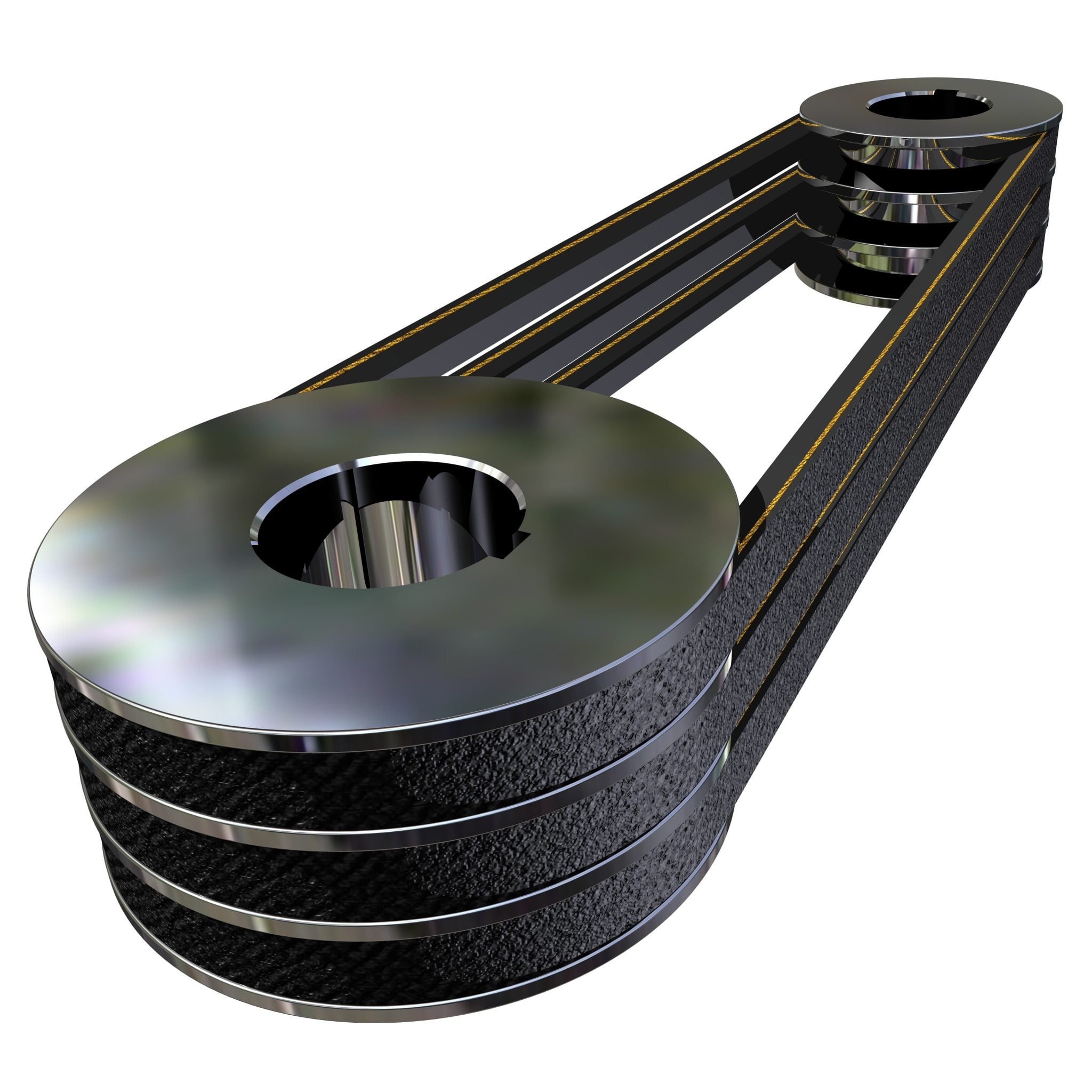

The inner workings of a heavy-duty V belt tension pulley are a testament to engineering ingenuity. These pulleys typically consist of a heavy-duty frame, a precision-machined sheave, and a spring-loaded tensioning mechanism.

The frame provides a solid foundation for the pulley and protects it from external impacts. The sheave is designed to match the profile of the V-belt, ensuring proper engagement and power transmission. The spring-loaded tensioning mechanism allows for precise adjustment of belt tension, ensuring optimal performance.

Recommendations for Selecting and Installing Heavy-Duty V Belt Tension Pulleys

Selecting and installing the right heavy-duty V belt tension pulley is crucial for ensuring optimal performance and longevity. Here are some key recommendations:

- Choose a pulley with a sheave diameter that matches the size of the V-belt being used.

- Ensure that the pulley has a robust frame capable of withstanding the applied loads.

- Use a tensioning mechanism that allows for precise adjustment of belt tension.

- Follow the manufacturer’s instructions for proper installation and alignment.

Advantages of Embracing Heavy-Duty V Belt Tension Pulleys

Investing in heavy-duty V belt tension pulleys offers numerous advantages for industrial power transmission systems:

- Improved power transmission efficiency and reduced energy consumption

- Extended belt life and reduced maintenance costs

- Elimination of harmful vibrations and reduced noise levels

- Enhanced reliability and reduced downtime

Tips for Maintaining and Troubleshooting Heavy-Duty V Belt Tension Pulleys

To ensure optimal performance and longevity of heavy-duty V belt tension pulleys, regular maintenance and troubleshooting are essential:

- Inspect pulleys regularly for wear, misalignment, or damage.

- Adjust belt tension as needed to maintain optimal performance.

- Lubricate pulleys according to the manufacturer’s recommendations.

- If vibration or excessive noise is observed, investigate the root cause and take corrective actions.

Benefits of Implementing Heavy-Duty V Belt Tension Pulleys

Implementing heavy-duty V belt tension pulleys in industrial power transmission systems results in numerous benefits:

- Increased productivity and efficiency

- Reduced operating costs and improved profitability

- Enhanced safety and compliance with industry standards

- Reduced environmental impact through energy savings

Fun Facts about Heavy-Duty V Belt Tension Pulleys

Here are some interesting facts about heavy-duty V belt tension pulleys:

- Heavy-duty V belt tension pulleys can withstand extreme temperatures, ranging from -40°C to 100°C.

- These pulleys are available in various materials, including cast iron, steel, and aluminum.

- Some heavy-duty V belt tension pulleys are equipped with advanced features, such as automated tensioning systems and vibration dampening mechanisms.

How to Use and Optimize Heavy-Duty V Belt Tension Pulleys

To use and optimize heavy-duty V belt tension pulleys effectively, follow these steps:

- Install the pulley correctly according to the manufacturer’s instructions.

- Adjust belt tension using the provided tensioning mechanism.

- Monitor belt tension regularly and make adjustments as needed.

- Inspect the pulley for any signs of wear or damage regularly.

What if Heavy-Duty V Belt Tension Pulleys Fail?

Failure of heavy-duty V belt tension pulleys can lead to several consequences:

- Belt slippage and reduced power transmission efficiency

- Premature belt wear and failure

- Excessive vibration and noise

- Damage to other components in the power transmission system

Listicle: Key Considerations for Heavy-Duty V Belt Tension Pulleys

- Sheave diameter and compatibility with belt size

- Frame strength and durability

- Tensioning mechanism and adjustability

- Material selection and corrosion resistance

- Maintenance and troubleshooting procedures

Questions and Answers about Heavy-Duty V Belt Tension Pulleys

- Q: What is the primary function of a heavy-duty V belt tension pulley?

A: To maintain optimal belt tension, prevent slippage, and reduce wear. - Q: How do heavy-duty V belt tension pulleys eliminate vibration?

A: By supporting the belt and preventing misalignment, reducing harmful vibrations. - Q: What are the benefits of using heavy-duty V belt tension pulleys?

A: Improved power transmission efficiency, extended belt life, reduced noise, and enhanced reliability. - Q: How often should heavy-duty V belt tension pulleys be inspected?

A: Regularly, as per the manufacturer’s recommendations, to detect any signs of wear or damage.

Conclusion of Heavy-Duty V Belt Tension Pulley For Industrial Power Transmission

Heavy-duty V belt tension pulleys play a vital role in industrial power transmission systems, ensuring efficient and reliable power transfer. By maintaining optimal belt tension, minimizing vibration, and reducing wear, these pulleys contribute to increased productivity, reduced maintenance costs, and enhanced safety in industrial operations. Implementing high-quality heavy-duty V belt tension pulleys is an investment in the long-term performance and reliability of your power transmission system.