Have you ever felt the frustration of your car not starting and not knowing why? It could be due to a faulty crank sensor. In this article, we will delve into the purpose of a crank sensor, its history, and how to identify and resolve issues related to it.

Understanding the Importance of a Crank Sensor

A crank sensor plays a crucial role in the proper functioning of your vehicle. It monitors the position and speed of the crankshaft, which is essential for the engine’s timing and ignition systems. A faulty crank sensor can lead to various problems, including engine stalling, difficulty starting, and reduced fuel efficiency.

Purpose of a Crank Sensor

The primary purpose of a crank sensor is to detect the position of the crankshaft and transmit this information to the engine’s electronic control unit (ECU). The ECU uses this input to determine the timing of fuel injection and spark ignition, ensuring optimal engine performance.

Different Types of Crank Sensors

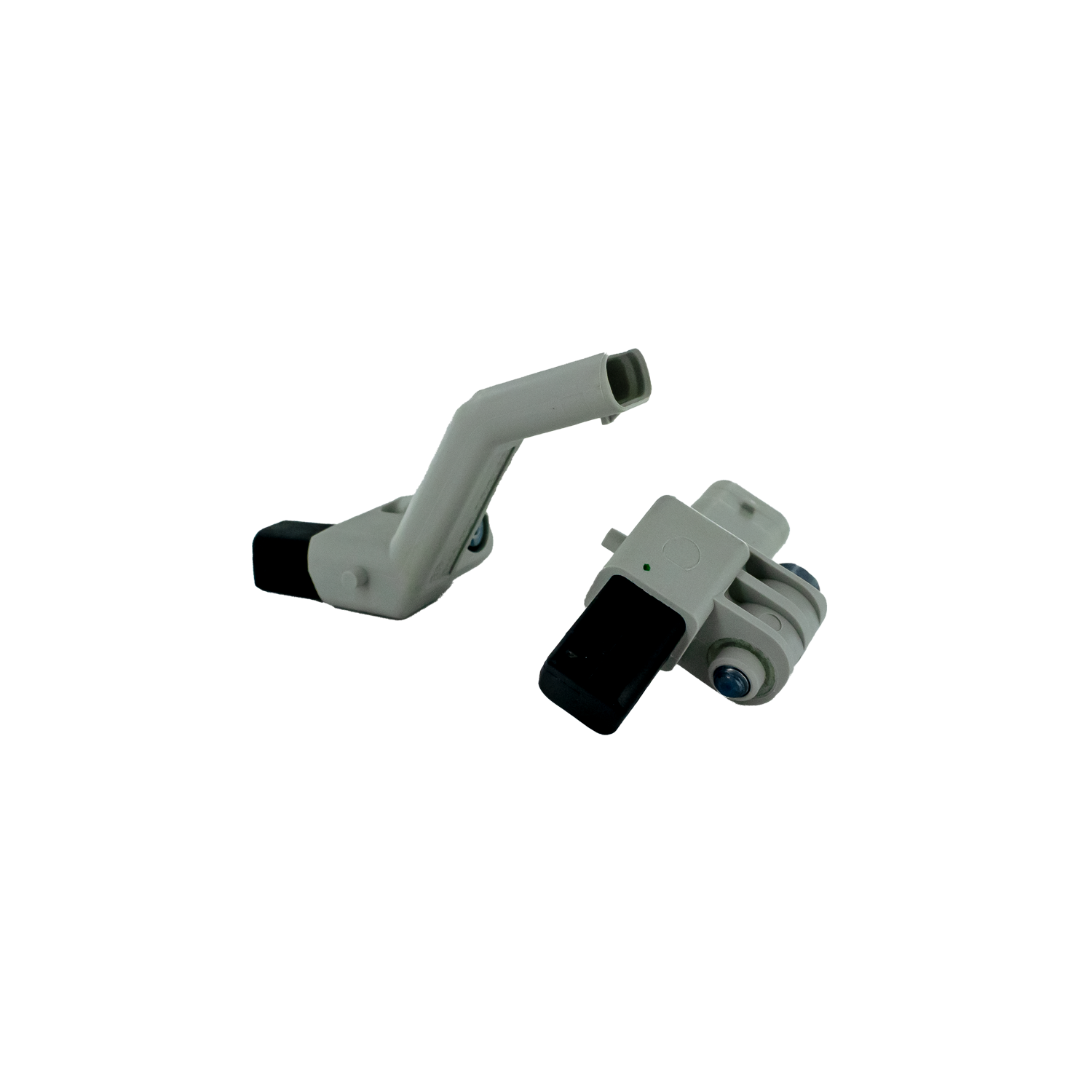

Magnetic Crank Sensor

This type of sensor uses a magnetic field to detect the teeth on the crankshaft’s flywheel. As the flywheel rotates, the teeth pass through the magnetic field, generating an electrical signal that is sent to the ECU.

Inductive Crank Sensor

Inductive crank sensors operate on the principle of electromagnetic induction. As the crankshaft rotates, the teeth on the flywheel create a magnetic field that induces an electrical current in the sensor’s coil. The strength of the current varies with the speed of the crankshaft, providing the ECU with information about both the position and speed of the engine.

Signs of a Faulty Crank Sensor

A faulty crank sensor can manifest in various symptoms, including:

- Engine stalling

- Difficulty starting

- Reduced fuel efficiency

- Check engine light illumination

- Intermittent engine operation

Diagnosing and Replacing a Faulty Crank Sensor

Diagnosing a faulty crank sensor requires specialized tools and knowledge. Typically, a mechanic will use an oscilloscope to monitor the sensor’s output signal and determine if it is within the manufacturer’s specifications.

Preventive Maintenance for Crank Sensors

To prevent premature failure of the crank sensor, it is recommended to follow regular maintenance practices, such as:

- Adhering to the manufacturer’s recommended service intervals

- Inspecting the sensor and its wiring harness for damage or corrosion

- Cleaning the sensor and its mounting surface

Conclusion of Purpose Of Crank Sensor

The crank sensor plays a vital role in the proper functioning of a vehicle’s engine. By understanding its purpose and symptoms related to its failure, you can help ensure your car operates at its optimal level.