Industrial V-Belts and Pulleys: A Vital Component for Power Transmission

In the industrial realm, the seamless transmission of power is crucial to ensure optimal performance and efficiency. Industrial V-belts and pulleys play a pivotal role in this regard, providing a reliable and durable means of power transmission across a wide range of applications. However, it’s important to address the challenges and intricacies associated with optimizing this system to ensure maximum functionality and efficiency.

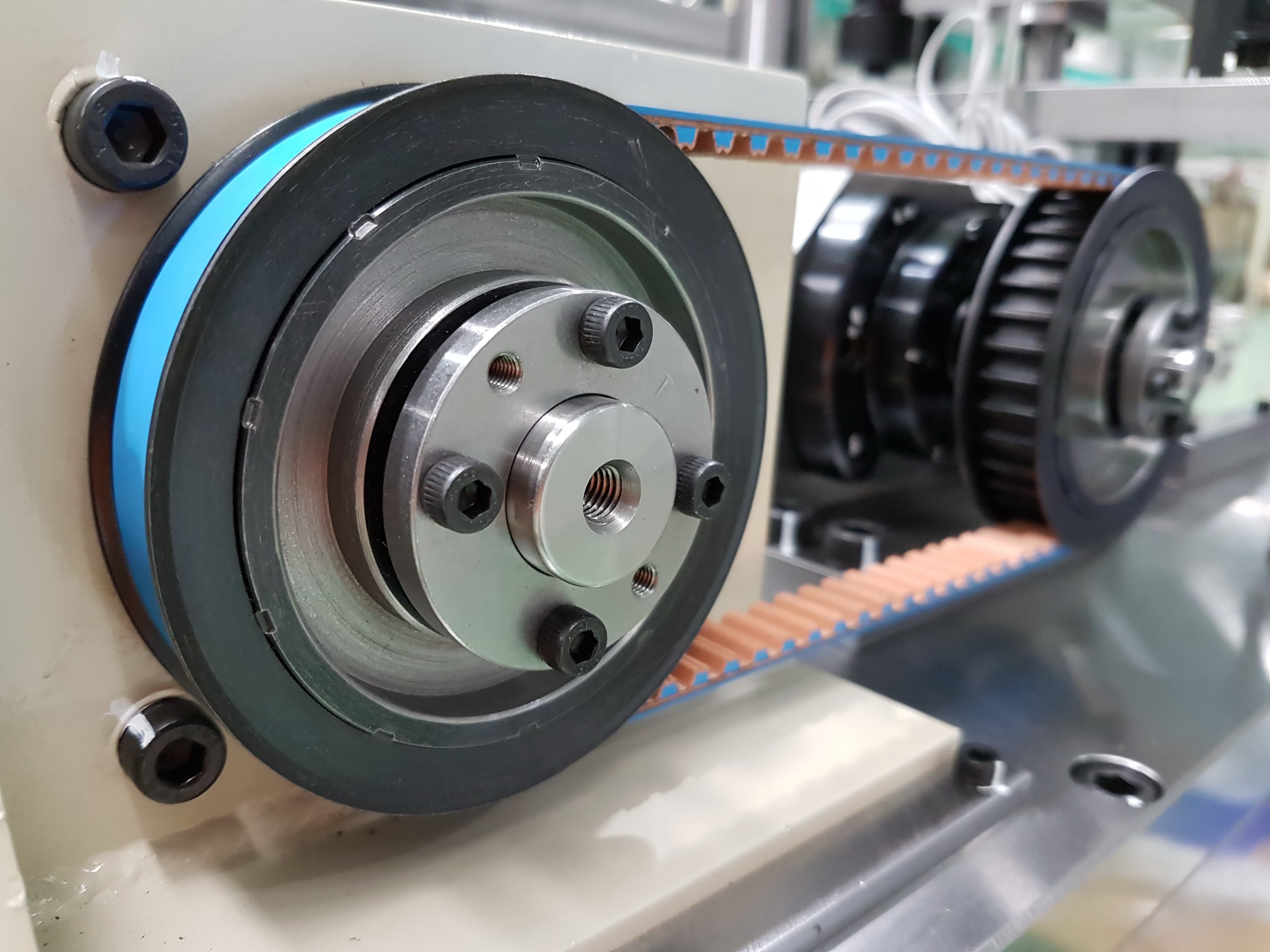

Industrial V-belt and pulley systems are designed to transfer power between two or more shafts, facilitating the smooth operation of machinery, equipment, and processes. These systems are commonly utilized in a diverse array of industries, including manufacturing, agriculture, construction, and automotive.

Industrial V-belts and pulleys offer several advantages over other power transmission methods. They are relatively inexpensive to manufacture and maintain, have a high power transmission capacity, and can be used in a variety of applications, including high-speed and high-torque environments. However, it’s essential to consider the potential drawbacks, such as the need for regular maintenance and the possibility of slippage or failure if not properly installed or maintained.

Industrial V-Belt And Pulley System For Power Transmission And Drive Applications

Industrial V-belts are made of a flexible material, typically rubber or polyurethane, and have a V-shaped cross-section. They are designed to fit into the grooves of pulleys, which are typically made of metal or plastic. The V-shape of the belt helps to keep it in place on the pulley, even under high loads.

Industrial V-belt and pulley systems are used in a wide variety of applications, including:

- Automotive engines

- Industrial machinery

- Agricultural equipment

- Construction equipment

- Mining equipment

What Is Industrial V-Belt And Pulley System For Power Transmission And Drive Applications?

Industrial V-belts and pulleys are a type of power transmission system that uses a V-shaped belt to transmit power between two shafts. The belt is made of a flexible material, such as rubber or polyurethane, and has a V-shaped cross-section. The pulleys are typically made of metal or plastic, and have a V-shaped groove that the belt fits into.

The V-shaped belt helps to keep the belt in place on the pulley, even under high loads. This makes V-belt and pulley systems ideal for applications where high torque is required, such as in automotive engines and industrial machinery.

History And Myth Of Industrial V-Belt And Pulley System For Power Transmission And Drive Applications

The first V-belt was developed in the early 1900s by a man named John Gates. Gates was working on a new type of engine for his automobile, and he needed a way to transmit power from the engine to the wheels. He experimented with different types of belts, and he eventually developed a V-shaped belt that was much more efficient than the flat belts that were commonly used at the time.

Gates’ V-belt was quickly adopted by other manufacturers, and it soon became the standard for power transmission in automobiles. Today, V-belts are used in a wide variety of applications, from small appliances to large industrial machines.

Hidden Secret Of Industrial V-Belt And Pulley System For Power Transmission And Drive Applications

One of the hidden secrets of V-belt and pulley systems is that they can be used to transmit power over long distances. This is because the V-shaped belt can be wrapped around the pulleys in a variety of ways, which allows for a wide range of configurations.

This makes V-belt and pulley systems ideal for applications where the power source and the driven equipment are located far apart, such as in wind turbines and conveyor systems.

Recommendation Of Industrial V-Belt And Pulley System For Power Transmission And Drive Applications

When choosing a V-belt and pulley system for your application, there are a few things to keep in mind:

- The power that you need to transmit

- The speed at which you need to transmit power

- The distance between the power source and the driven equipment

Once you have considered these factors, you can choose the appropriate V-belt and pulley system for your needs.

Industrial V-Belt And Pulley System For Power Transmission And Drive Applications

Industrial V-belt and pulley systems are available in a wide variety of sizes and configurations. They can be used to transmit power from a variety of sources, including electric motors, gasoline engines, and diesel engines.

V-belt and pulley systems are relatively easy to install and maintain. They are also very efficient, and they can last for many years with proper care.

Tips Of Industrial V-Belt And Pulley System For Power Transmission And Drive Applications

Here are a few tips for getting the most out of your V-belt and pulley system:

- Keep the belts and pulleys clean and free of debris.

- Inspect the belts and pulleys regularly for wear and tear.

- Replace the belts and pulleys when they show signs of wear or damage.

- Use the correct belt tension. If the belt is too loose, it will slip and lose power. If the belt is too tight, it will wear out prematurely.

Industrial V-Belt And Pulley System For Power Transmission And Drive Applications

Industrial V-belt and pulley systems are a reliable and efficient way to transmit power. By following these tips, you can get the most out of your V-belt and pulley system.

Fun Facts Of Industrial V-Belt And Pulley System For Power Transmission And Drive Applications

Here are some fun facts about V-belt and pulley systems:

- The largest V-belt ever made was over 100 feet long.

- V-belts are used in a wide variety of applications, from small appliances to large industrial machines.

- V-belt and pulley systems are very efficient, and they can last for many years with proper care.

How To Industrial V-Belt And Pulley System For Power Transmission And Drive Applications

To install a V-belt and pulley system, you will need the following tools:

- A wrench

- A screwdriver

- A pair of pliers

Follow these steps to install a V-belt and pulley system:

1. Remove the old belt.

2. Clean the pulleys.

3. Install the new belt.

4. Adjust the belt tension.

5. Tighten the bolts.

What If Industrial V-Belt And Pulley System For Power Transmission And Drive Applications?

If your V-belt and pulley system is not working properly, it can cause a variety of problems. These problems can include:

- Slipping

- Vibration

- Noise

- Premature wear

If you experience any of these problems, you should inspect your V-belt and pulley system for damage or wear. You should also check the belt tension. If the belt is too loose or too tight, it can cause problems.

Listicle Of Industrial V-Belt And Pulley System For Power Transmission And Drive Applications

Here is a listicle of the benefits of using V-belt and pulley systems:

- They are efficient.

- They are reliable.

- They are cost-effective.

- They are easy to