Is Your Car Cranking but Not Starting? The Crankshaft Sensor Might Be to Blame

If you’re having trouble starting your car, it could be a sign of a faulty crankshaft sensor. This small but important sensor plays a crucial role in ensuring that your engine runs smoothly. Here’s everything you need to know about the purpose of a crankshaft sensor and how it can affect your vehicle.

A crankshaft sensor is a device that monitors the position and speed of the crankshaft. It sends this information to the engine control module (ECM), which uses it to control the timing of the fuel injection and ignition systems. Without a functioning crankshaft sensor, the ECM cannot accurately control these systems, which can lead to a variety of problems, including:

What is the Purpose of a Crankshaft Sensor?

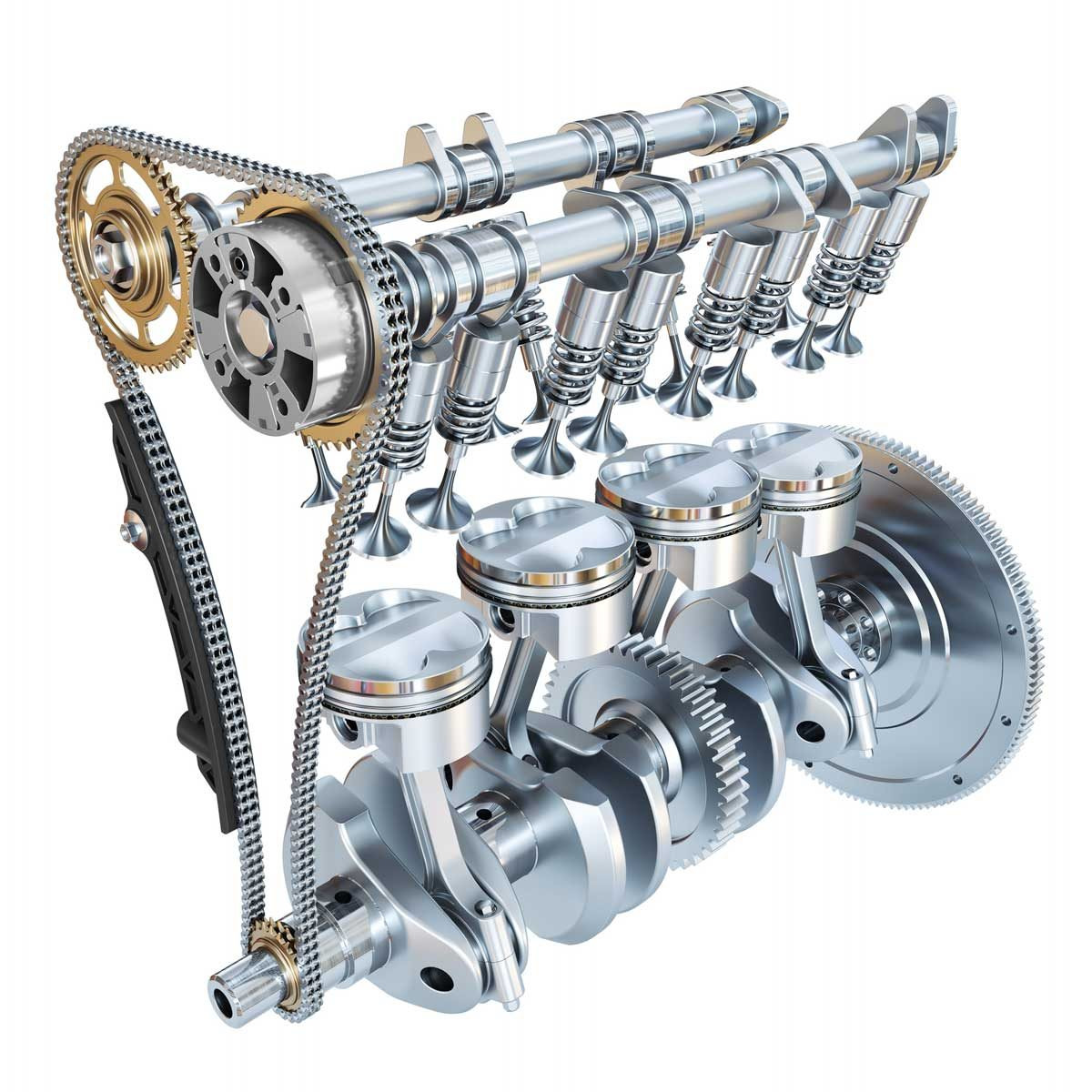

The crankshaft sensor is responsible for detecting the position of the crankshaft and crankshaft speed. It does this by using a reluctor wheel, which is attached to the crankshaft. The reluctor wheel has a series of teeth that pass by the sensor as the crankshaft rotates. The sensor uses these teeth to generate an electrical signal that is sent to the engine control module (ECM). The ECM uses this signal to determine the position of the crankshaft and to calculate the engine speed.

The crankshaft sensor is a critical component of the engine management system. It provides the ECM with information that is essential for controlling the engine’s timing and fuel injection. Without a functioning crankshaft sensor, the engine will not be able to run properly.

Crankshaft sensors have been around for decades, but their design and operation have evolved over time. Early crankshaft sensors were simple inductive sensors that generated a voltage pulse when a metal tooth on the reluctor wheel passed by the sensor. Modern crankshaft sensors are more sophisticated and use a variety of technologies, including Hall effect sensors and optical sensors. These sensors are more accurate and reliable than older inductive sensors.

Hidden Secrets of the Crankshaft Sensor

The crankshaft sensor is a relatively small and unassuming component, but it plays a vital role in the operation of your engine. Here are a few hidden secrets about crankshaft sensors that you may not know:

- Crankshaft sensors are often used in conjunction with camshaft sensors to provide the ECM with information about the timing of the engine’s valves and pistons.

- Crankshaft sensors can be used to detect misfires. If the ECM detects a sudden change in the crankshaft speed, it may indicate that a misfire has occurred.

- Crankshaft sensors can be used to control the engine’s idle speed. The ECM can use the information from the crankshaft sensor to adjust the amount of fuel that is injected into the engine, which can affect the idle speed.

Recommended Crankshaft Sensors for Your Vehicle

If you are experiencing problems with your vehicle’s engine, it is important to have the crankshaft sensor checked. A faulty crankshaft sensor can cause a variety of problems, including:

- Difficulty starting the engine

- Rough idling

- Loss of power

- Stalling

If you suspect that your vehicle’s crankshaft sensor is faulty, it is important to have it replaced as soon as possible. A new crankshaft sensor is relatively inexpensive and easy to replace. Replacing the crankshaft sensor yourself can save you money on labor costs.

Benefits of Replacing a Crankshaft Sensor

Replacing a faulty crankshaft sensor can provide a number of benefits for your vehicle, including:

- Improved engine performance

- Reduced emissions

- Increased fuel efficiency

- Smoother idling

- Fewer stalls

How to Diagnose a Faulty Crankshaft Sensor

If you suspect that your vehicle’s crankshaft sensor is faulty, there are a few things you can do to diagnose the problem. First, check the engine’s trouble codes. A faulty crankshaft sensor will often trigger a trouble code. You can use a code reader to retrieve the trouble codes from your vehicle’s computer.

If you do not have a code reader, you can also try to diagnose the problem by observing the engine’s symptoms. A faulty crankshaft sensor can cause a variety of symptoms, including:

- Difficulty starting the engine

- Rough idling

- Loss of power

- Stalling

If you are experiencing any of these symptoms, it is possible that your vehicle’s crankshaft sensor is faulty.

Tips for Maintaining Your Crankshaft Sensor

The crankshaft sensor is a critical component of your vehicle’s engine, so it is important to keep it in good condition. Here are a few tips for maintaining your crankshaft sensor:

- Keep the engine oil clean and at the proper level.

- Inspect the crankshaft sensor for damage or wear.

- Replace the crankshaft sensor if it is faulty.

By following these tips, you can help to ensure that your crankshaft sensor lasts for many years to come.

Fun Facts About Crankshaft Sensors

Here are a few fun facts about crankshaft sensors:

- Crankshaft sensors were first used in the early 1980s.

- Crankshaft sensors are used in both gasoline and diesel engines.

- Crankshaft sensors are typically located near the crankshaft.

How to Replace a Crankshaft Sensor

Replacing a crankshaft sensor is a relatively simple task that can be completed in about an hour. Here are the steps on how to replace a crankshaft sensor:

- Disconnect the negative battery terminal.

- Locate the crankshaft sensor. It is typically located near the crankshaft.

- Unplug the electrical connector from the crankshaft sensor.

- Remove the bolts that hold the crankshaft sensor in place.

- Remove the old crankshaft sensor and install the new crankshaft sensor.

- Tighten the bolts that hold the crankshaft sensor in place.

- Plug the electrical connector into the crankshaft sensor.

- Reconnect the negative battery terminal.

Once you have replaced the crankshaft sensor, start the engine and check for any problems.

What Happens if My Crankshaft Sensor Fails?

If your crankshaft sensor fails, your vehicle will not be able to start. The crankshaft sensor is responsible for sending a signal to the engine’s computer, which tells the computer when to fire the spark plugs and inject fuel. Without a functioning crankshaft sensor, the engine will not know when to fire the spark plugs and inject fuel, and it will not be able to start.

In addition to preventing your vehicle from starting, a faulty crankshaft sensor can also cause a number of other problems, including:

- Rough idling

- Loss of power

- Stalling

If you are experiencing any of these problems, it is important to have your crankshaft sensor checked by a qualified mechanic.

Listicle: 5 Signs of a Faulty Crankshaft Sensor

Here is a listicle of five signs that your crankshaft sensor may be faulty:

- Difficulty starting the engine

- Rough idling

- Loss of power

- Stalling

- Check engine light is on

If you are experiencing any of these problems, it is important to have your crankshaft sensor checked by a qualified mechanic.

Question and Answer

- What is the purpose of a crankshaft sensor?

- What are the symptoms of a faulty crankshaft sensor?

- How do I replace a crankshaft sensor?

A crankshaft sensor is responsible for detecting the position of the crankshaft and crankshaft speed. It sends this information to the engine control module (ECM), which uses it to control the timing of the fuel injection and ignition systems.

The symptoms of a faulty crankshaft sensor can include difficulty starting the engine, rough idling, loss of power, and stalling.

Replacing a crankshaft sensor is a relatively simple task that can be completed in about an hour.