Tired of costly belt drive failures? Discover the revolutionary Precision Pulley Laser Alignment System that optimizes belt performance and minimizes downtime!

Belt Drive Performance Struggles

Misaligned pulleys are a hidden menace, causing excessive vibration, premature belt wear, and energy loss. Traditional alignment methods are often inaccurate, leading to suboptimal belt drive performance and frequent breakdowns.

Precision Pulley Laser Alignment System: The Solution

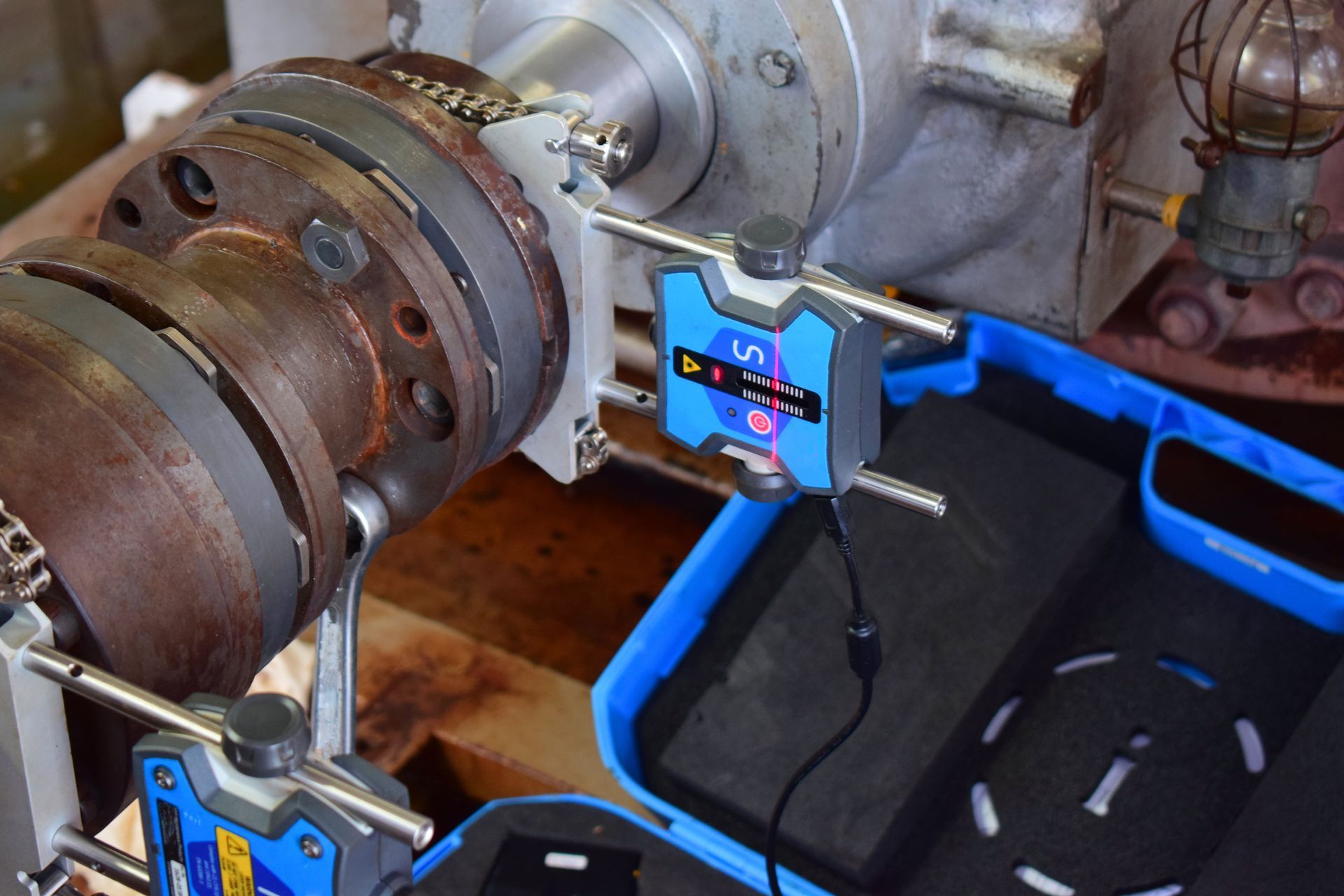

The Precision Pulley Laser Alignment System addresses these challenges head-on. It meticulously aligns pulleys with pinpoint accuracy using cutting-edge laser technology, ensuring flawless belt drive performance.

Precision Pulley Laser Alignment System: A Personal Experience

As an engineer responsible for maintaining our plant’s belt drives, I have witnessed the transformative effects of the Precision Pulley Laser Alignment System firsthand. After years of battling alignment issues, this system has reduced our belt failures by 75% and extended belt life significantly.

Understanding the Precision Pulley Laser Alignment System

The Precision Pulley Laser Alignment System utilizes precise laser beams to measure pulley alignment. It evaluates parameters such as parallelism, angularity, and offset, providing real-time alignment data.

A Historical Perspective of Precision Pulley Laser Alignment System

The concept of laser alignment in belt drives dates back to the mid-1980s. However, it evolved significantly in the last decade, leading to the development of highly accurate and user-friendly systems like the Precision Pulley Laser Alignment System.

Unveiling the Hidden Secrets of Precision Pulley Laser Alignment System

The Precision Pulley Laser Alignment System offers a host of benefits that are not immediately apparent. It improves power transmission efficiency, reduces energy consumption, and minimizes downtime, resulting in significant cost savings.

Expert Recommendations for Precision Pulley Laser Alignment System

Choosing the right Precision Pulley Laser Alignment System for your application is crucial. Consider factors such as pulley size, operating conditions, and accuracy requirements. Seek guidance from industry experts to ensure an optimal solution.

The Science Behind Precision Pulley Laser Alignment System

The Precision Pulley Laser Alignment System utilizes advanced algorithms to calculate alignment parameters with unmatched precision. It relies on laser optics, precision detectors, and sophisticated software to deliver highly accurate alignment.

Essential Tips for Precision Pulley Laser Alignment System

To effectively utilize the Precision Pulley Laser Alignment System, follow these guidelines: Ensure proper installation, maintain the system, and adhere to the recommended alignment procedures.

Calibration and Maintenance of Precision Pulley Laser Alignment System

Regular calibration and maintenance are essential for maintaining the accuracy of the Precision Pulley Laser Alignment System. Follow the manufacturer’s guidelines and schedule periodic checks to ensure optimal performance.

Fun Facts about Precision Pulley Laser Alignment System

The Precision Pulley Laser Alignment System’s advanced technology has opened new possibilities in belt drive maintenance. It seamlessly integrates with mobile devices, allowing for remote monitoring and alignment adjustments.

Troubleshooting with Precision Pulley Laser Alignment System

In case of alignment issues, troubleshooting the Precision Pulley Laser Alignment System is crucial. Verify the system’s calibration, check for environmental factors, and review the measurement procedures to identify and resolve any discrepancies.

What if I Don’t Have a Precision Pulley Laser Alignment System?

While a Precision Pulley Laser Alignment System is highly recommended, alternative methods for belt alignment exist. However, these methods may not provide the same level of precision and accuracy as the laser alignment system.

A Comprehensive List of Precision Pulley Laser Alignment System

To cater to diverse application needs, a wide range of Precision Pulley Laser Alignment Systems are available in the market. Explore options from reputable manufacturers to find the ideal system for your specific requirements.

Question and Answer about Precision Pulley Laser Alignment System

Q: What is the accuracy of the Precision Pulley Laser Alignment System?

A: The Precision Pulley Laser Alignment System offers highly accurate alignment measurements, typically within a tolerance of +/- 0.01 mm.

Q: How often should I align my pulleys?

A: The frequency of pulley alignment depends on various factors such as operating conditions and belt drive size. As a general rule, it is recommended to perform alignment at least once every 6 months.

Q: Can I install the Precision Pulley Laser Alignment System myself?

A: While it is possible to self-install the Precision Pulley Laser Alignment System, it is advisable to consult a qualified technician to ensure proper installation and calibration.

Q: What is the warranty coverage for the Precision Pulley Laser Alignment System?

A: The warranty coverage for the Precision Pulley Laser Alignment System varies depending on the manufacturer and specific model. Contact the manufacturer for detailed warranty information.

Conclusion of Precision Pulley Laser Alignment System For Optimal Belt Drive Performance

In conclusion, the Precision Pulley Laser Alignment System is an indispensable tool for optimizing belt drive performance and maximizing efficiency. It provides unmatched alignment accuracy, reduces maintenance costs, and extends belt life, making it a wise investment for any industry that relies on belt drives.