An enigmatic malfunction lurks within the heart of your engine, causing a symphony of shudder and unease. The culprit? The harmonic balancer, an unsung hero now become a source of torment. Join us as we delve into the depths of this automotive conundrum, uncovering its root causes and unraveling its enigmatic secrets.

The Agony of a Rough Idle

A rough idle is an unsettling experience, a relentless vibration that shakes your vehicle to its core. It’s not just a nuisance, it’s a symptom of a deeper issue, a cry for help from your engine. The harmonic balancer, a crucial component in the engine’s symphony, may be the conductor of this disharmony.

The Cunning Culprit

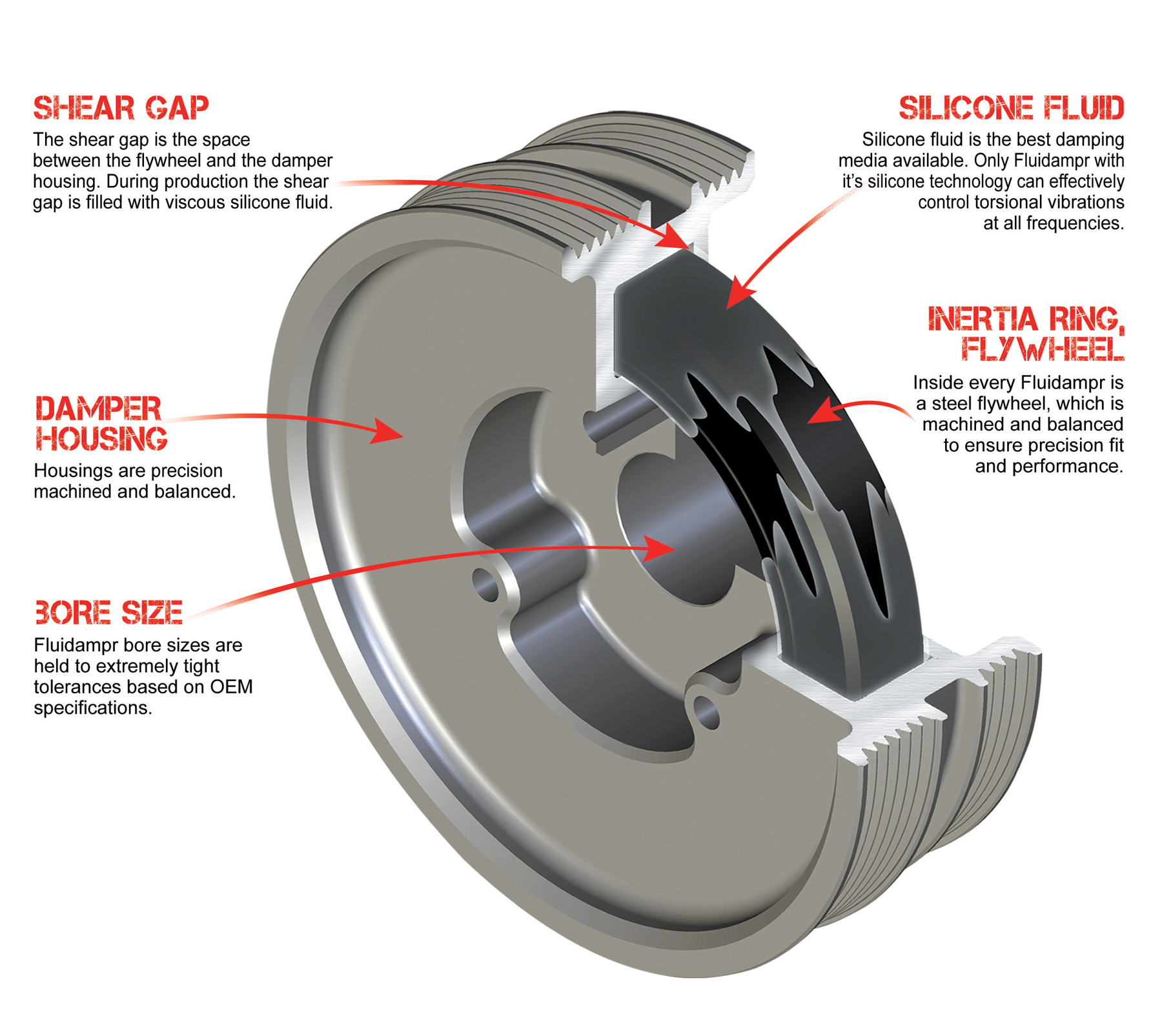

The harmonic balancer, a deceptively simple ring encircling the crankshaft, plays a vital role in maintaining engine stability. It absorbs anddampens vibrations caused by the pistons’ relentless dance. When this balancer falters, its ability to tame these vibrations is compromised, leading to the telltale rough idle.

Peering into the Engine’s Depths: Harmonic Balancer Malfunction

A harmonic balancer malfunction can stem from various ailments. Material fatigue, excessive wear, or a faulty installation can all disrupt its delicate balance, causing it to succumb to the relentless forces at play within the engine.

Material Fatigue: A Silent Nemesis

Over time, the constant vibrations and heat can take their toll on the harmonic balancer’s material. Cracks or deformations can develop, weakening its structure and compromising its ability to absorb vibrations. This insidious process often goes unnoticed until it manifests as a rough idle.

Excessive Wear: The Grind of Time

Grinding against the crankshaft pulley, the harmonic balancer endures constant friction. Over time, this friction can lead to excessive wear, reducing its diameter and diminishing its effectiveness in dampening vibrations.

Faulty Installation: A Misaligned Symphony

Improper installation can disrupt the harmonic balancer’s delicate balance. If it is not properly aligned with the crankshaft, it will fail to absorb vibrations effectively, resulting in a rough idle and potentially more severe engine damage.

The History and Myths of Harmonic Balancer Malfunctions

Harmonic balancers have a long and winding history, dating back to the early days of internal combustion engines. Over the years, various myths and misconceptions have surrounded these enigmatic components:

Myth 1: Harmonic Balancers Are Only Found in High-Performance Engines

This is not true. Harmonic balancers are essential components in all internal combustion engines, regardless of their performance level. They play a crucial role in reducing vibrations and maintaining engine stability.

Myth 2: Harmonic Balancer Malfunctions Are Always Detectable

While some harmonic balancer malfunctions produce noticeable symptoms like a rough idle, others can be more subtle and difficult to detect. Regular inspections and proactive maintenance are crucial to identify and address these hidden issues.

Unveiling the Hidden Secrets of Harmonic Balancer Malfunctions

Beyond the obvious symptoms and common causes, harmonic balancer malfunctions can manifest in various ways, each holding its own unique significance:

Belt Squealing: A Harbinger of Trouble

A squealing serpentine belt can be a sign of an underlying harmonic balancer malfunction. As the balancer wobbles or moves out of alignment, it can cause the belt to slip, producing a high-pitched squeal.

Oil Leaks: A Telltale Sign

Harmonic balancer malfunctions can sometimes cause oil leaks. As the balancer seal deteriorates or becomes damaged, oil can seep out, leaving telltale drops beneath your vehicle.

Engine Misfires: A Disturbance in Harmony

A malfunctioning harmonic balancer can disrupt the engine’s timing, leading to misfires. These misfires can cause the engine to run rough, hesitate, and lose power.

Recommendations for Preventing and Resolving Harmonic Balancer Malfunctions

To maintain a healthy harmonic balancer and prevent costly repairs, consider these recommendations:

Regular Inspections: A Proactive Approach

Regularly inspect your harmonic balancer for any signs of damage, such as cracks, deformations, or excessive wear. Early detection and prompt repairs can prevent minor issues from escalating into major problems.

Proper Installation: The Key to Longevity

Ensure that your harmonic balancer is properly installed by a qualified mechanic. Correct alignment and torque specifications are crucial for its optimal performance and longevity.

Quality Components: Investing in Reliability

When replacing a harmonic balancer, opt for high-quality components from reputable manufacturers. Inferior parts may compromise your engine’s stability and lead to premature failure.

Harmonic Balancer Malfunction: Diagnosis and Troubleshooting

Diagnosing and troubleshooting a harmonic balancer malfunction requires a comprehensive approach:

Visual Inspection: The Starting Point

Begin by visually inspecting the harmonic balancer for any visible damage, such as cracks, deformations, or excessive wear. A flashlight and a mirror can aid in examining hard-to-reach areas.

Vibration Analysis: Quantifying the Issue

Utilize vibration analysis tools, such as a dial indicator or a vibration analyzer, to measure the amount of vibration produced by the harmonic balancer. Excessive vibration levels indicate a potential malfunction.

Timing Analysis: Checking the Rhythm

Perform timing analysis to check if the harmonic balancer is causing timing issues. A timing light will reveal any deviations from the specified timing values, which can be caused by a faulty harmonic balancer.

Tips for Avoiding Harmonic Balancer Malfunctions

A few simple precautions can go a long way in preventing harmonic balancer malfunctions:

Regular Maintenance: A Stitch in Time

Regular maintenance, including oil changes and inspections, can help detect and address potential issues before they escalate into major problems. Timely repairs can significantly reduce the risk of harmonic balancer malfunctions.

Avoid Excessive Engine Revving

Avoid revving your engine excessively, especially when it is cold. High engine speeds can put undue stress on the harmonic balancer, leading to premature wear and failure.

Use Quality Engine Oil

Using high-quality engine oil helps to reduce friction and wear on the harmonic balancer and other engine components. Choose oils that meet the manufacturer’s specified viscosity and performance standards.

Harmonic Balancer Malfunction: Signs and Symptoms

A malfunctioning harmonic balancer can manifest through various signs and symptoms, including:

Rough Idle: The Telltale Sign

A rough idle, characterized by excessive shaking or vibration at low engine speeds, is a common symptom of a harmonic balancer malfunction.

Belt Squealing: A Warning Cry

A squealing serpentine belt can indicate a misaligned or damaged harmonic balancer, causing the belt to slip and produce a high-pitched noise.

Oil Leaks: A Silent Troublemaker

Oil leaks around the harmonic balancer area can signal a damaged seal, allowing oil to seep out and potentially contaminate other engine components.

Fun Facts about Harmonic Balancer Malfunctions

Here are some intriguing fun facts about harmonic balancer malfunctions:

The Importance of Torsional Stiffness

The harmonic balancer’s torsional stiffness plays a crucial role in dampening vibrations. A balancer with the correct stiffness will effectively absorb and dissipate harmful vibrations, reducing engine noise and improving overall performance.

The Role of Damping Material

Many harmonic balancers incorporate damping material, such as rubber, to further reduce vibrations. This material helps to absorb and dissipate energy, preventing it from being transmitted to other engine components.

The Impact on Fuel Efficiency

A malfunctioning harmonic balancer can negatively impact fuel efficiency. Excessive vibrations can increase engine friction, leading to higher fuel consumption and reduced overall performance.

How to Replace a Harmonic Balancer

Replacing a harmonic balancer requires specialized tools and knowledge:

Safety First: Essential Precautions

Before attempting any repairs, ensure your vehicle is properly secured and the engine is cool. Wear appropriate safety gear, including gloves and eye protection.

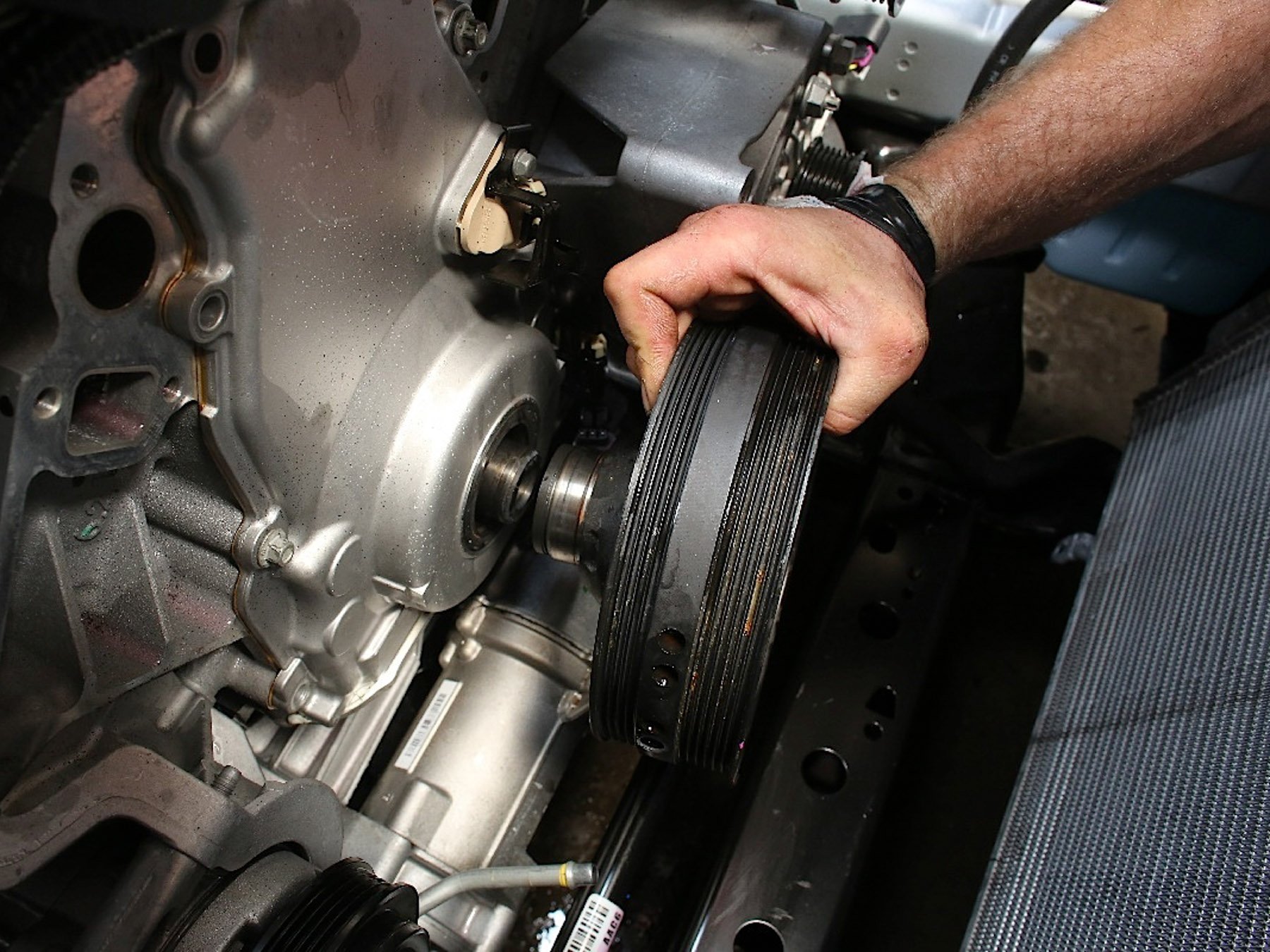

Removing the Serpentine Belt

Locate and loosen the serpentine belt tensioner to remove the serpentine belt. Refer to your vehicle’s service manual for the specific steps.

Unbolting the Harmonic Balancer

Using a harmonic balancer puller, carefully unbolt the harmonic balancer from the crankshaft. Be cautious not to damage the crankshaft or the threads on the balancer.

Installing the New Balancer

Align the new harmonic balancer with the crankshaft and carefully tighten the bolts to the specified torque. Ensure proper alignment to prevent future issues.

What If I Ignore a Harmonic Balancer Malfunction?

Ignoring a harmonic balancer malfunction can lead to severe consequences:

Accelerated Engine Wear

Excessive vibrations can accelerate wear on other engine components, such as bearings, pistons, and valves, leading to costly repairs.