Have you ever wondered about the intricate components that keep your engine running smoothly? One crucial aspect is the oil system, responsible for lubricating and protecting the moving parts within. When oil system components fail, it can have devastating consequences for your engine.

Consequences of Oil System Component Failure

Oil system component failure can lead to a range of issues, from minor inconveniences to catastrophic engine damage. A malfunctioning oil pump may not provide adequate lubrication, causing bearings and other components to grind against each other. Leaky gaskets or seals can allow oil to leak out, reducing oil pressure and potentially leading to overheating.

Target of Oil System Component Failure

Oil system component failure can affect various engine components, including bearings, pistons, camshafts, and valves. Without proper lubrication, these components face increased friction, wear, and tear, eventually leading to premature failure.

Summary of Oil System Component Failure

In summary, oil system component failure is a serious issue that can result in significant engine damage. It can affect multiple engine components and lead to reduced oil pressure, overheating, and premature failure of critical parts. Therefore, it is crucial to address oil system issues promptly to ensure the longevity and reliability of your engine.

Target of Oil System Component Failure

The primary target of Oil System Component Failure is the engine. Without proper lubrication, various engine components, such as bearings, pistons, camshafts, and valves, can experience increased friction, wear and tear, eventually leading to premature failure.

Oil System Component Failure can also affect other critical engine systems. For instance, a faulty oil pump can lead to reduced oil pressure, which can in turn result in overheating and damage to other engine components.

What is Oil System Component Failure?

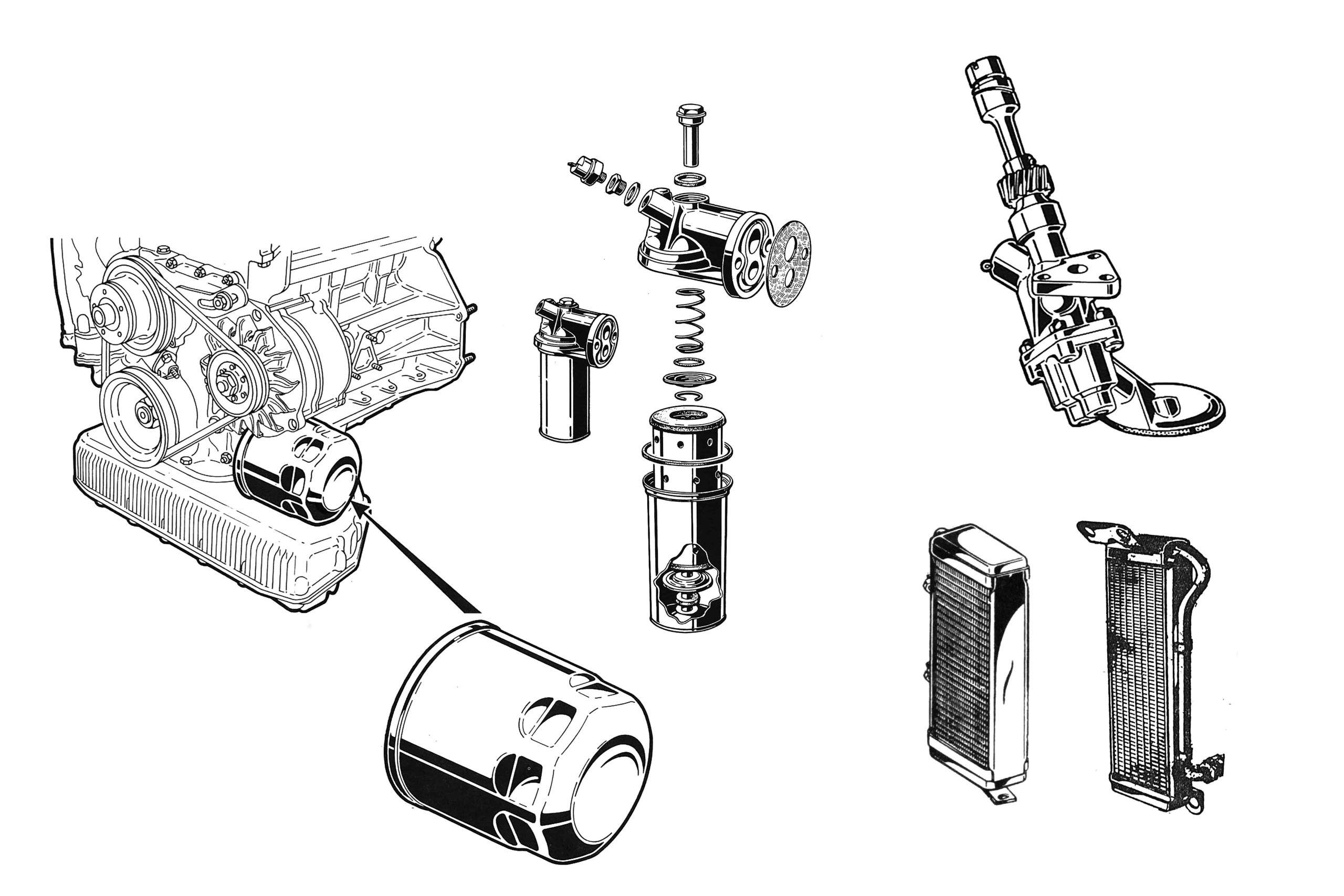

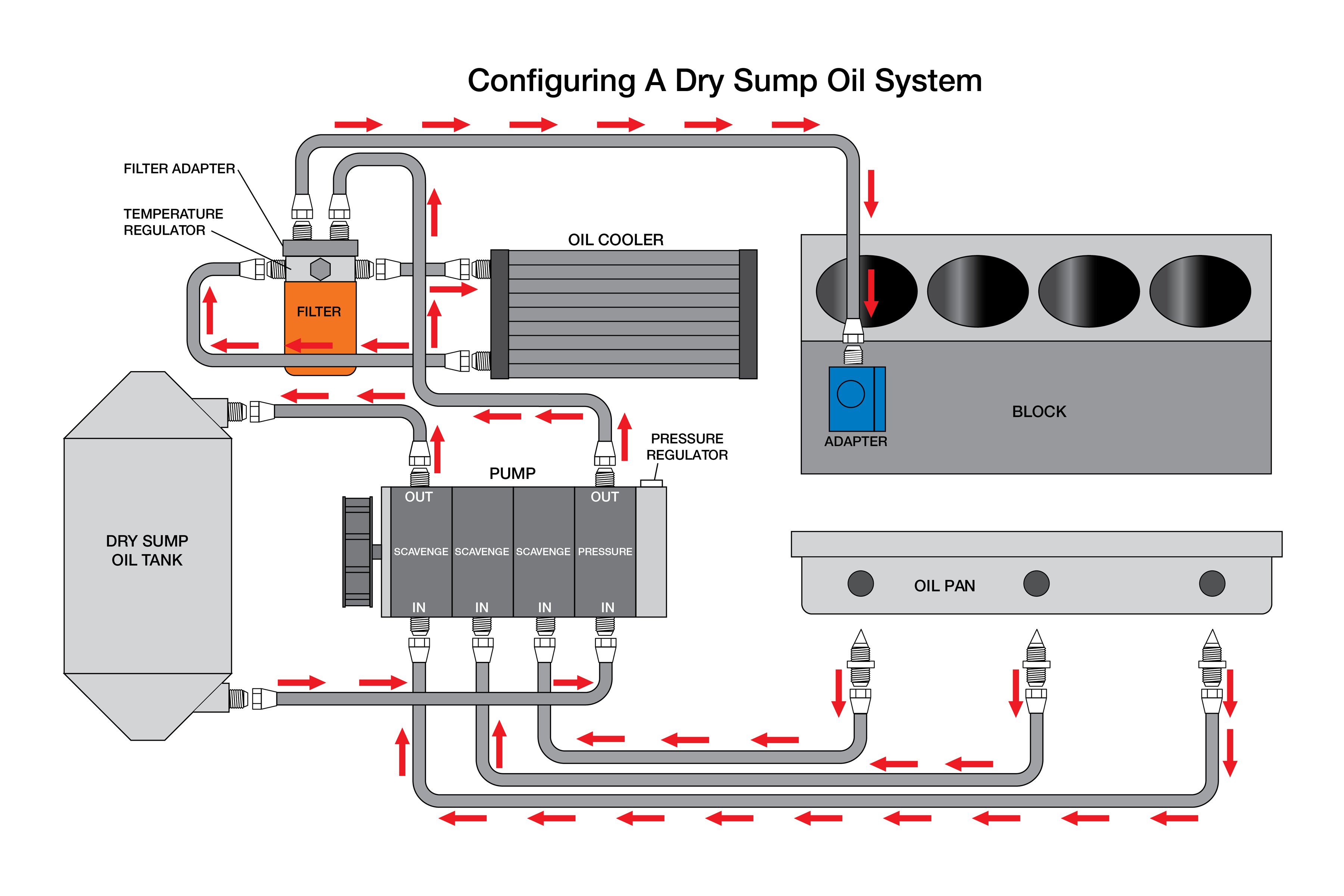

Oil System Component Failure refers to the malfunction or failure of any component within the oil system, which is responsible for lubricating and protecting engine parts. This can include issues with the oil pump, oil filter, oil pan, gaskets, and seals.

When an oil system component fails, it can disrupt the normal flow and distribution of oil throughout the engine. This can result in a lack of lubrication, increased friction, and excessive wear and tear on engine components.

History and Myth of Oil System Component Failure

The history of Oil System Component Failure can be traced back to the early days of internal combustion engines. In the past, engine oil systems were less sophisticated and prone to failures, leading to frequent engine breakdowns.

Over time, advancements in engine design and the development of more durable oil system components have significantly reduced the incidence of Oil System Component Failure. However, it remains a potential issue in modern engines, especially if proper maintenance and care are neglected.

Hidden Secret of Oil System Component Failure

One of the lesser-known secrets of Oil System Component Failure is that it can often be prevented through proper engine maintenance. Regular oil changes and filter replacements ensure that the oil system remains clean and free of contaminants.

Additionally, using high-quality engine oil and avoiding overloading the engine can help extend the lifespan of oil system components and reduce the risk of premature failure.

Recommendation of Oil System Component Failure

To prevent Oil System Component Failure and ensure the longevity of your engine, follow these recommendations:

- Perform regular oil changes as per the manufacturer’s recommended intervals.

- Use high-quality engine oil that meets the specifications of your engine.

- Replace the oil filter every time you change the oil.

- Avoid overloading the engine by exceeding its load capacity.

- Have your engine inspected by a qualified mechanic if you suspect any issues with the oil system.

Oil System Component Failure Prevention Tips

In addition to regular maintenance, here are some tips to further reduce the risk of Oil System Component Failure:

- Monitor the oil level regularly and add oil as needed.

- Be aware of any unusual noises or vibrations coming from the engine.

- Check for leaks or drips under the engine.

- Avoid using aftermarket oil filters that do not meet the manufacturer’s specifications.

Related Keywords for Oil System Component Failure

Fun Facts of Oil System Component Failure

Here are some interesting facts about Oil System Component Failure:

- Oil System Component Failure is a major cause of engine breakdowns, especially in older vehicles.

- The oil pump is the heart of the oil system and can fail due to wear, corrosion, or contamination.

- A clogged oil filter can starve the engine of oil, leading to rapid wear and tear.

- Oil leaks can develop in various places, including the oil pan, gaskets, and seals.

How to Avoid Oil System Component Failure

To avoid Oil System Component Failure, follow these steps:

- Maintain a regular oil change schedule.

- Use high-quality engine oil and filters.

- Check the oil level regularly and add oil as needed.

- Inspect the engine for leaks or drips.

- Be aware of any unusual noises or vibrations coming from the engine.

What if Oil System Component Failure Occurs?

If you suspect Oil System Component Failure, take the following steps:

- Stop driving the vehicle immediately.

- Have the vehicle towed to a qualified mechanic.

- The mechanic will diagnose the issue and replace the failed component.

Listicle of Oil System Component Failure

Here is a listicle summarizing the key points about Oil System Component Failure:

- Oil System Component Failure is a serious issue that can lead to engine damage.

- Regular maintenance is essential to prevent Oil System Component Failure.

- Common causes of Oil System Component Failure include oil pump failure, oil filter clogging, and oil leaks.

- If you suspect Oil System Component Failure, stop driving the vehicle immediately and have it towed to a mechanic.

Questions and Answers about Oil System Component Failure

- Q: What are the common symptoms of Oil System Component Failure?

A: Symptoms include low oil pressure, oil leaks, and unusual noises or vibrations from the engine.

- Q: What are the most likely causes of Oil System Component Failure?

A: Common causes include oil pump failure, oil filter clogging, and oil leaks due to worn or damaged gaskets and seals.

- Q: Can Oil System Component Failure be prevented?

A: Yes, regular maintenance, including oil changes, filter replacements, and inspections, can help prevent Oil System Component Failure.

- Q: What should I do if I suspect Oil System Component Failure?

A: If you suspect Oil System Component Failure, stop driving the vehicle immediately and have it towed to a qualified mechanic for diagnosis and repair.

Conclusion of Oil System Component Failure

Oil System Component Failure is a serious issue that can lead to significant engine damage. By understanding the causes, symptoms, and prevention methods, you can help ensure the longevity and reliability of your vehicle’s engine.