Optimizing power transmission is vital for efficient and reliable operation of machinery. V belts and pulleys play a crucial role in this process, ensuring smooth and efficient power transfer.

Inefficient power transmission can lead to wasted energy, increased maintenance costs, and premature equipment failure. To address these challenges, optimizing the use of V belts and pulleys is essential.

7. Optimizing Power Transmission With V Belts And Pulleys

Optimizing power transmission with V belts and pulleys involves selecting the right components, considering design factors, and implementing proper maintenance practices. By following these principles, businesses can improve equipment performance, reduce downtime, and save costs.

Power Transmission with V Belts and Pulleys

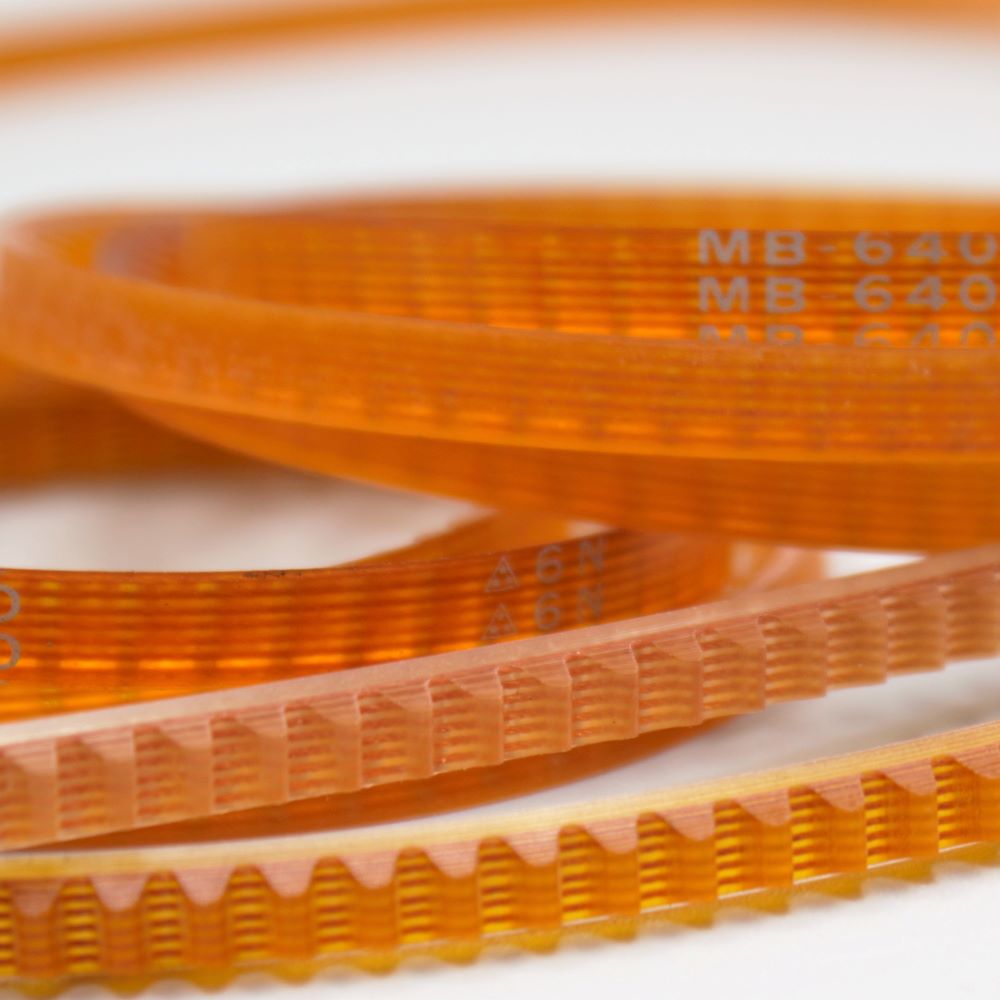

V belts are trapezoidal-shaped belts that fit into grooved pulleys. They are designed to transmit power from one shaft to another, providing a positive drive. Optimizing this power transmission involves selecting the correct belt size and profile, choosing the appropriate pulley diameters, and aligning the components properly.

History and Myth of V Belts and Pulleys

V belts and pulleys have a rich history, dating back to the early days of industrial machinery. Over time, myths and misconceptions have arisen around their use. By understanding the true nature of these components, businesses can dispel these myths and optimize power transmission.

Hidden Secrets of V Belts and Pulleys

Optimizing power transmission often involves uncovering hidden secrets of V belts and pulleys. These secrets relate to factors such as belt tension, pulley alignment, and lubrication. By understanding these hidden secrets and implementing appropriate measures, businesses can ensure efficient and reliable power transmission.

Recommendations for V Belts and Pulleys

There are several recommendations to consider when optimizing power transmission with V belts and pulleys. These include selecting belts with the correct length and tension, using high-quality pulleys, aligning components properly, and following recommended maintenance practices.

Tips for Optimizing Power Transmission

To further optimize power transmission, businesses can adhere to specific tips. These tips include using anti-static belts to reduce electrical discharge, considering the ambient temperature and humidity, and avoiding overloading the belts. By implementing these tips, businesses can minimize friction, prevent premature wear, and extend the lifespan of their power transmission systems.

Fun Facts about V Belts and Pulleys

V belts and pulleys have some interesting fun facts associated with them. These include their use in a wide range of industries, their contribution to energy conservation, and their ability to handle high shock loads. By exploring these fun facts, businesses can gain a deeper appreciation for the role of V belts and pulleys in power transmission.

How to Optimize Power Transmission

Optimizing power transmission with V belts and pulleys involves a systematic approach. This approach includes assessing the existing system, identifying areas for improvement, and implementing effective measures. By following these steps, businesses can achieve optimal power transmission and maximize the efficiency of their machinery.

What if Power Transmission is not Optimized?

If power transmission is not optimized, businesses may face a range of negative consequences. These consequences may include increased energy consumption, reduced productivity, excessive maintenance costs, and potential equipment damage. By addressing power transmission optimization, businesses can mitigate these risks and ensure the smooth operation of their equipment.

Listicle of Power Transmission Optimization Techniques

To aid in optimizing power transmission, businesses can refer to a comprehensive listicle of techniques. This listicle may include steps such as selecting the right belt and pulley combination, ensuring proper belt tension, aligning components precisely, and implementing a regular maintenance schedule. By following this listicle, businesses can effectively improve the performance of their power transmission systems.

Question and Answer

Q: How do I know if my power transmission system needs optimization?

A: Signs of a system in need of optimization include excessive noise, vibration, or slippage during operation.

Q: What is the most important factor to consider when optimizing power transmission?

A: Selecting the right belt and pulley combination is crucial, as it impacts power transmission efficiency and durability.

Q: How can I troubleshoot power transmission issues?

A: Common troubleshooting steps involve checking belt tension, inspecting pulleys for wear, and ensuring proper alignment.

Q: What are the benefits of optimizing power transmission?

A: Optimization leads to increased efficiency, reduced energy consumption, improved equipment performance, and extended component lifespan.

Conclusion of 7. Optimizing Power Transmission With V Belts And Pulleys

Optimizing power transmission with V belts and pulleys is a critical aspect of maintaining efficient and reliable machinery operation. By understanding the principles and techniques involved, businesses can effectively improve power transmission, maximize equipment performance, reduce costs, and ensure the smooth operation of their systems.