Having the right tools for your RV adventures is essential, but what if your RV breaks down in the middle of nowhere? Having a bad crankshaft position sensor can be a nightmare. Learn what the symptoms are and how to fix this problem before it happens.

Don’t let a bad crankshaft position sensor ruin your next RV adventure

A crankshaft position sensor (CPS) is a vital part of your RV’s engine. It monitors the position of the crankshaft and sends this information to the engine’s computer. This information is used to control the timing of the spark plugs and fuel injectors. A bad CPS can cause a variety of problems, including engine misfires, stalling, and difficulty starting. If you think your CPS may be bad, it’s important to have it checked by a qualified mechanic.

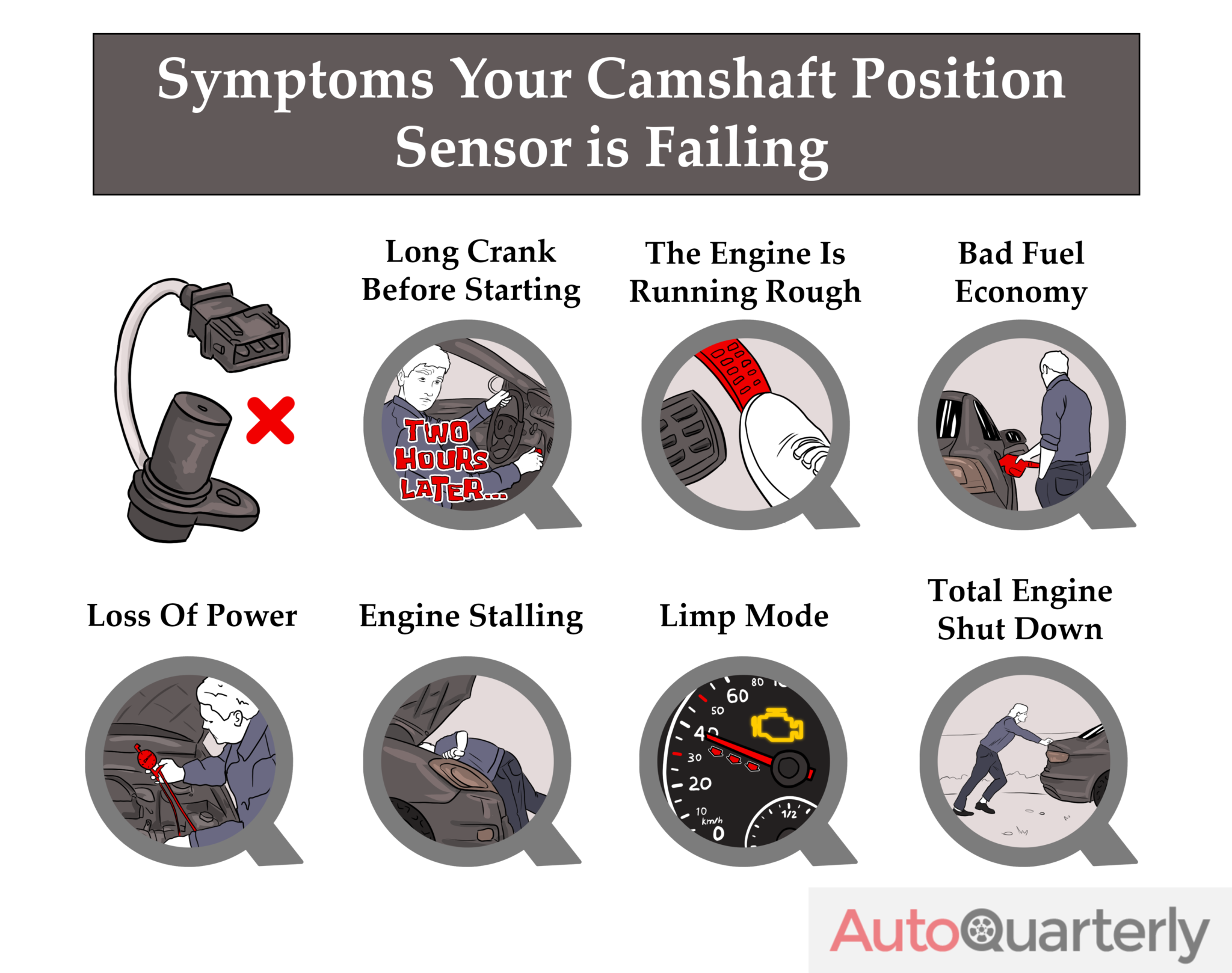

Symptoms of a bad crankshaft position sensor

A bad crankshaft position sensor can cause the engine to misfire because it sends incorrect timing information to the computer. When timing is off, the spark plugs fire at the wrong time, which can lead to a loss of power and acceleration.

If the crankshaft position sensor is not sending the correct information to the computer, the computer may not be able to control the engine’s fuel injection and ignition systems. This can lead to the engine stalling because it is not getting the right amount of fuel or spark.

A faulty crankshaft position sensor can cause difficulty starting the engine because the computer may not be able to determine the correct timing for the spark plugs and fuel injectors. This can lead to the engine cranking but not starting.

Causes of a bad crankshaft position sensor

The crankshaft position sensor may be damaged if it receives too much voltage, which can happen if there is a problem with the wiring or if the sensor is faulty. A bad connection or a short circuit can also cause the sensor to fail.

The crankshaft position sensor may also fail if it is bumped or vibrated too much. This can happen if the engine is not properly mounted or if the sensor is not properly secured.

How to fix a bad crankshaft position sensor

If you have determined that your crankshaft position sensor is bad, it will need to be replaced. This is a relatively simple repair that can be done by most do-it-yourselfers. The new sensor will need to be properly installed and torqued to the correct specifications.

If you are experiencing problems with your crankshaft position sensor, it is important to check the wiring. Make sure that the wires are not frayed or damaged and that the connections are tight. If you find any problems with the wiring, you should repair them before replacing the sensor.

How to prevent a bad crankshaft position sensor

The best way to prevent a bad crankshaft position sensor is to keep your RV well-maintained. This includes regular oil changes and tune-ups. It is also important to check the wiring and connections for the sensor regularly.

Driving in rough conditions can put a lot of stress on the crankshaft position sensor. If you can, avoid driving on rough roads or off-road. If you do have to drive in rough conditions, be sure to drive slowly and carefully.

What are the symptoms of a bad crankshaft position sensor?

A bad crankshaft position sensor can cause the engine to misfire because it sends incorrect timing information to the computer. This can cause the engine to run rough and lose power.

A bad crankshaft position sensor can also cause the engine to stall. This is because the computer may not be able to control the engine’s fuel injection and ignition systems properly.

A bad crankshaft position sensor can make it difficult to start the engine. This is because the computer may not be able to determine the correct timing for the spark plugs and fuel injectors.

What is a crankshaft position sensor?

A crankshaft position sensor (CPS) is a device that monitors the position of the crankshaft in an internal combustion engine. The CPS is used by the engine’s electronic control unit (ECU) to determine the timing of the spark plugs and fuel injectors. A bad CPS can cause a variety of problems, including engine misfires, stalling, and difficulty starting.

History and myth of crankshaft position sensors

The crankshaft position sensor was first introduced in the early 1980s. Prior to this, engines relied on a distributor to determine the timing of the spark plugs. The CPS is a more accurate and reliable way to determine the crankshaft’s position, which has led to improved engine performance and fuel efficiency.

Hidden secret of crankshaft position sensors

The crankshaft position sensor is a relatively simple device, but it plays a vital role in the operation of an internal combustion engine. Without a properly functioning CPS, the engine would not be able to run smoothly or efficiently.

Recommendation of crankshaft position sensors

If you are having problems with your engine, it is important to have the crankshaft position sensor checked. A bad CPS can cause a variety of problems, including engine misfires, stalling, and difficulty starting. Replacing a bad CPS is a relatively simple repair that can be done by most do-it-yourselfers.

What are the symptoms of a bad crankshaft position sensor and related keywords?

A bad crankshaft position sensor can cause the engine to misfire because it sends incorrect timing information to the computer. This can cause the engine to run rough and lose power.

A bad crankshaft position sensor can also cause the engine to stall. This is because the computer may not be able to control the engine’s fuel injection and ignition systems properly.

A bad crankshaft position sensor can make it difficult to start the engine. This is because the computer may not be able to determine the correct timing for the spark plugs and fuel injectors.

Tips of crankshaft position sensors

If you are experiencing problems with your crankshaft position sensor, it is important to check the wiring. Make sure that the wires are not frayed or damaged and that the connections are tight. If you find any problems with the wiring, you should repair them before replacing the sensor.

If the crankshaft position sensor is dirty, it may not be able to function properly. You can clean the sensor with a mild detergent and a soft cloth. Be sure to dry the sensor thoroughly before reinstalling it.

What are the symptoms of a bad crankshaft position sensor and related keywords?

A bad crankshaft position sensor can cause the engine to misfire because it sends incorrect timing information to the computer. This can cause the engine to run rough and lose power.

A bad crankshaft position sensor can also cause the engine to stall. This is because the computer may not be able to control the engine’s fuel injection and ignition systems properly.

A bad crankshaft position sensor can make it difficult to start the engine. This is because the computer may not be able to determine the correct timing for the spark plugs and fuel injectors.

Fun Facts of crankshaft position sensors

Without a properly functioning CPS, the engine would not be able to run smoothly or efficiently.

It is usually held in place by a bracket or bolt.

It generates a signal by sensing the magnetic field produced by the crankshaft.

How to replace a crankshaft position sensor

Replacing a crankshaft position sensor is a relatively simple repair that can be done by most do-it-yourselfers. Here are the steps involved:

This will prevent any electrical shock.

It is usually located on the engine block near the crankshaft.

Use a small screwdriver or your fingers to release the connector.