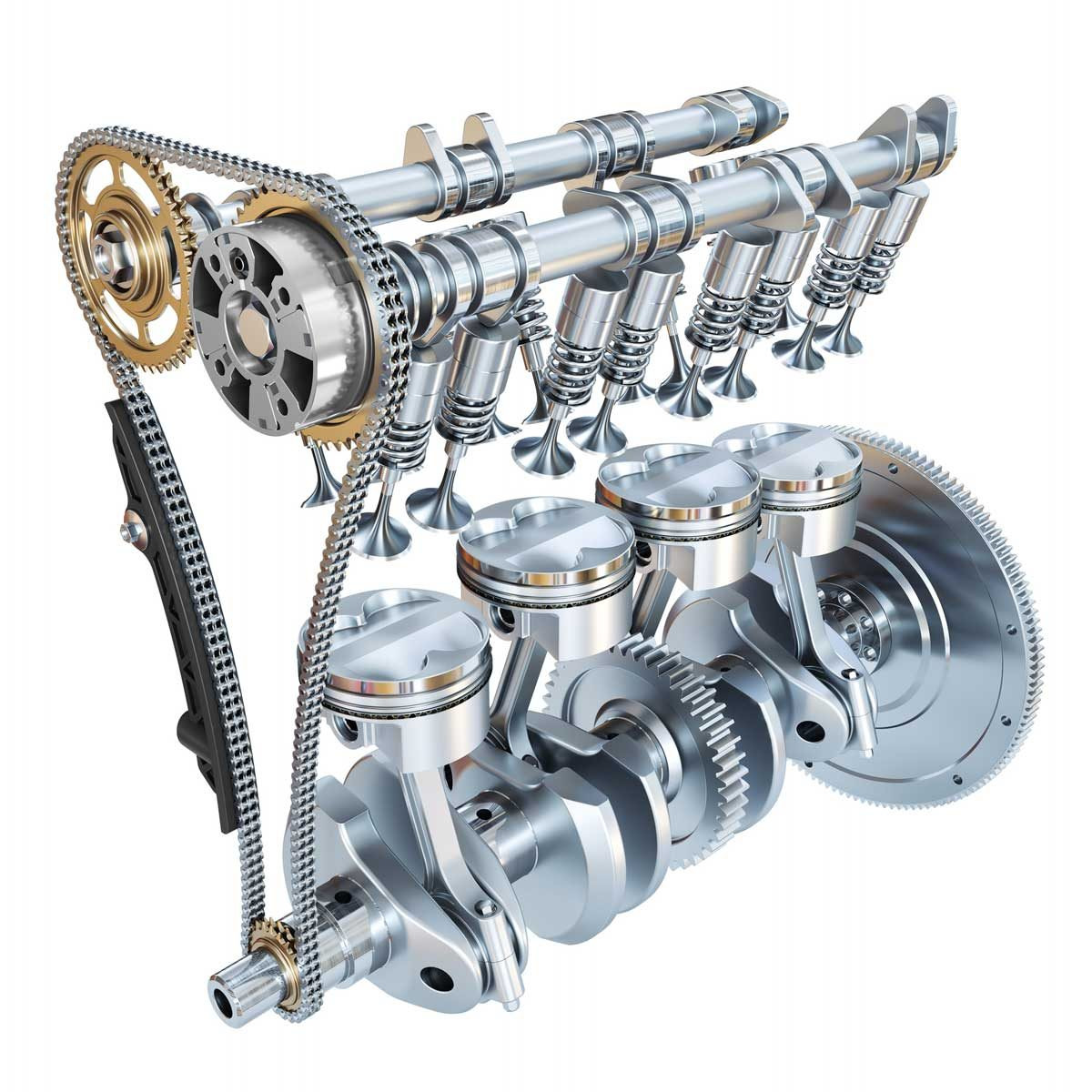

Your car’s engine is a complex system, and it relies on a variety of sensors to function properly. One of the most important sensors is the crankshaft sensor, which measures the position of the crankshaft and sends this information to the engine’s computer. This information is used to control the timing of the engine’s ignition and fuel injection systems.

A faulty crankshaft sensor can cause a variety of problems, including hard starting, stalling, and poor performance. In some cases, a faulty crankshaft sensor can even cause the engine to fail.

If you’re experiencing any of these problems, it’s important to have your car’s crankshaft sensor checked by a qualified mechanic.

What is a Crankshaft Sensor?

The crankshaft sensor is a small, electronic device that is mounted on the engine block. It consists of a magnetic core and a coil of wire. When the crankshaft rotates, the magnetic core moves past the coil of wire, which generates a voltage signal. The voltage signal is sent to the engine’s computer, which uses it to determine the position of the crankshaft.

How Does a Crankshaft Sensor Work?

The crankshaft sensor works by measuring the magnetic field generated by the crankshaft. The magnetic field is generated by the movement of the crankshaft, and it changes in strength as the crankshaft rotates. The crankshaft sensor converts these changes in magnetic field into a voltage signal, which is then sent to the engine’s computer.

History and Myth of Crankshaft Sensor

The crankshaft sensor was first developed in the early 1980s. It was originally used on race cars, but it quickly became a standard feature on production cars. Today, crankshaft sensors are used on all types of vehicles, from small cars to large trucks.

Hidden Secret of Crankshaft Sensor

The crankshaft sensor is a critical component of your car’s engine. It is responsible for sending information about the position of the crankshaft to the engine’s computer. This information is used to control the timing of the engine’s ignition and fuel injection systems.

Recommendation of Crankshaft Sensor

If you are experiencing any of the symptoms of a faulty crankshaft sensor, it is important to have your car diagnosed by a qualified mechanic. A faulty crankshaft sensor can cause a variety of problems, including hard starting, stalling, and poor performance. In some cases, a faulty crankshaft sensor can even cause the engine to fail.

Crankshaft Sensor and Its Importance

The crankshaft sensor is a vital part of your car’s engine. It helps the engine to run smoothly and efficiently. If the crankshaft sensor fails, your car may experience a number of problems, including:

- Hard starting

- Stalling

- Poor performance

- Engine failure

Tips for Crankshaft Sensor Maintenance

There are a few things you can do to help keep your crankshaft sensor in good working order:

- Keep your engine oil clean and changed regularly.

- Inspect the crankshaft sensor for any damage or corrosion.

- Replace the crankshaft sensor if it fails.

Crankshaft Sensor and Troubleshooting

If you are experiencing any of the symptoms of a faulty crankshaft sensor, it is important to have your car diagnosed by a qualified mechanic. A faulty crankshaft sensor can be a serious problem, and it is important to have it fixed as soon as possible.

Fun Facts of Crankshaft Sensor

Here are some fun facts about crankshaft sensors:

- Crankshaft sensors are used on all types of vehicles, from small cars to large trucks.

- Crankshaft sensors were first developed in the early 1980s.

- Crankshaft sensors are a critical component of your car’s engine.

How to Repair a Crankshaft Sensor

If your crankshaft sensor fails, you will need to replace it. Replacing a crankshaft sensor is a relatively simple job that can be done in about an hour. Here are the steps on how to replace a crankshaft sensor:

1. Disconnect the negative battery terminal.

2. Locate the crankshaft sensor. It is usually located on the side of the engine block.

3. Unplug the electrical connector from the crankshaft sensor.

4. Remove the bolt that holds the crankshaft sensor in place.

5. Pull the crankshaft sensor out of the engine block.

6. Install the new crankshaft sensor.

7. Tighten the bolt that holds the crankshaft sensor in place.

8. Plug the electrical connector into the crankshaft sensor.

9. Connect the negative battery terminal.

10. Start the engine and check for leaks.

What If Crankshaft Sensor Fails?

If your crankshaft sensor fails, your car will experience a number of problems, including:

- Hard starting

- Stalling

- Poor performance

- Engine failure

Listicle of Crankshaft Sensor

Here is a listicle of crankshaft sensors:

- Magnetic crankshaft sensor

- Inductive crankshaft sensor

- Hall effect crankshaft sensor

Question and Answer

Here are some frequently asked questions about crankshaft sensors:

- What is a crankshaft sensor?

- How does a crankshaft sensor work?

- What are the symptoms of a faulty crankshaft sensor?

- How do I replace a crankshaft sensor?

Conclusion of Crankshaft Sensor

The crankshaft sensor is a critical component of your car’s engine. It helps the engine to run smoothly and efficiently. If the crankshaft sensor fails, your car may experience a number of problems, including hard starting, stalling, and poor performance. In some cases, a faulty crankshaft sensor can even cause the engine to fail.