Tired of struggling with cracked or broken aluminum items? Say goodbye to costly repairs and time-consuming welding! Introducing the revolutionary Liquid Weld – your ultimate solution for quick and effective aluminum fixes.

If you’ve ever faced the frustration of dealing with damaged aluminum objects, you know the struggle. Traditional repair methods can be expensive, require specialized equipment, and often leave unsightly marks. But now, there’s a better way!

Aluminum Repair Revolution: Liquid Weld For Quick And Effective Aluminum Fixes

Liquid Weld is a cutting-edge solution that transforms aluminum repair. This innovative product is specially formulated to bond aluminum surfaces together, creating a strong and durable joint without the need for welding or soldering. It’s the perfect solution for a wide range of aluminum repairs, from cracked car rims to leaky plumbing.

What is Liquid Weld?

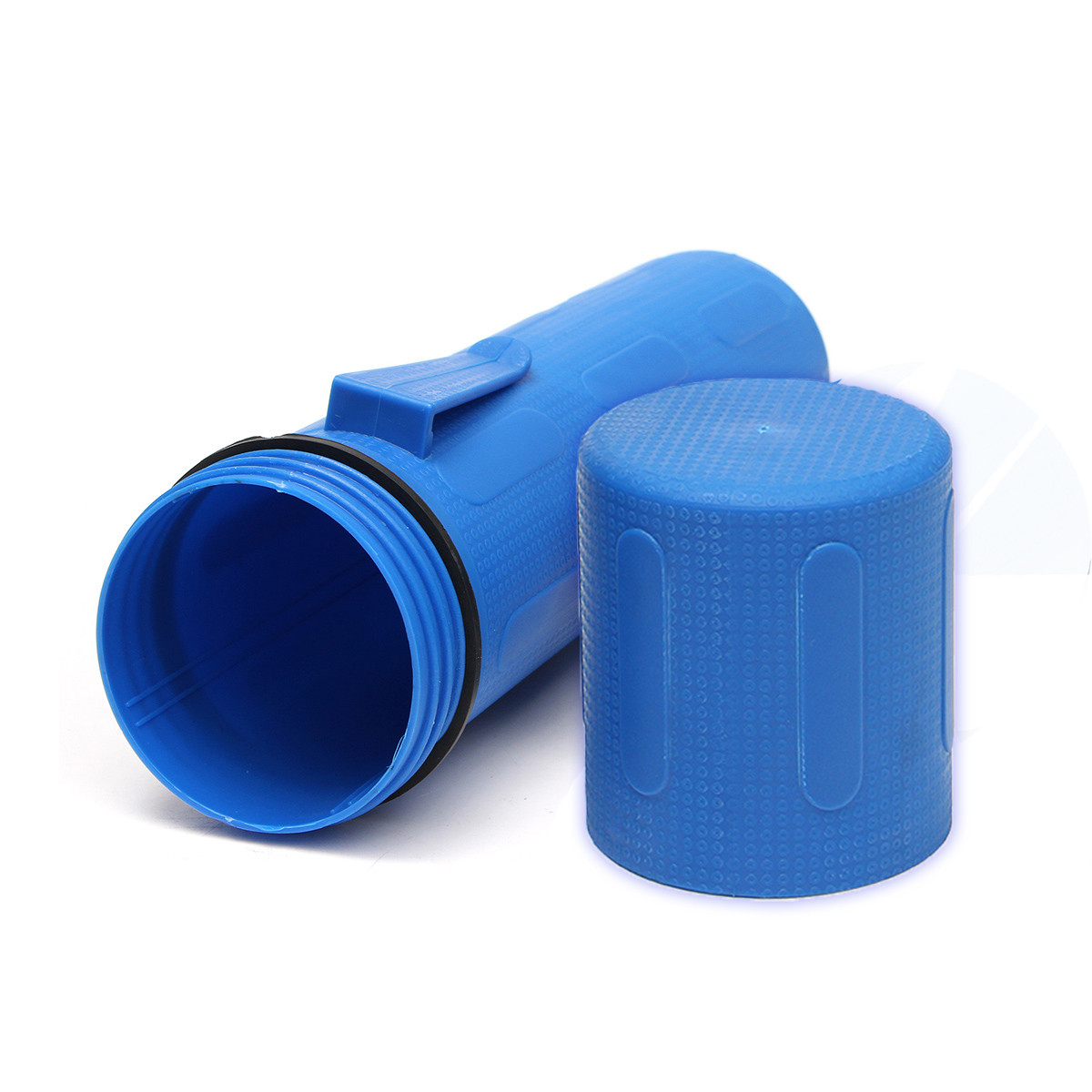

Liquid Weld is a two-part epoxy system that uses advanced technology to create an unbreakable bond between aluminum surfaces. The kit includes a resin and an activator, which are mixed together before application. Once applied, Liquid Weld forms a strong and permanent seal that resists cracking, peeling, or breaking.

The Magic Behind Liquid Weld

The secret to Liquid Weld’s extraordinary strength lies in its unique formula. The resin is made up of high-strength polymers that penetrate the surface of the aluminum, creating a deep and lasting bond. The activator acts as a catalyst, speeding up the curing process and ensuring a quick and effective repair.

Recommended For

Liquid Weld is highly recommended for a vast array of aluminum repair applications, including:

- Automotive repairs (e.g., cracked rims, engine blocks)

- Marine repairs (e.g., boat hulls, propellers)

- Household repairs (e.g., broken appliances, furniture)

- Industrial repairs (e.g., machinery, equipment)

Versatile and Easy to Use

Liquid Weld’s versatility makes it an ideal choice for anyone who works with aluminum. It can be used on a wide range of surfaces, including anodized aluminum, polished aluminum, and even painted aluminum. Plus, its easy-to-use formula requires no special equipment or training. Simply mix the resin and activator, apply it to the damaged area, and let it cure.

Tips for Using Liquid Weld

To ensure optimal results when using Liquid Weld, follow these tips:

- Clean the aluminum surface thoroughly before applying Liquid Weld.

- Mix the resin and activator in a 1:1 ratio.

- Apply a thin layer of Liquid Weld to the damaged area.

- Allow Liquid Weld to cure for at least 24 hours before using the repaired item.

Safety First

When using Liquid Weld, always wear gloves and safety glasses. Avoid contact with skin or eyes, and keep it out of reach of children. If Liquid Weld comes into contact with skin, rinse immediately with water.

Fun Facts About Liquid Weld

Did you know that Liquid Weld:

- Can create a bond that is stronger than the original aluminum.

- Is resistant to extreme temperatures, chemicals, and corrosion.

- Can be used to repair both indoor and outdoor items.

How to Repair Aluminum with Liquid Weld

Here’s a step-by-step guide on how to repair aluminum with Liquid Weld:

- Clean the damaged area with a degreaser.

- Mix the resin and activator in a 1:1 ratio.

- Apply a thin layer of Liquid Weld to the damaged area.

- Clamp the repaired area together.

- Allow Liquid Weld to cure for at least 24 hours before using the repaired item.

What if Liquid Weld Doesn’t Work?

In the unlikely event that Liquid Weld doesn’t work for you, there may be a few reasons why:

- The surface was not properly cleaned.

- The resin and activator were not mixed in the correct ratio.

- The Liquid Weld was not applied correctly.

- The repaired item was not allowed to cure for long enough.

Listicle: 10 Amazing Uses for Liquid Weld

Here’s a listicle of 10 amazing uses for Liquid Weld:

- Repair cracked car rims

- Fix leaky plumbing pipes

- Mend broken appliances

- Seal cracks in aluminum boats

- Repair damaged lawn furniture

- Fix broken aluminum toys

- Restore vintage aluminum items

- Create custom aluminum jewelry

- Make aluminum sculptures

- Repair aluminum siding

Q&A:

Q: Is Liquid Weld safe to use on all aluminum surfaces?

A: Yes, Liquid Weld is safe to use on all aluminum surfaces, including anodized aluminum, polished aluminum, and painted aluminum.

Q: How long does Liquid Weld take to cure?

A: Liquid Weld takes approximately 24 hours to cure completely. However, it is recommended to wait at least 48 hours before using the repaired item.

Q: Can I use Liquid Weld to repair aluminum that is exposed to extreme temperatures?

A: Yes, Liquid Weld is resistant to extreme temperatures, making it ideal for repairs on items that are exposed to high or low temperatures.

Q: How strong is the bond created by Liquid Weld?

A: Liquid Weld creates a bond that is stronger than the original aluminum, ensuring a durable and long-lasting repair.

Conclusion of Aluminum Repair Revolution: Liquid Weld For Quick And Effective Aluminum Fixes

Liquid Weld is truly a game-changer in the world of aluminum repair. Its revolutionary formula and ease of use make it an essential tool for anyone who works with aluminum. Whether you’re a professional mechanic, a DIY enthusiast, or simply someone who wants to fix their favorite aluminum item, Liquid Weld has got you covered. With its quick and effective repairs, you can say goodbye to costly and time-consuming traditional repair methods. Embrace the aluminum repair revolution today and experience the power of Liquid Weld!