Are you experiencing dimming lights, sluggish engine performance, or unexplained battery drain? It could be a sign of a loose alternator pulley, and it’s crucial to address it promptly to avoid further issues.

Understanding the Consequences

A loose alternator pulley can lead to a variety of problems, including power fluctuations, charging system failures, and even engine damage. The alternator, responsible for generating electricity for the vehicle’s electrical system, relies on the pulley to maintain proper tension on the serpentine belt. When the pulley is loose, it can cause the belt to slip or jump, disrupting the alternator’s ability to charge the battery efficiently.

Fortunately, tightening the alternator pulley is a relatively simple task that can be performed at home with the right tools and know-how.

Fixing the Issue: A Step-by-Step Guide

Materials:

- Socket wrench

- Ratchet

- 15mm socket

- 13mm socket

Steps:

- Park the vehicle on a flat surface and engage the parking brake.

- Locate the alternator, usually situated on the front of the engine.

- Use the 15mm socket and ratchet to loosen the alternator mounting bolt.

- Use the 13mm socket and ratchet to tighten the alternator pulley bolt until it is snug.

- Tighten the alternator mounting bolt securely.

- Double-check the tightness of both bolts.

What is an Alternator Pulley?

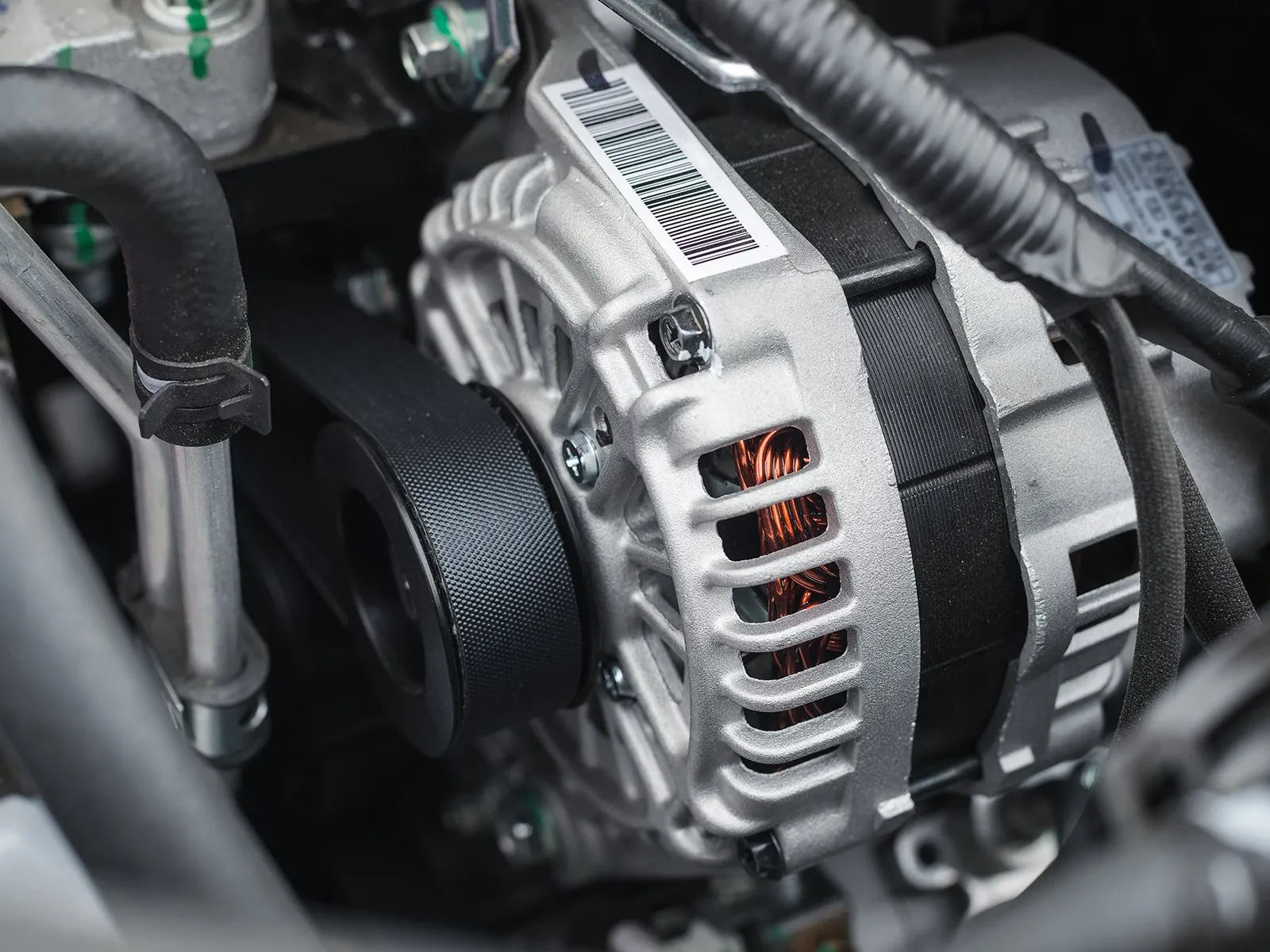

The alternator pulley is a critical component of the vehicle’s charging system, responsible for transferring power from the alternator to the serpentine belt. This belt, in turn, drives various accessories such as the power steering pump, AC compressor, and water pump.

The alternator pulley is typically made of aluminum or steel and has a series of grooves or ribs that engage with the serpentine belt’s teeth. When the alternator is operating correctly, the pulley rotates smoothly, providing the necessary tension to keep the belt from slipping.

Historical Evolution of the Alternator Pulley

The alternator pulley has undergone several evolutionary changes throughout automotive history. In the early days of automobiles, generators were used instead of alternators, and these generators used a different type of pulley.

With the advent of alternators in the mid-20th century, the alternator pulley also evolved to accommodate the new technology. These pulleys were initially made from cast iron, but as vehicles became more sophisticated, lighter and more durable materials like aluminum became the preferred choice.

Unveiling the Hidden Secrets of the Alternator Pulley

While the alternator pulley may seem like a simple component, it plays a vital role in the vehicle’s electrical system. Understanding its hidden secrets can help you diagnose and resolve issues related to the charging system more effectively.

One of the most common problems associated with the alternator pulley is misalignment. This can occur due to factors such as wear, improper installation, or impact damage. Misalignment can lead to premature belt wear, reduced charging efficiency, and even damage to the alternator itself.

Recommended Maintenance and Troubleshooting

Regular maintenance and inspections of the alternator pulley can help prevent unexpected issues. It’s recommended to check the tension of the serpentine belt and the tightness of the pulley bolts at least once a year.

If you notice any symptoms of a loose alternator pulley, such as dimming lights, erratic battery readings, or a squealing noise from the belt, it’s important to address the issue promptly. Neglecting to do so can lead to more severe problems and costly repairs.

Tips for Optimal Pulley Performance

Here are a few tips to help you maintain optimal performance of your alternator pulley:

- Use a high-quality serpentine belt.

- Inspect the pulley for signs of wear or damage.

- Tighten the pulley bolts to the manufacturer’s specifications.

- Avoid using excessive force when tightening the bolts.

Fun Facts: The Lighter Side of Alternator Pulleys

Did you know that the average alternator pulley weighs less than a pound? Despite its small size, it plays a crucial role in the overall performance of the vehicle.

In some high-performance vehicles, lightweight aluminum pulleys are used to reduce rotational inertia and improve acceleration. These pulleys are often anodized in different colors for aesthetic appeal.

DIY Versus Professional Repair: Making an Informed Decision

While tightening the alternator pulley is a relatively simple task, it’s important to assess your skill level and the complexity of the issue before attempting the repair yourself.

If you are uncomfortable working on your vehicle, it’s advisable to consult a qualified mechanic. They have the proper tools, experience, and knowledge to diagnose and repair alternator pulley problems efficiently and accurately.

What If: Exploring the Consequences of Neglect

Ignoring a loose alternator pulley can lead to a range of consequences, including:

- Electrical system failures

- Reduced battery life

- Engine damage

To avoid these costly and inconvenient outcomes, it’s essential to address alternator pulley issues promptly.

Listicle: Essential Know-How for Alternator Pulleys

- The alternator pulley is responsible for transferring power from the alternator to the serpentine belt.

- A loose alternator pulley can cause power fluctuations, charging system failures, and engine damage.

- Tightening an alternator pulley is a relatively simple task that can be performed at home with the right tools.

- Regular maintenance and inspections can help prevent unexpected issues related to the alternator pulley.

- Ignoring a loose alternator pulley can lead to electrical system failures, reduced battery life, and engine damage.

Question and Answer: Resolving Common Queries

- Q: How often should I check the alternator pulley?

A: At least once a year. - Q: What are the symptoms of a loose alternator pulley?

A: Dimming lights, erratic battery readings, and a squealing noise from the belt. - Q: Can I tighten the alternator pulley myself?

A: Yes, if you are comfortable working on your vehicle and have the necessary tools. - Q: What if I tighten the alternator pulley too much?

A: Overtightening can damage the pulley or the alternator itself.

Conclusion of Ultimate Guide: Tightening Your Alternator Pulley For Optimal Performance

By understanding the importance of maintaining a tight alternator pulley, you can help ensure the optimal performance of your vehicle’s charging system. Regular inspections, proper tightening, and timely repairs can prevent costly issues and keep your vehicle running smoothly.